Part 2: Maintenance

BJC-3000

2-14

2.5.3 When EEPROM setting is required

Replacing the control board and the waste ink absorber requires resetting the

EEPROM, setting the model, and confirmation with the test printout.

The EEPROM (IC502) keeps track of data that is native to the machine, including the

waste ink amount and the model settings.

Refer to

Part 3: 2.1 Service Mode Operations (Page 3-8

) for the operation procedures.

(1) After Control Board Replacement

When replacing the control board, the waste ink absorber must also be replaced if

the waste ink amount exceeds 7%. Also, the EEPROM needs to be reset and model

setting must be performed.

Confirmation of the waste ink amount can be carried out with the service/factory

test print before replacing the control board, or by visually checking the waste ink

absorber.

The memory data for the replacement control board (EEPROM) is not defined.

If the EEPROM is not reset, the waste ink level may exceed the waste ink absorber

capacity without causing the waste ink full error.

(2) After Waste Ink Absorber Replacement

Reset the EEPROM's total waste ink amount to zero.

After the EEPROM is reset, the data it contained cannot be confirmed with

the test printout. Be sure to check the stored data before resetting the

EEPROM.

When the stored data is reset, the various settings, such as the total count

of sheets passed, and the total waste ink amount will be reset, however,

the model setting will remain.

Data on the EEPROM before replacement, including various settings and

the total waste ink amount, cannot be written to the new EEPROM.

When the waste ink-full error occurs, it can be assumed that the printer

has printed more sheets than its service life called for. However, this

depends on how many times the power has been turned on/off, the

cartridge has been replaced (the number of times the front cover is

opened), and the usage conditions.

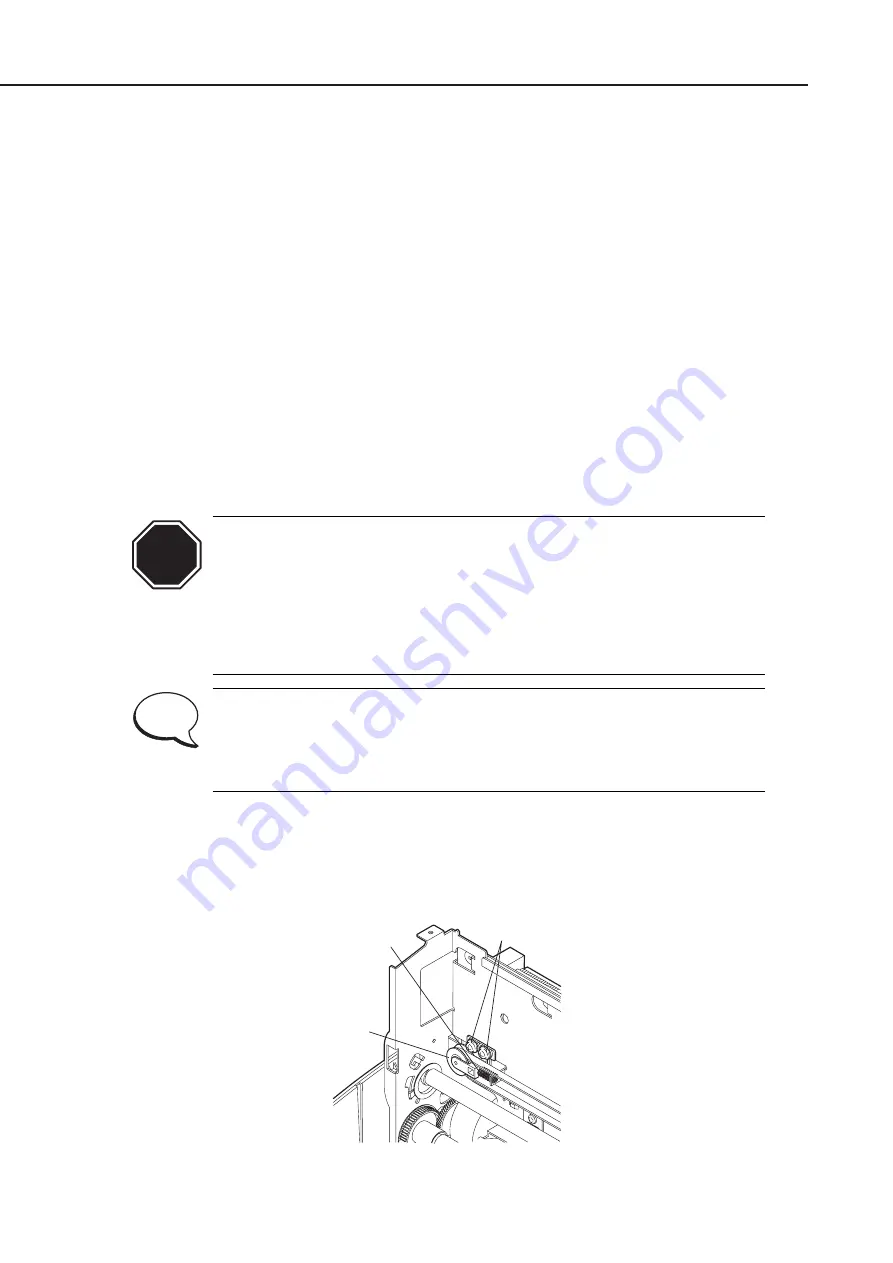

2.5.4 When the carriage belt tension needs adjustment

When tension on the carriage belt has been loosened, for example, to remove the

carriage, the carriage belt tension needs to be adjusted.

Use the tension spring tool (QY9-0043) when fixing the pulley assembly before

tightening the screws. Remove the tension spring after the screws are fixed.

NOTE

Figure 2-15 Carriage Belt Tension Adjustment

Fixing Screws

Tension Spring

Idler Pulley

CAUTION

Summary of Contents for BJC-3000 Series

Page 2: ...0899 SC 0 30 0 ...

Page 3: ......

Page 12: ...VIII This page intentionally left blank ...

Page 14: ......

Page 28: ......

Page 48: ...Part 2 Maintenance BJC 3000 2 20 This page intentionally left blank ...

Page 50: ......

Page 62: ...Part 3 Operation BJC 3000 3 12 This page intentionally left blank ...

Page 64: ......

Page 88: ......

Page 95: ......

Page 112: ...Part 5 Appendix BJC 3000 5 24 This page intentionally left blank ...

Page 118: ......

Page 119: ...PRINTED IN JAPAN IMPRIME AU JAPON CANON INC The printing paper contains 70 waste paper ...