Chapter 9

9-8

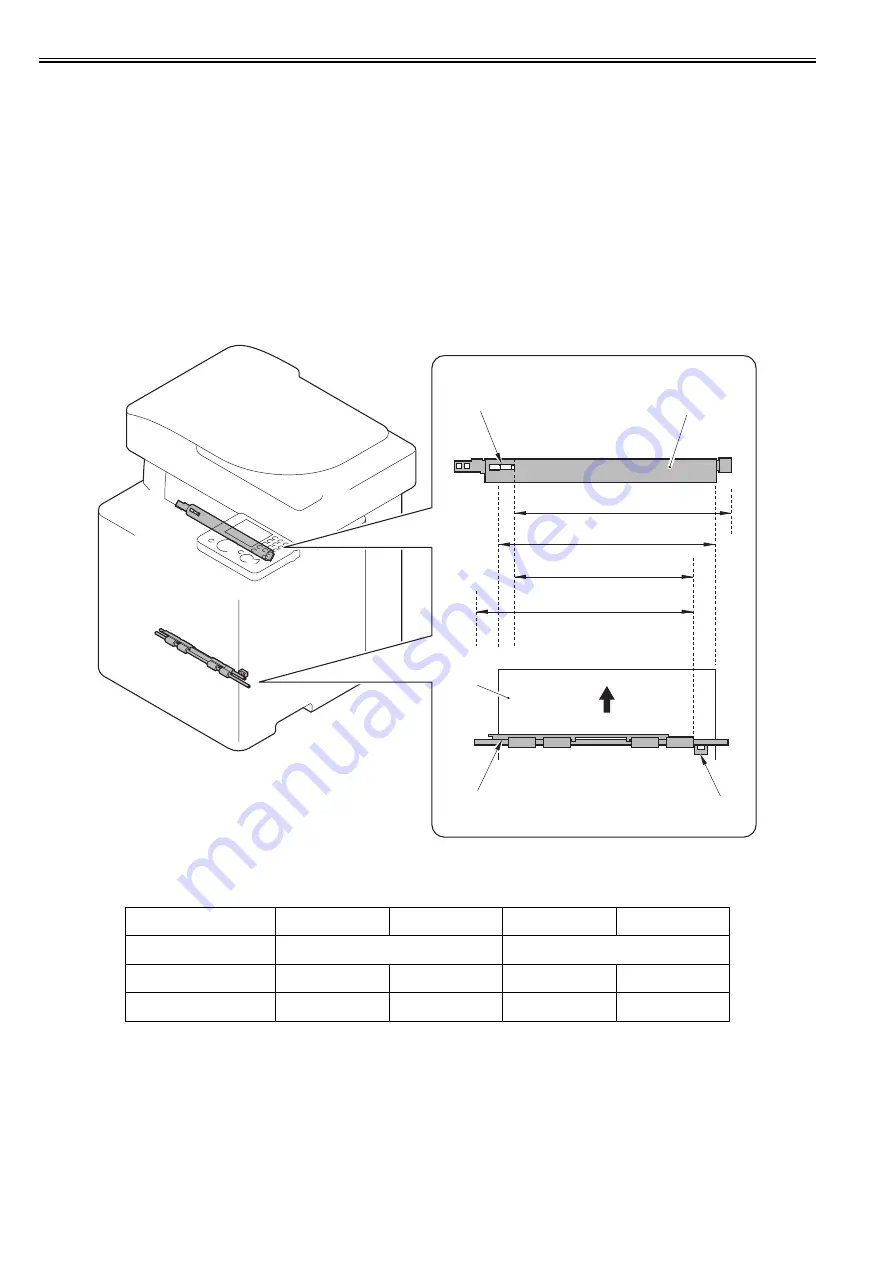

9.2.4 Throughput-down Control

0020-0387

imageRUNNER C1022 / imageRUNNER C1022i

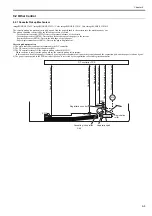

The machine prevents an abnormal temperature increase at the edge of the fixing sleeve by increasing an interval between sheets while keeping the paper feeding

speed as needed.

Control of the fixing assembly is performed to keep the temperature of the fixing heater higher than the target temperature while the paper is transported so that the

target fixing temperature is maintained (print temperature control).

When the paper is displaced to one side, the paper does not pass a certain area at the edge of the fixing sleeve. In this area, no heat is transported to the paper, causing

temperature increase every time the paper passes the area.

Even when the temperature of the fixing heater is set lower than the target temperature between sheets (control of temperature between sheets), the effect of tem-

perature increase is reinforced when continuous printing is performed, and therefore an abnormal temperature increase occurs at the edge of the fixing sleeve.

To prevent an abnormal temperature increase, the machine increases an interval between sheets when the paper is fed displaced to one side, and promotes a tem-

perature decrease between sheets.

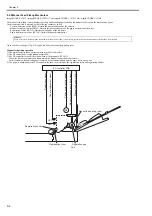

The machine uses the paper displacement sensor (SR714) located at the right side of the registration shutter in order to detect the paper displacement.

The sensor detects whether the paper width is smaller than the specified paper width or whether the paper is displaced to the left side of the feed path.

Whether the paper width is smaller than the specified paper width or whether the paper is displaced to the right side of the feed path can be detected by the fixing

sub thermistor (TH2) because an abnormal temperature increase occurs at the left edge of the fixing sleeve.

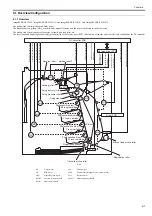

F-9-8

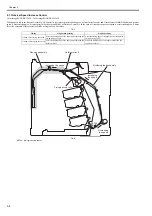

Different throughput-down controls are executed depending on the result of detection performed by the paper displacement sensor and fixing sub thermistor.

T-9-3

*1: For the universal-size paper or the paper of which width is smaller than A4-size, an interval between sheets is changed step by step according to the

temperature detected by the fixing sub thermistor.

*2: Although throughput-down control is not performed, a restriction is applied to the power supplied to the fixing heater.

Paper displacement

The paper is displaced

to the left side

The paper width is

smaller *1

The paper is not

displaced

The paper is displaced

to the right side

Paper displacement detection

sensor (SR714)

No paper detection is performed

Paper detection is performed

Fixing sub thermistor (TH2)

Lower than the

specified temperature

Higher than the

specified temperature

Lower than the

specified temperature

Higher than the

specified temperature

Throughput-down control

Instantly executed (the

lowest value)

Executed step by step

No throughput-down

control performed

No throughput-down

control performed *2

The paper is displaced to the right.

The paper is not displaced.

The paper is displaced to the left.

The paper width is smaller.

Registration shutter

Paper

TH2

Fixing sleeve

SR714

Summary of Contents for Color imageRUNNER C1022

Page 2: ......

Page 6: ......

Page 19: ...Chapter 1 Introduction ...

Page 20: ......

Page 93: ...Chapter 2 Installation ...

Page 94: ......

Page 96: ......

Page 111: ...Chapter 3 Basic Operation ...

Page 112: ......

Page 114: ......

Page 119: ...Chapter 4 Main Controller ...

Page 120: ......

Page 122: ......

Page 135: ...Chapter 5 Original Exposure System ...

Page 136: ......

Page 138: ......

Page 151: ...Chapter 6 Original Feeding System ...

Page 152: ......

Page 154: ......

Page 170: ......

Page 171: ...Chapter 7 Laser Exposure ...

Page 172: ......

Page 174: ......

Page 184: ......

Page 185: ...Chapter 8 Image Formation ...

Page 186: ......

Page 188: ......

Page 222: ......

Page 223: ...Chapter 9 Pickup and Feed System ...

Page 224: ......

Page 259: ...Chapter 10 Fixing System ...

Page 260: ......

Page 262: ......

Page 268: ...Chapter 10 10 6 ...

Page 279: ...Chapter 11 External and Controls ...

Page 280: ......

Page 311: ...Chapter 12 e Maintenance imageWARE Remote ...

Page 312: ......

Page 314: ......

Page 323: ...Chapter 12 12 9 F 12 27 ...

Page 349: ...Chapter 13 Maintenance and Inspection ...

Page 350: ......

Page 352: ......

Page 354: ......

Page 355: ...Chapter 14 Measurement and Adjustments ...

Page 356: ......

Page 358: ......

Page 361: ...Chapter 15 Correcting Faulty Images ...

Page 362: ......

Page 364: ......

Page 385: ...Chapter 16 Error Code ...

Page 386: ......

Page 388: ......

Page 399: ...Chapter 16 16 11 ...

Page 400: ......

Page 401: ...Chapter 17 Special Management Mode ...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 17 17 7 ...

Page 412: ......

Page 413: ...Chapter 18 Service Mode ...

Page 414: ......

Page 492: ......

Page 493: ...Chapter 19 Upgrading ...

Page 494: ......

Page 496: ......

Page 500: ...Chapter 19 19 4 3 Click Next F 19 4 4 Select a USB connected device and click Next F 19 5 ...

Page 501: ...Chapter 19 19 5 5 Click Start F 19 6 6 Click Yes F 19 7 Download will be started F 19 8 ...

Page 504: ...Chapter 19 19 8 4 Select a USB connected device and click Next F 19 12 5 Click Start F 19 13 ...

Page 506: ...Chapter 19 19 10 ...

Page 507: ...Chapter 20 Service Tools ...

Page 508: ......

Page 510: ......

Page 514: ......

Page 515: ...Appendix ...

Page 516: ......

Page 532: ......

Page 533: ...Oct 29 2010 ...

Page 534: ......