CHAPTER 9 EXTERNALS / AUXILIARY MECHANISMS

9-18

COPYRIGHT © 1999 CANON INC. CANON CLC1120/1130/1150 REV.0 MAR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

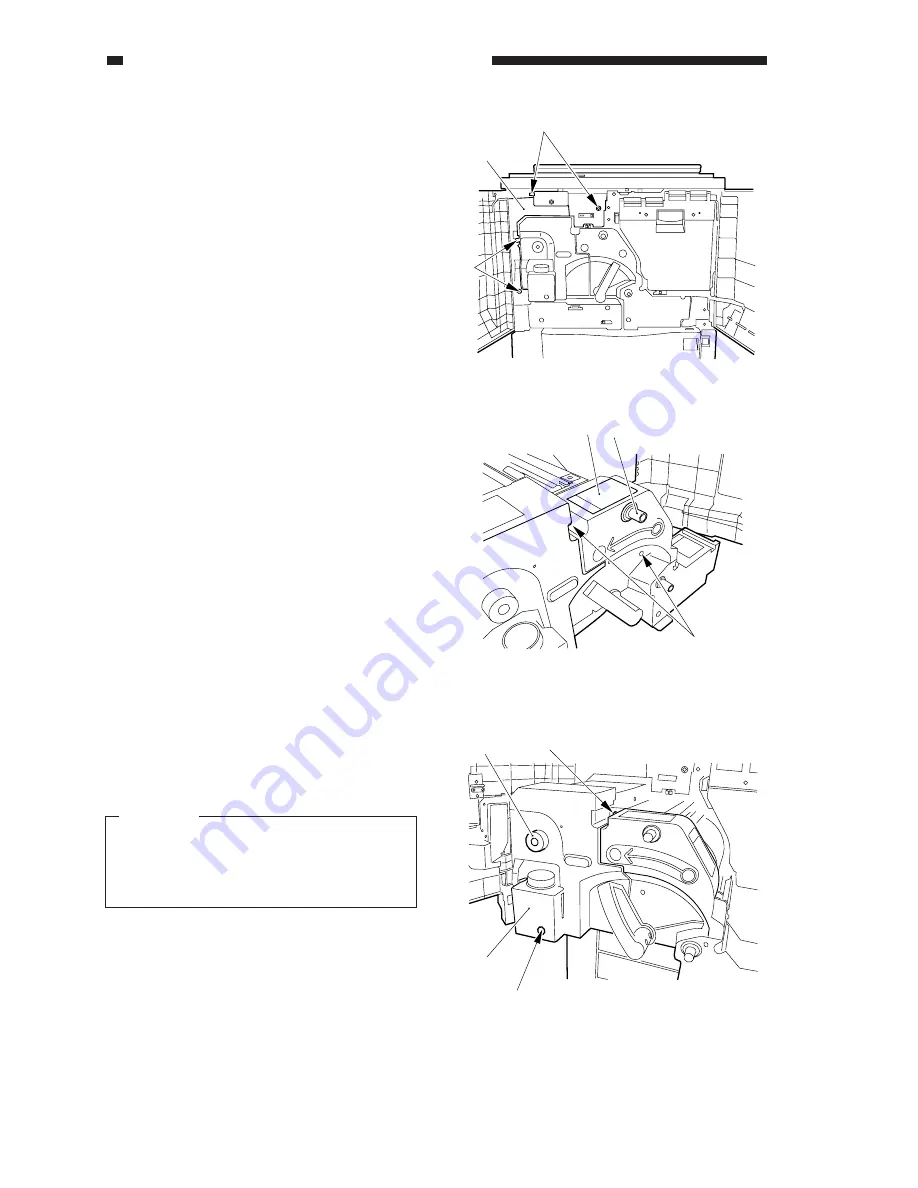

3. Left Inside Cover

1) Remove the four screws [1].

2) Slide out the transfer drum frame, and

remove the left inside cover [2].

Figure 9-703

4. Transfer Drum Frame Cover

1) Remove the transfer drum knob [1].

2) Remove the two screws [2], and detach

the transfer drum frame cover [3].

figure 9-704

5. Fixing Assembly Cover

1) Remove the screw, and detach the fixing

knob [1].

2) Remove the two screws [2], and detach

the fixing assembly cover [3].

Caution:

When mounting the fixing assembly

cover, be sure that the hook at the bottom

of the cover is securely fitted into the

hole in the transfer drum frame.

Figure 9-705

[2]

[1]

[1]

[2]

[1]

[3]

[2]

[3]

[1]

[2]

Summary of Contents for CLC 1120

Page 6: ......

Page 20: ......

Page 22: ......

Page 48: ......

Page 94: ......

Page 96: ......

Page 114: ......

Page 134: ......

Page 136: ......

Page 152: ......

Page 242: ......

Page 346: ......

Page 374: ......

Page 376: ......

Page 412: ......

Page 452: ......

Page 454: ......

Page 517: ......

Page 881: ......

Page 893: ......

Page 895: ......

Page 899: ......