1-10

NO

YES

NO

YES

YES

NO

YES

NO

NO

YES

*Do not clean the grid plate.

YES

NO

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

[B]

[A]

Check the locked condition of the

developing assembly.

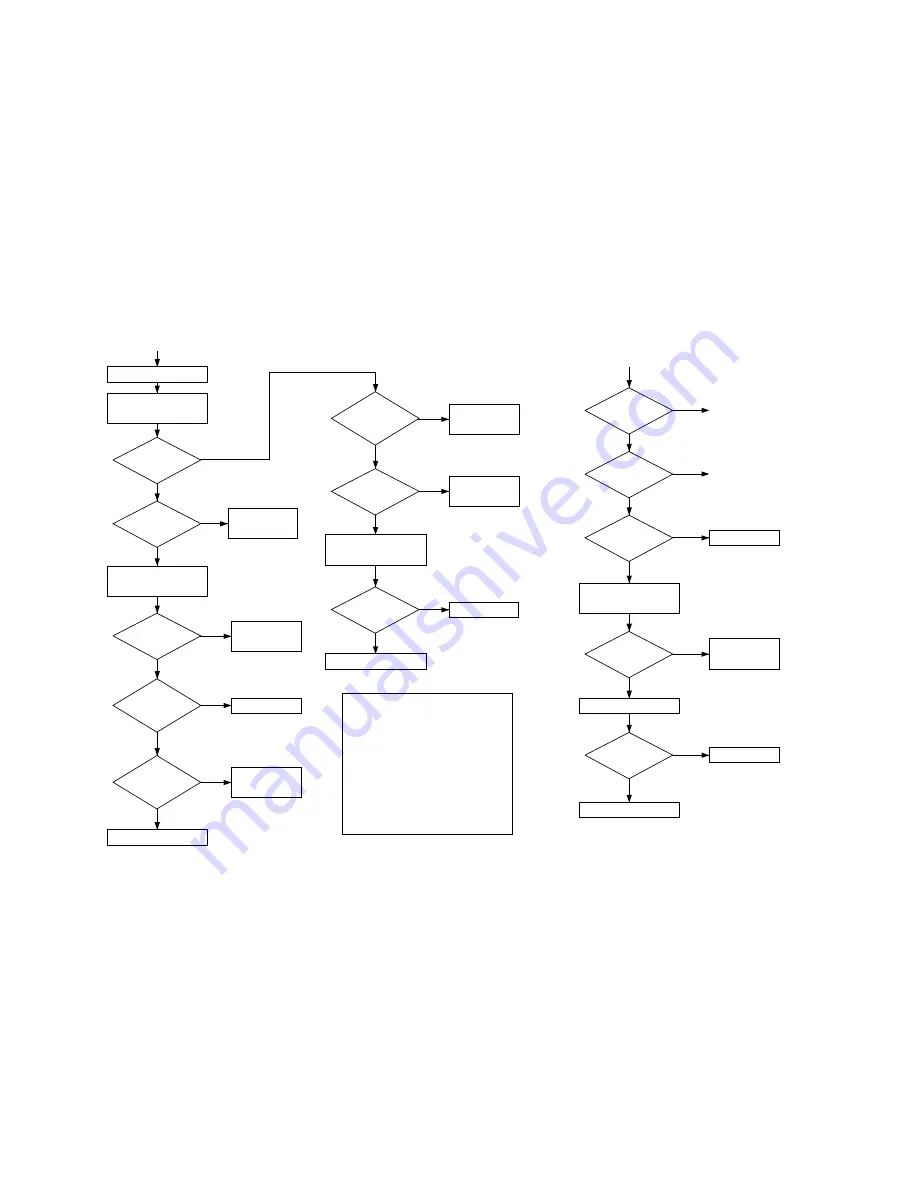

Check the value of DISPLAY>

DENS>DENS-Y, DENS-M, DENS-C,

DENS-K in service mode.

Is the density of

black normal?

Is the value of

DENS-K -20 or lower?

Compare the density of a test print

made of Bk halftone against one

made at time of installation or

replacement of the developer.

Is it more or less the same?

Is the surface of

the black toner concentration

sensor soiled?

Is the test print of Bk

mono halftone uneven?

Replace the Bk developer.

Check the supply of toner

from the hopper.

Go through the check

items for the developing

assembly.

Clean the surface of the

sensor.

Replace the

photosensitive drum and

developer (all colors).

Is the value of

DENS-Y, DENS-M,

DENS-C the specified

value ± 20?

Is it -20 or lower?

Remove the toner concentration

sensor from inside the developing

assembly.

Is the surface of

the sensor soiled?

Replace the developer.

Go through the check

items for the developing

assembly.

Check the supply of

toner from the hopper.

Replace the sensor.

Check Items for the Developing Assembly

1. Is the mechanism used to lock the developing assembly to

the photosensitive drum normal?

2. Is the position of the developing assembly normal?

3. Are the developing assembly butting roll and butting block

free of dirt?

4. Are the developing bias AC and DC outputs normal?

5. Is the developing cylinder coated with an even layer of toner?

Further, is the coating thick enough?

6. Is the position of the electrode of the developing cylinder

normal?

If a fault is found after making the above checks, perform

cleaning or adjustment as necessary.

If fogging or light density still occurs after making all above

checks (1 through 6), replace the developing assembly.

Correcting Fogging

Is fogging noted?

Is fogging noted

for all colors?

Is the primary charging

assembly soiled?

Execute FUNCTION>DPC>DPC

in service mode.

Is the value of

DISPLAY>DPOT>V00-500,

V00-700 normal>?

Check the developing assembly.

Is there a fault?

Replace the photosensitive drum and

developers (all colors).

To [D] of next page.

To [B].

Clean.*

Check the laser shutter,

and adjust the laser

power.

Reference (normal value):

V00-500: 430 to 570

V00-700: 600 to 800

Correct the fault.