CHAPTER 1 GENERAL DESCRIPTION

1-12

COPYRIGHT © 2001 CANON INC.

2000 2000 2000 2000

CANON CLC5000 REV.0 JAN. 2001

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

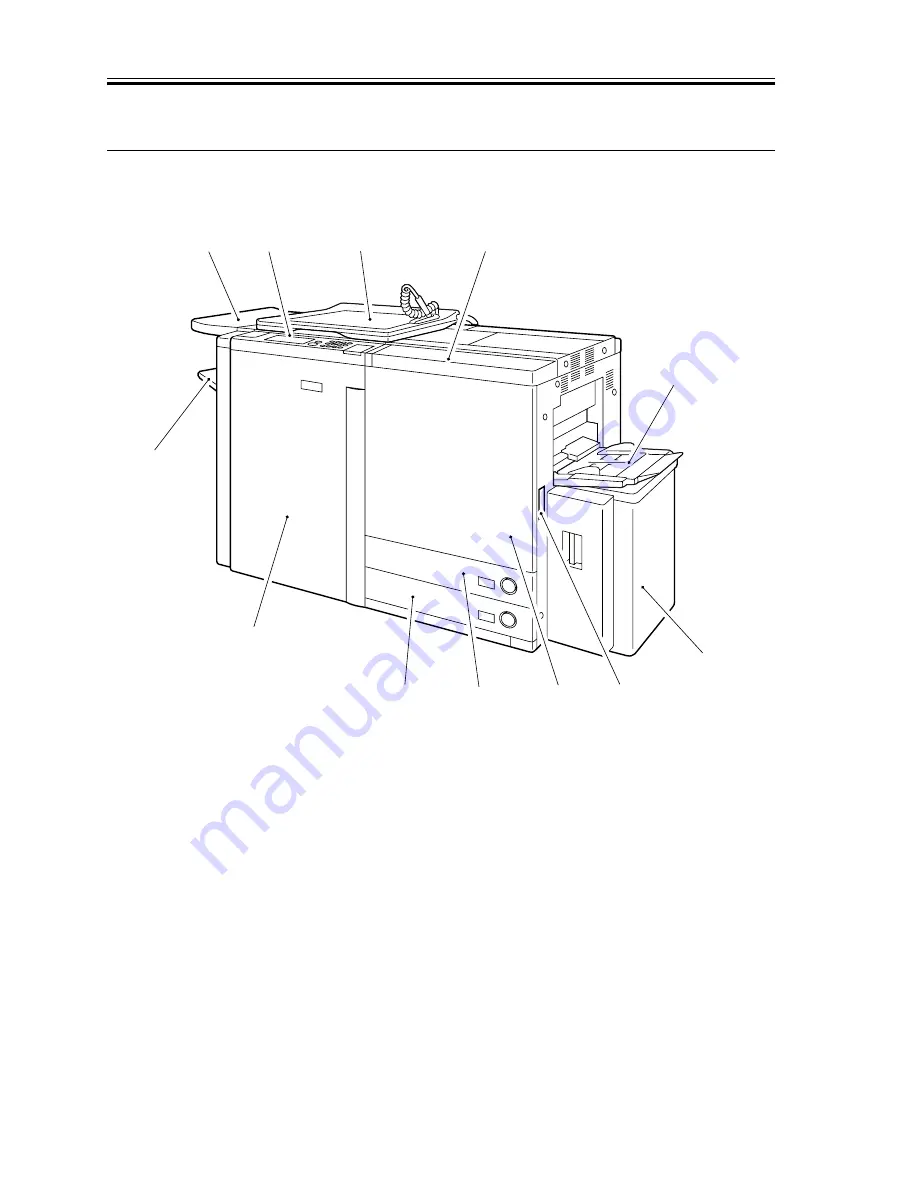

3 Names of Parts

3.1 External View

[1] Copyboard

[7] Control key/power switch

[2] Control panel

[8] Right front cover

[3] Editor (accessory)

[9] Cassette 1

[4] Hopper lid (toner supply mouth)

[10] Cassette 2

[5] Multifeeder assembly

[11] Left front cover

[6] Paper deck (accessory)

[12] Delivery tray

F01-301-01

Summary of Contents for CLC 5000

Page 7: ...Main Body Accessory COPYRIGHT 2001 CANON INC 2000 2000 20000 CANON CLC5000 REV 0 JAN 2001 ...

Page 574: ...COPYRIGHT 2001 CANON INC 2000 2000 2000 2000 CANON CLC5000 REV 0 JAN 2001 APPENDIX ...

Page 578: ...COPYRIGHT 2001 CANON INC 2000 CANON CLC5000 REV 0 JAN 2001 A 4 Blank page ...

Page 587: ...Service Mode COPYRIGHT 2001 CANON INC 2000 CANON CLC5000 REV 0 JAN 2001 ...

Page 725: ...Error Code COPYRIGHT 2001CANONINC 2000CANONCLC5000REV 0JAN 2001 ...

Page 727: ...COPYRIGHT 2001 CANON INC 2000 CANON CLC5000 REV 0 JAN 2001 ii CONTENTS Blank page ...