Chapter 7

7-39

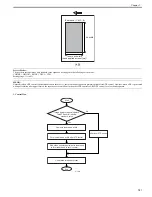

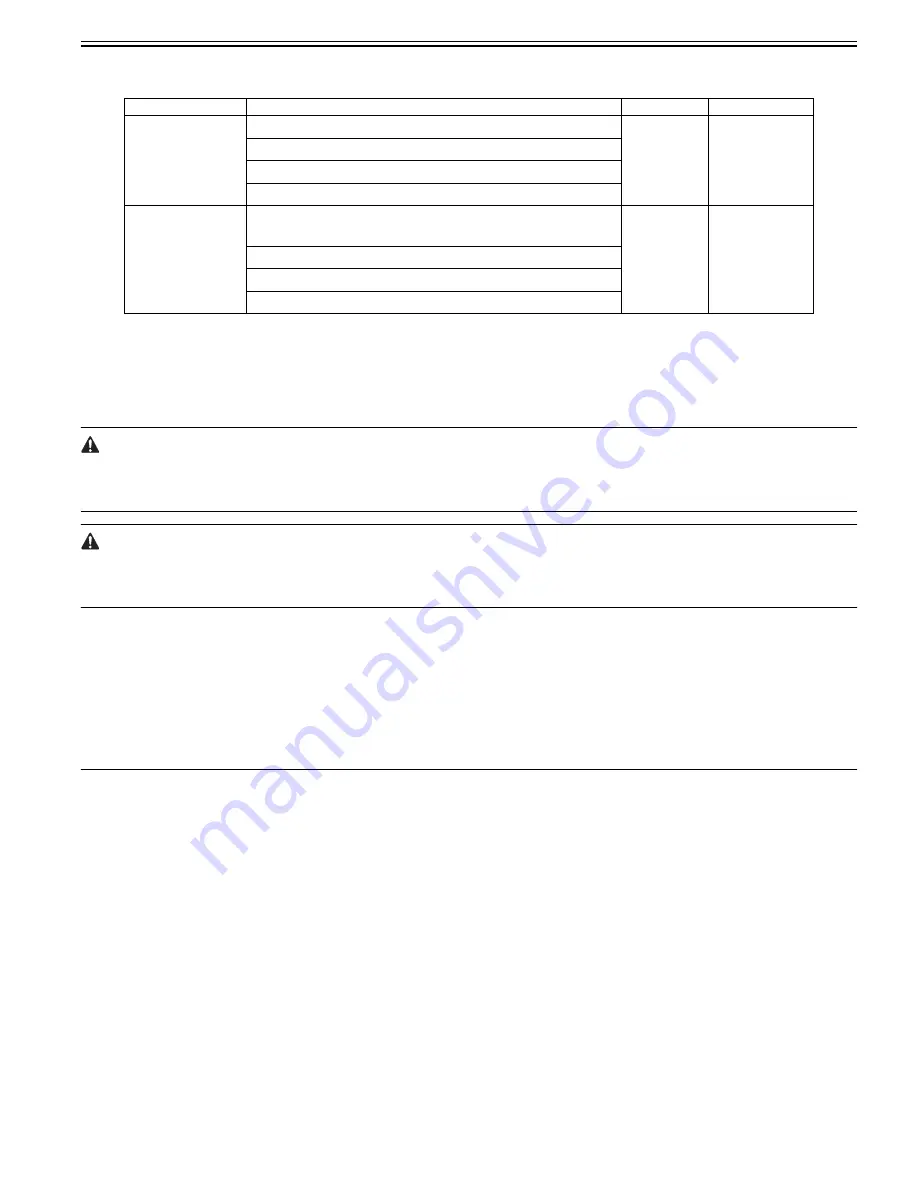

If the toner residual level is less than the specified value, DC controller notices two kinds of messages (toner absence notice, toner absence) to video controller.

The following is the relationship between the display message and the toner residual level.

T-7-14

2. Detection by toner refill quantity detection sensor

This detection sequence works out the quantity of remaining toner from the outputs of the toner refill quantity detection sensors (PS3 to 6) and displays the quantity

on the touch panel in units of 1%. The sequence is performed when power is turned ON, upon image formation (for each 1% of consumption), when toner has run

out (0% notification) or when the toner status changes from no toner to toner present.

When toner is absence, the printing operation of the main body is stopped.

The toner feed level per one block varies, so the toner residual information is just a target. When the toner residual becomes 1% or less, the residual information is

not displayed on the touch panel and 0% is displayed at the time of the toner absence.

When toner is absence, the printing operation of the main body is stopped.

The toner feed level per one block varies, so the toner residual information is just a target. When the toner residual becomes 1% or less, the residual information is

not displayed on the touch panel and 0% is displayed at the time of the toner absence.

7.6.4 Toner Container Detection

0014-3282

Color iR C3380G / Color iR C2880G / Color iR C3380i / Color iR C3380 / Color iR C2880i / Color iR C2880 / iR C3480 / iR C3480i / iR C3080 / iR C3080i / iR

C2550

The device does not have toner container detection.

Even if there is no toner container in the device, there will be residual toner in the refill screw, etc., so printing can continue for a few more sheets. If printing is

continued for just a few sheets, there should be no problem as regards image quality.

Then, the piezo-sensor that carries out the remaining toner quantity detection will detect toner out and will stop the print operation.

7.7 Transfer Unit

7.7.1 Outline of the Transfer Unit

7.7.1.1 Overview

0013-8506

Color iR C3380G / Color iR C2880G / Color iR C3380i / Color iR C3380 / Color iR C2880i / Color iR C2880 / iR C3480 / iR C3480i / iR C3080 / iR C3080i / iR

C2550

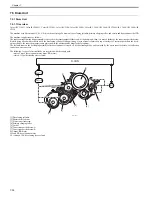

The transfer assembly is divided into the primary transfer block and the secondary transfer block.

The primary transfer block serves to move toner from the photosensitive drum to the ITB, while the secondary transfer block functions to move toner from the ITB

to print paper.

The transfer assembly consists of the following components: ITB cleaning unit, ITB, primary transfer roller, primary transfer roller, secondary toner inside roller,

tension roller, secondary transfer outside roller.

Message type

Message Descriptio

Toner Level

Detected by:

Toner absence notice

"Black toner is low. Replacement not yet needed."

10%

Toner feed level sensor

"Yellow toner is low. Replacement not yet needed. "

"Magenta toner is low. Replacement not yet needed."

"Cyan toner is low. Replacement not yet needed."

Abcence of toner

"Replace toner container. (Black)"

0%

piezo sensor

"Replace toner container. (Yellow) "

"Replace toner container. (Magenta) "

"Replace toner container. (Cyan) "

Summary of Contents for CiRC2550

Page 2: ......

Page 27: ...Chapter 1 Introduction ...

Page 28: ......

Page 47: ...Chapter 1 1 18 F 1 14 ON OFF ON OFF ...

Page 70: ...Chapter 1 1 41 5 Turn on the main power switch ...

Page 79: ...Chapter 2 Installation ...

Page 80: ......

Page 85: ...Chapter 2 2 3 Not available in some regions ...

Page 134: ...Chapter 3 Basic Operation ...

Page 135: ......

Page 137: ......

Page 143: ...Chapter 4 Main Controller ...

Page 144: ......

Page 152: ...Chapter 4 4 6 F 4 6 CPU HDD ROM access to the program at time of execution ...

Page 171: ...Chapter 5 Original Exposure System ...

Page 172: ......

Page 203: ...Chapter 6 Laser Exposure ...

Page 204: ......

Page 206: ......

Page 220: ...Chapter 7 Image Formation ...

Page 221: ......

Page 277: ...Chapter 8 Pickup Feeding System ...

Page 278: ......

Page 282: ......

Page 336: ...Chapter 9 Fixing System ...

Page 337: ......

Page 339: ......

Page 357: ...Chapter 10 Externals and Controls ...

Page 358: ......

Page 362: ......

Page 366: ...Chapter 10 10 4 F 10 2 F 10 3 FM1 FM2 FM5 FM8 FM11 FM4 FM3 FM6 FM7 FM9 FM10 ...

Page 375: ...Chapter 10 10 13 F 10 10 2 Remove the check mark from SNMP Status Enabled ...

Page 376: ...Chapter 10 10 14 F 10 11 ...

Page 402: ...Chapter 11 MEAP ...

Page 403: ......

Page 405: ......

Page 452: ...Chapter 12 RDS ...

Page 453: ......

Page 455: ......

Page 464: ...Chapter 13 Maintenance and Inspection ...

Page 465: ......

Page 467: ......

Page 469: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4 ...

Page 474: ...Chapter 14 Standards and Adjustments ...

Page 475: ......

Page 477: ......

Page 485: ......

Page 486: ...Chapter 15 Correcting Faulty Images ...

Page 487: ......

Page 495: ...Chapter 15 15 4 F 15 2 COLOR M 1 COLOR Y C K 0 ...

Page 569: ...Chapter 15 15 78 F 15 82 J102 J107 J103 J108 J101 J109 J106 J112 J115 J113 J114 J104 J105 ...

Page 570: ...Chapter 16 Self Diagnosis ...

Page 571: ......

Page 573: ......

Page 600: ...Chapter 17 Service Mode ...

Page 601: ......

Page 603: ......

Page 712: ...Chapter 18 Upgrading ...

Page 713: ......

Page 715: ......

Page 746: ...Chapter 19 Service Tools ...

Page 747: ......

Page 749: ......

Page 752: ...APPENDIX ...

Page 774: ......