1-9

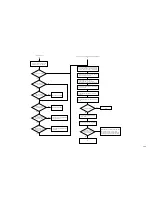

1. Check the transfer charging system.

2. Clean the dust-proofing glass.

3. Clean and check the developing

assembly butting roll.

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

NO

YES

NO

YES

YES

NO

YES

NO

NO

YES

YES

NO

YES

NO

YES

NO

Conditions

· copy density at '5'

· text/photo mode

Select OPTION>BODY>PASCAL=0

in service mode.

Check the height of

each charging wire.

Clean the charging wires.*

*If the primary charging

wire is soiled, replace it.

Make sample copies using TEST in

service mode for the following:

0. normal image using Test Sheet

1. PGTEST=4 using M mono color

2. PGTEST=4 using C mono color

3. PGTEST=4 using Y mono color

4. PGTEST=4 using Bk mono color

5. PGTEST=10

6. PGTEST=5 DENS 48

7. PGTEST=14 photo mode

(TXPH:1)

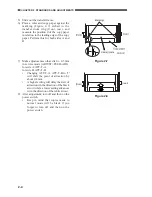

Adjusting the Left/Right Density Slope

Correcting Difference in Density

Make a copy of

the Test Sheet.

Is the density different

between front

and rear?

Is the

density different

between front and rear on

the sample copy made

at PGTYPE=

10 or 5?

Is the difference

in density different from

one color to another?

Is the difference in

density gone?

Is the density higher

(darker) at the rear?

Check the coating of toner on the

developing cylinder. Check the

developing assembly butting roll

and the photosensitive drum butting

block. Clean them if soiled with toner.

Turn the adjusting screw

at the front of the primary

charging assembly

counterclockwise.

Execute test printing at

PGTYPE=10 or 5.

Turn the adjusting screw

at the front of the primary

charging assembly

clockwise.

Is the difference in

density gone?

Check to find out if the copyboard

glass is riding over something.

Clean the scanning lamp, reflecting

plate, mirror, standard white plate,

and copyboard glass.

Execute ADJUST>CCD>CCD-ADJ

in service mode.

Is the difference in

density gone?

Check the original scanning lamp.

Is the darkest

area of the test print

made for a 16-gradation

check too light?

Does the density

become lower (lighter)

gradually in continuous

copying mode?

Is the density low (light)

in all colors?

Execute FUNCTION>DPC>DPC

in service mode.

Is the value of

DISPLAY>DPOT>V00-500,

V00-700 normal?

Open the hopper, and insert the

door switch actuator. Check the

temperature and humidity using

DISPLAY>ANALOG>TEMP,

HUM in service mode.

Are the

temperature and humidity

readings normal?

Check the environment sensor.

To [A] of next page.

Check the high-voltage output of

the internal/external static eliminator.

Is the value

of ADJUST>DENS identical

with the value on

the label?

To [B] of next page.

Enter the data once again, and

make 50 copies.

Check the laser shutter and the

laser system.

Reference (normal values)

V00-500: 430 to 570

V00-700: 600 to 800

1. Check the insulating sheet of the

transfer blade for scratches and

peeling.

2. Check the shaft of the transfer

drum for play.

3. Check the cable inside the transfer

drum.

D. Image Adjustment Basic Procedure