7-113

COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

7. TROUBLESHOOTING IMAGE FAULTS/MALFUNCTIONS

21

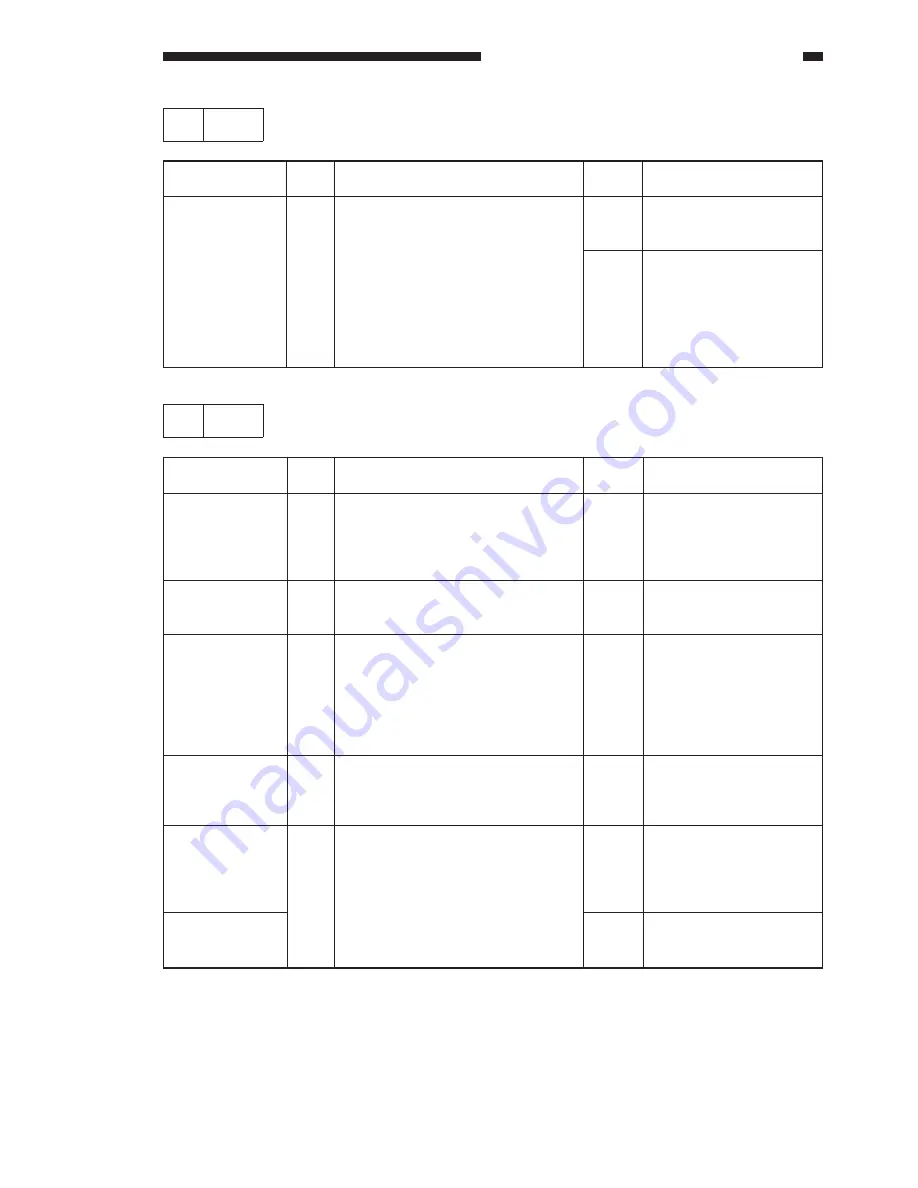

E073

22

E074

Cause

Transfer belt

lifter sensor 1

(PS12), 2 (PS13)

Operation

(faulty)

Sensor (position)

Pick-up motor

Transfer belt

lifter clutch

(CL17)

DC controller

PCB

Cause

Transfer frame

drawer connec-

tor, DC controller

PCB

Step

1

Checks

Is the transfer frame drawer connec-

tor soiled with toner or damaged?

Yes/No

YES

NO

Action

Clean and replace the

drawer connector.

Check the wiring from

J2218 on the DC control-

ler PCB to the transfer

frame drawer connector

J6122; if normal, replace

the DC controller PCB.

Step

1

2

3

4

5

Checks

Is the sensor normal? (See the

instructions on how to check

photointerrupters.)

Turn the transfer belt lifter drive shaft

by a finger. Does it turn smoothly?

Turn OFF and ON the power switch

to clear ‘E074’.

Press the Start key, and check the

operation of the lifter of the transfer

belt by the eye. Does the transfer

belt move up and down?

Turn OFF and ON the power switch

once again, and press the Start key.

Does the pick-up motor rotate?

Turn OFF and ON the power switch

once again, and press the Start key.

Does the voltage between J2226A-5

and J2226A-4 on the DC controller

PCB change from 0 V to 24 V?

Yes/No

NO

NO

YES

NO

YES

NO

Action

Replace the sensor.

Remove the cause of the

faulty rotation.

Check the position of the

sensor; if normal, replace

the DC controller PCB.

Check the wiring; if

normal, replace the pick-

up motor.

Check the wiring from the

clutch to the DC controller

PCB; if normal, replace

the clutch.

Replace the DC controller

PCB.

Summary of Contents for 1000S

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper ...