4.2.2 Switch setting and confirmation

Switch setting is required only the following four kinds of

system configuration.

1

MAIN UNIT (B/W, COLOR) + 5" FDD

2

MAIN UNIT (B/W, COLOR) + 8" FDD

3

MAIN UNIT (B/W, COLOR) + 5" FDD + 8” FDD

4

MAIN UNIT (B/W, COLOR) + 8" FDD + 8" FDD

Necessary to confirm and set the switches in the P.C.B according

to each system configuration.

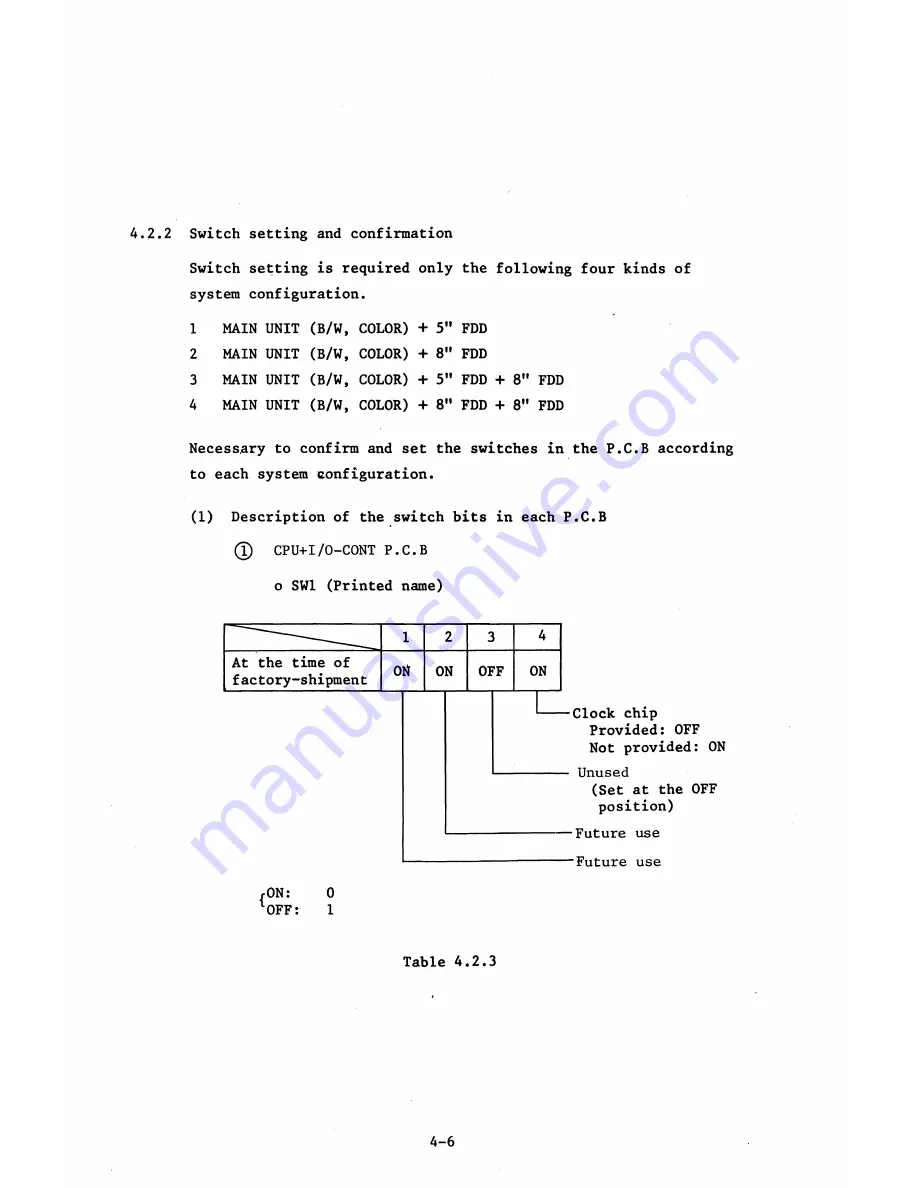

(1) Description of the switch bits in each P.C.B

(I)

CPU+I/O-CONT P.C.B

o SW1 (Printed name)

Clock chip

Provided: OFF

Not provided: ON

Unused

(Set at the OFF

position)

■Future use

Future use

rON:

0

lOFF:

1

Table 4.2.3

Summary of Contents for AS-100M

Page 1: ...Canon FIELD SERVICE MANUAL ...

Page 26: ...2 2 5 FDD Media Canon specified MDD 512DD 512B sector 2 3 ...

Page 30: ...ICURRENT LÖÖPl Available soon 2 7 ...

Page 39: ...3 3 5 FDD 3 3 1 External View Housing plate Fig 3 3 1 Fig 3 3 2 3 5 ...

Page 41: ...3 4 8 FDD 3 4 1 External View Housing Fig 3 4 1 Fig 3 4 2 3 7 ...

Page 43: ...3 5 PRINTER Refer to PRINTER TECHNICAL GUIDE 3 9 ...

Page 47: ... 2 KEYBOARD 3 5 FDD 4 3 ...

Page 48: ... 8 FDD 4 4 ...

Page 100: ...8 FDD Fuse 1 Replace two 5A fuses 8 FDD as In Fig 5 5 7 5 23 ...

Page 107: ...Chapter 7 Troubleshooting 7 1 At System Up 7 1 ...

Page 129: ...Chapter 8 Appendix 8 1 Unit Configuration and General Wiring ...

Page 130: ...8 1 Unit Configurations and General Wiring 8 1 POWER SWITCH ...

Page 135: ...Fig 8 1 6 8 FDD For 115 120 230 240V POWER SWITCH ...

Page 136: ...CANON INC COPYRIGHT g 198 BY CANON INC Printed in Japan Feb 1983 E Y 8 6 0 7 2 2 2 2 ...