CHAPTER 2 STANDARDS AND ADJUSTMENTS

2-10

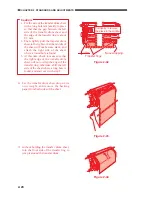

6) Dry wipe the window of the pre-

cleaning sensor, and mount it.

7) Turn on the power switch, and keep

the copier in standby state.

8) Select FUNCTION>INSTALL>

STIR-4 in service mode, and execute

it.

9) Select FUNCTION>SENS-ADJ>

CLN-OFST, and execute it.

10) Record the settings of ADJUST>

SENS-ADJ>CLN-TH, CLN-TMP

on the service label attached behind

the front right cover.

11) Select FUNCTION>INSTALL>

INIT-D in service mode, and execute

it.

c.

If the surface of the photosensitive drum

is soiled, wipe it with a flannel cloth

coated with toner. (Do NOT use paper,

lint-free or otherwise.)

Do not use solvent when cleaning it. Do

not touch its surface.

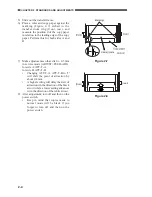

3

Adjusting the Position of the

Photosensitive Drum Fixing

Shaft

Slide the photosensitive drum frame unit

about 5 cm out of the copier, and then slide it

back in. If the movement is not smooth, adjust

the position of the photosensitive drum fixing

shaft using the drum shaft positioning tool

(FY9-3045).

This adjustment, however, need not be

made if the images are free of color

displacement, blurring, and faults at intervals

and, moreover, the discrepancy between the

photosensitive drum fixing shaft and the hole

of the photosensitive drum flange is about 1

mm.

1) Slide out the photosensitive drum unit

from the copier.

2) Remove the six screws [1], and detach the

photosensitive drum butting blocks [2]

(front, back); then, detach the

photosensitive drum [3] from the

photosensitive drum frame unit [4].

3) Slide the photosensitive drum frame unit

into the copier, and secure it in place with

three screws.

4) Secure the drum motor assembly [5] to the

copier temporarily with seven screws [6].

Figure 2-18

Figure 2-19

[2]

[1]

[3]

[4]

[1]

[2]

[6]

[6]

[6]

[6]

[5]

[6]