<Cause> · The paper-feed operation is executed but the paper is

not fed.

· The paper-eject operation is executed but the paper is

not ejected.

<Suspected Parts> Paper feed parts, paper end sensor, control

board

<Measures>

Part 4: Troubleshooting

BJC-3000

4-12

ts

board

Yes

No

Visual check of the

paper feed parts

Correct?

Next

Page

Visually check for paper jams.

Check for gear deformation, damage or chipping.

Verify the paper selector lever setting.

See

Part 1: 2.2.2 Paper type/setting (Page 1-4)

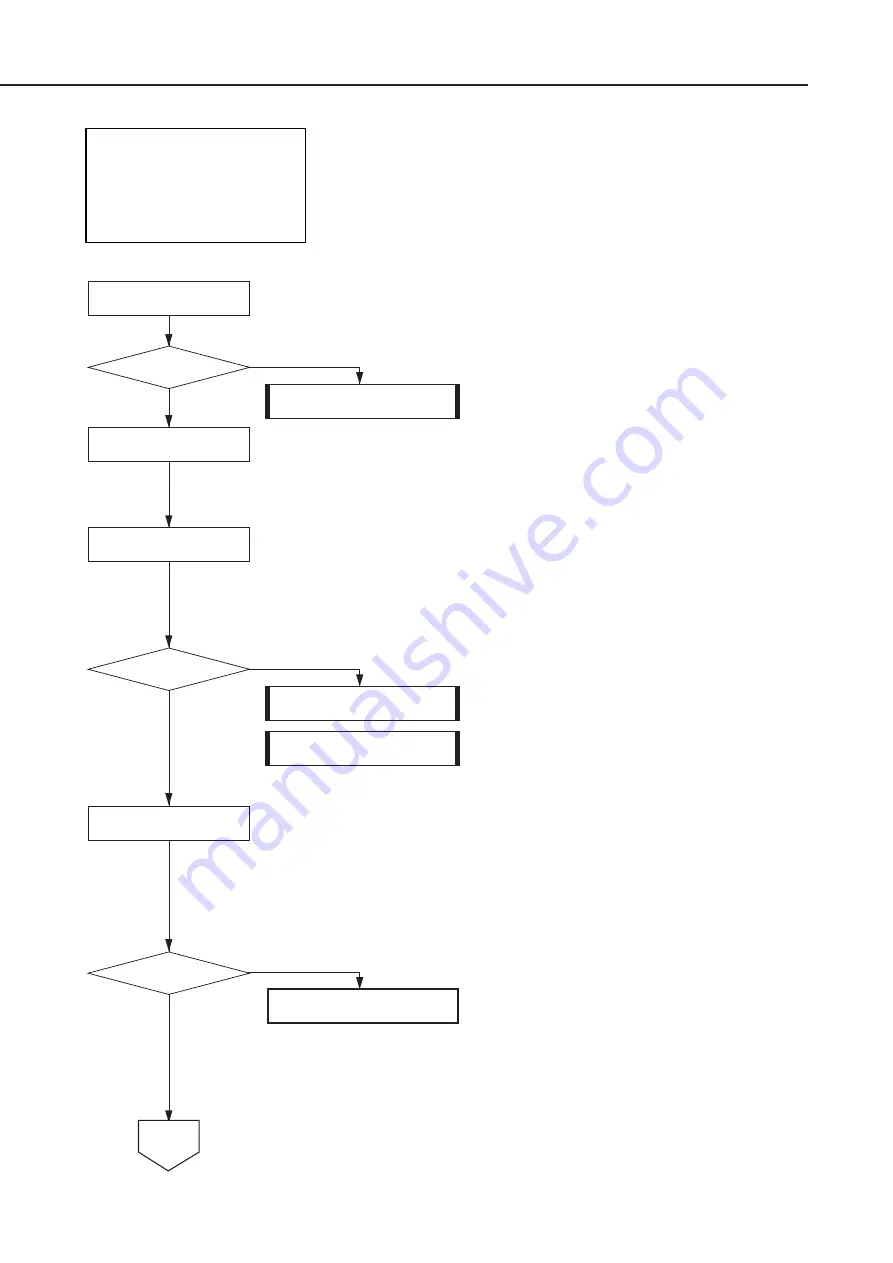

Check for any abnormal

contamination, wear, deterioration

of the pick-up roller's rubber ring

or separation sheet, cam

dislocation, gear deformation or

damage, mylar damage, etc..

Repair/replace faulty parts

Power on with the cover

opened

No

Yes

No

Correct?

Auto sheet feeder unit check

Paper feed check

Check for the proper paper feed from the auto sheet feeder when

the pick-up roller rotates.

Yes

Correct?

Repair/replace faulty par

Replace the control

Paper feed parts

operation check

Check for the proper rotations of paper feed motor, pick-up

roller, eject rollers, etc., during initialization.

Any abnormal noise?

Is the paper feed motor out of sync?

10. Paper Feed

Error/

Paper Jam

Summary of Contents for BJC-3000 Series

Page 2: ...0899 SC 0 30 0 ...

Page 3: ......

Page 12: ...VIII This page intentionally left blank ...

Page 14: ......

Page 28: ......

Page 48: ...Part 2 Maintenance BJC 3000 2 20 This page intentionally left blank ...

Page 50: ......

Page 62: ...Part 3 Operation BJC 3000 3 12 This page intentionally left blank ...

Page 64: ......

Page 88: ......

Page 95: ......

Page 112: ...Part 5 Appendix BJC 3000 5 24 This page intentionally left blank ...

Page 118: ......

Page 119: ...PRINTED IN JAPAN IMPRIME AU JAPON CANON INC The printing paper contains 70 waste paper ...