Chapter 19

19-2

[Ctgr]

A: Must be kept by each service engineer.

B: Must be kept by each group of about five engineers.

C: Must be kept by each warkshop.

19.1.2 Solvents and Oils

0014-3038

Color iR C3380G / Color iR C2880G / Color iR C3380i / Color iR C3380 / Color iR C2880i / Color iR C2880 / iR C3480 / iR C3480i / iR C3080i / iR C2550

T-19-2

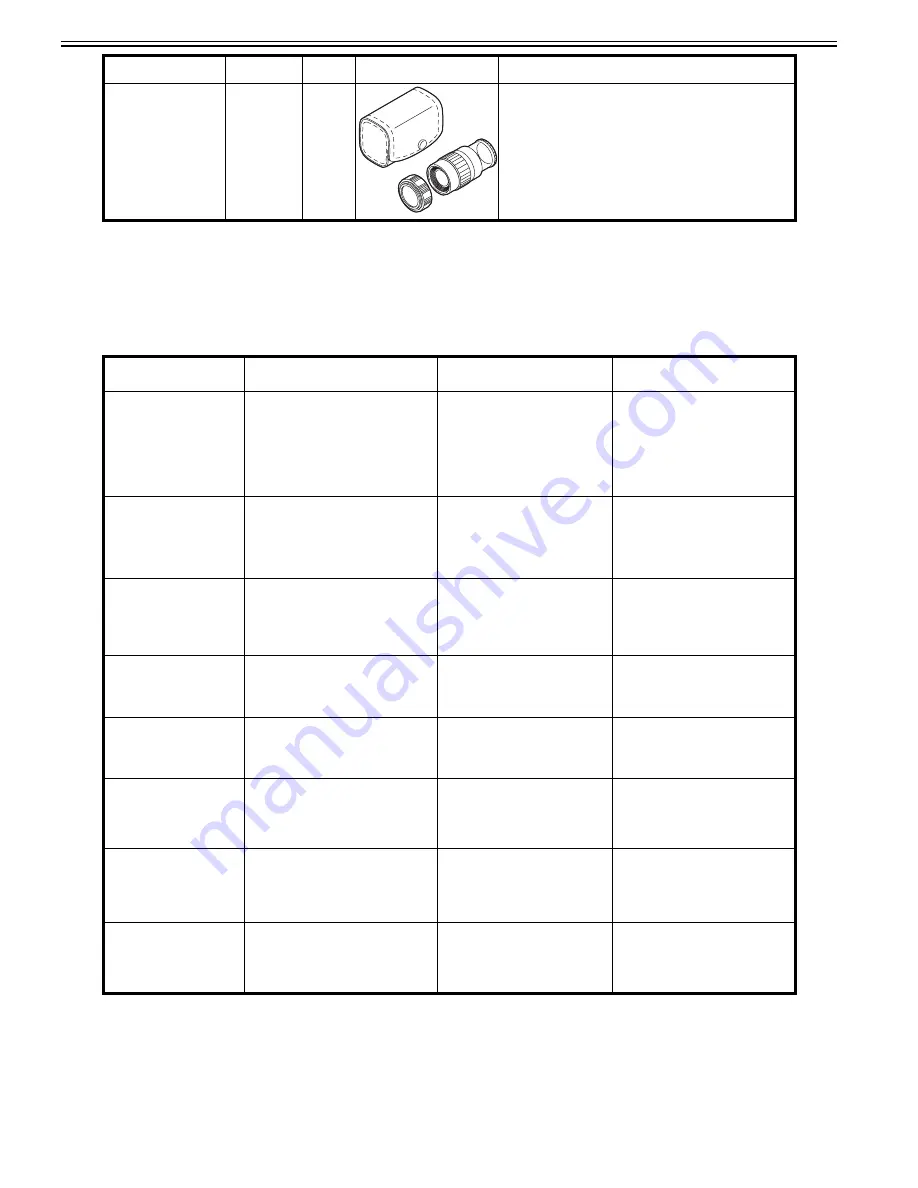

Loupe

CK-0056

B

Used for checking images.

Item

Uses

Composition

Remarks

Alcohol

Cleaning; e.g.,

glass, plastic, ruber; external covers.

-Fluoride-family hydrocarbon

-Alcohol

-Surface activating

-Water

-Do not bring ner fire.

-Procure locally.

-Substitute:

IPA(isopropy alcohol)

Solvent

Cleaning; e.g.,

metal; oil or toner stain.

-Fluoride-family hydrocarbon

-Chlorine-family hydrocarbon

-Alcohol

-Do not bring ner fire.

-Procure locally.

-Substitute:

MEK

Heat-resisting grease

Lubrication; e.g., fixing drive areas.

-Mineral oil-family lithium soap

-Molybdenum disulfide

-MO-138S

-Tool No: CK-0427 (500 g/can)

Lubricating oil

-Mineral oil

(paraffin-family)

-Tool No: CK-0524 (100 cc)

Lubricating oil

Lubrication; e.g., drive areas, friction areas. -Silicone oil

-Tool No: CK-0551 (20 g)

Lubricating oil

(EM-50L)

Lubrication; e.g., gears.

-Special oil

-Special solid lubricating agent

-Lithium soap

-Tool No: HY9-0007

Libricating oil

Lubrication; e.g., scanner rail.

-Silicone oil

-Tool No: 9-6011 (50 cc)

Lubricant

Lubrication; e.g., ITB Cleaning Brade

Fluorine graphite

-Tool No: TKN-0480

Tool name

Tool No.

Ctgr

Appearance

Remarks

Summary of Contents for CiRC2550

Page 2: ......

Page 27: ...Chapter 1 Introduction ...

Page 28: ......

Page 47: ...Chapter 1 1 18 F 1 14 ON OFF ON OFF ...

Page 70: ...Chapter 1 1 41 5 Turn on the main power switch ...

Page 79: ...Chapter 2 Installation ...

Page 80: ......

Page 85: ...Chapter 2 2 3 Not available in some regions ...

Page 134: ...Chapter 3 Basic Operation ...

Page 135: ......

Page 137: ......

Page 143: ...Chapter 4 Main Controller ...

Page 144: ......

Page 152: ...Chapter 4 4 6 F 4 6 CPU HDD ROM access to the program at time of execution ...

Page 171: ...Chapter 5 Original Exposure System ...

Page 172: ......

Page 203: ...Chapter 6 Laser Exposure ...

Page 204: ......

Page 206: ......

Page 220: ...Chapter 7 Image Formation ...

Page 221: ......

Page 277: ...Chapter 8 Pickup Feeding System ...

Page 278: ......

Page 282: ......

Page 336: ...Chapter 9 Fixing System ...

Page 337: ......

Page 339: ......

Page 357: ...Chapter 10 Externals and Controls ...

Page 358: ......

Page 362: ......

Page 366: ...Chapter 10 10 4 F 10 2 F 10 3 FM1 FM2 FM5 FM8 FM11 FM4 FM3 FM6 FM7 FM9 FM10 ...

Page 375: ...Chapter 10 10 13 F 10 10 2 Remove the check mark from SNMP Status Enabled ...

Page 376: ...Chapter 10 10 14 F 10 11 ...

Page 402: ...Chapter 11 MEAP ...

Page 403: ......

Page 405: ......

Page 452: ...Chapter 12 RDS ...

Page 453: ......

Page 455: ......

Page 464: ...Chapter 13 Maintenance and Inspection ...

Page 465: ......

Page 467: ......

Page 469: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4 ...

Page 474: ...Chapter 14 Standards and Adjustments ...

Page 475: ......

Page 477: ......

Page 485: ......

Page 486: ...Chapter 15 Correcting Faulty Images ...

Page 487: ......

Page 495: ...Chapter 15 15 4 F 15 2 COLOR M 1 COLOR Y C K 0 ...

Page 569: ...Chapter 15 15 78 F 15 82 J102 J107 J103 J108 J101 J109 J106 J112 J115 J113 J114 J104 J105 ...

Page 570: ...Chapter 16 Self Diagnosis ...

Page 571: ......

Page 573: ......

Page 600: ...Chapter 17 Service Mode ...

Page 601: ......

Page 603: ......

Page 712: ...Chapter 18 Upgrading ...

Page 713: ......

Page 715: ......

Page 746: ...Chapter 19 Service Tools ...

Page 747: ......

Page 749: ......

Page 752: ...APPENDIX ...

Page 774: ......