5

5

5-53

5-53

Adjustment > Adjustment at Time of Parts Replacement > Adjustment After Replacing Finisher Controller PCB

Adjustment > Adjustment at Time of Parts Replacement > Adjustment After Replacing Finisher Controller PCB

20)

Correct the position of the stopper fixture according to the displacement amount (C)

for folding position that was measured in step 1).

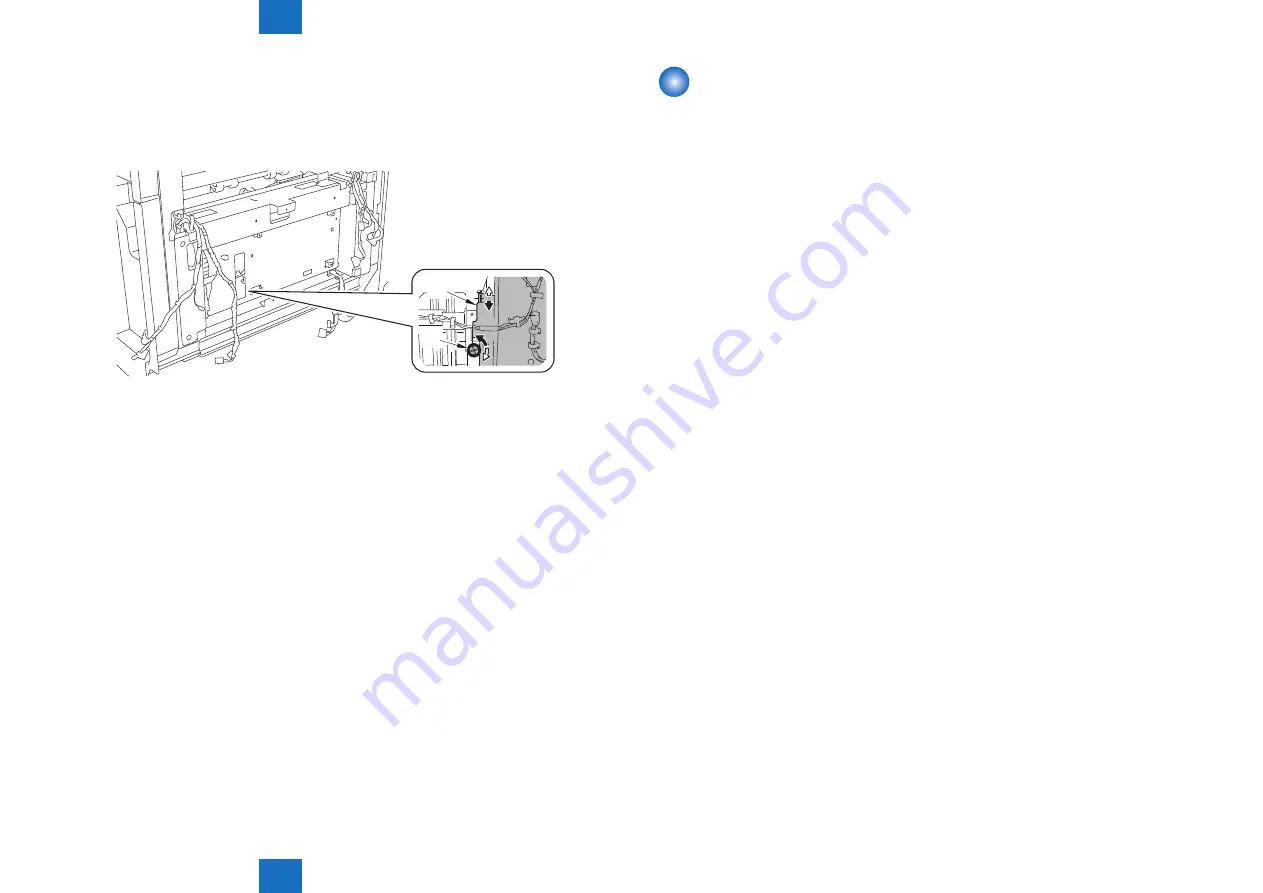

Procedure: Turn the cross-hole screw [1] to adjust the position of the lead edge stopper

fixture [2] upward/downward.

(0.5mm-change per turn)

[1]

[2]

21)

After the adjustment is completed, tighten the fixing screw of the lead edge stopper.

22)

Output the paper from the saddle assembly and check the result.

F-5-124

Adjustment After Replacing Finisher Controller PCB

Execute this adjustment when replacing the finisher controller PCB.

1) Execute the following adjustments:

• Adjusting Sensor Light Intensity

• Adjusting the Alignment Position of the Upper Neat Alignment Plate

• Adjusting the Alignment Position of the Lower Neat Alignment Plate

• Adjusting the Height of Corrugation Roller for Stack Delivery

• Adjusting Alignment Plate Position

• Adjusting Staple Position (1-stapling at the rear)

• Adjusting Staple Position (1-stapling at the front)

• Adjusting Staple Position (2-stapling positions)

• Adjusting Delivery of Staple Stack (lower delivery)

• Adjusting Delivery of Staple Stack (saddle delivery)

• Adjusting Delivery of Staple Stack (lower delivery)

• Adjusting Delivery of Staple Stack (saddle delivery)

• Adjusting Position of Saddle Lead Edge Stopper

• Adjusting Saddle Stitching Position

• Adjusting Saddle Folding Position

• Bufferless Mode

• Adjustment in the Case of Failure in Stacking Performance of Tray (upper curl)

• Adjustment in the Case of Failure in Stacking Performance of Tray (lower curl)

• Adjustment in the Case of Failure in Stacking Performance of Tray (run-on of paper

Summary of Contents for Booklet Finisher-D1

Page 12: ... Notes Before Servicing Points to Note at Cleaning Safety Precautions ...

Page 14: ...1 1 Product Outline Product Outline Product Specifications Names of Parts ...

Page 60: ...3 3 Periodic Servicing Periodic Servicing User Maintenance Maintenance and Inspection ...

Page 315: ...6 6 Troubleshooting Troubleshooting Upgrading ...

Page 357: ... Service Tools Solvents and Oils List of Signals General Circuit Diagram Appendix ...