2

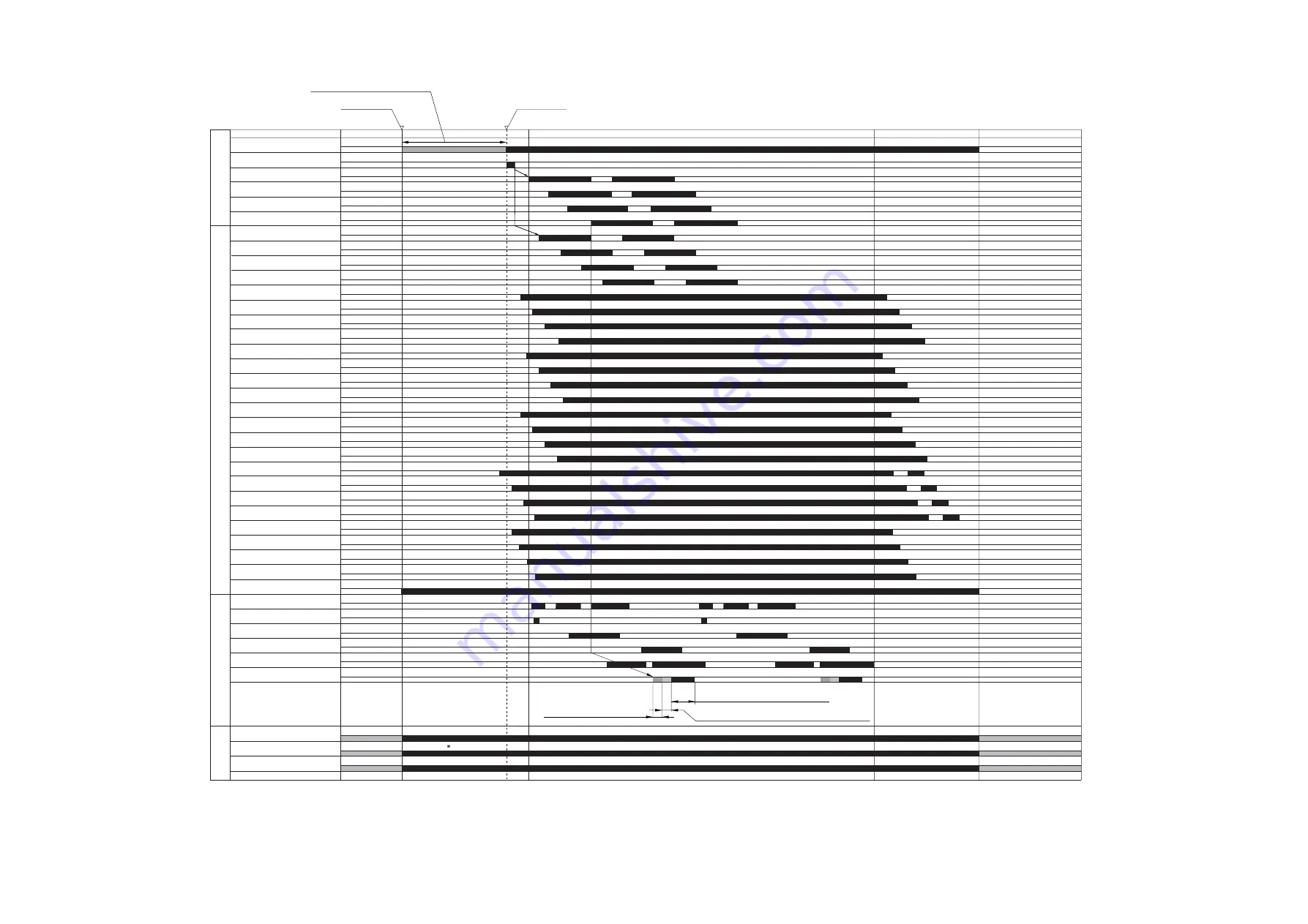

Sequence of Operations (printer unit)

Full color, Cassette 1, A4 Single-sided (2 prints, continuous)

F-1-2

PSTBY

PSTBY

PINTR

LSTR

Printer unit

Image f

or

mation

Laser e

xposure

Pic

kup/f

eeding

Fixing

*1: iRC5180,iRC4580/3880(230V)only

Used to stabilize the rotation (3.5 sec)

Ready for image

formation

Start key ON

Deceleration control: slows down to the front of the secondary

transfer roller to synchronize transfer timing.

Acceleration control:

accelerates before pulling on

the leading edge of paper.

Constant control: synchronizes transfer timing

and then with process speed.

1

IH heater (H1)

Pressure heater (H2)

Toner stirring motor Y

(M20)

Toner stirring motor M

(M21)

Toner stirring motor C

(M22)

Toner stirring motor Bk

(M23)

Development motor Y

(M12)

Development motor M

(M13)

Development motor C

(M14)

Development motor Bk

(M15)

Developing bias AC (Y)

Developing bias AC (M)

Developing bias AC (C)

Development basis AC

(Bk)

Developing bias DC (Y)

Developing bias DC (M)

Developing bias DC (C)

Developing basis DC

(Bk)

Charging roller AC (Y)

Charging roller AC (M)

Charging roller AC (C)

Charging roller AC (Bk)

Charging roller DC (Y)

Charging roller DC (M)

Charging roller DC (C)

Charging roller DC (Bk)

Cassette 1 pickup motor

(M6)

Cassette 1 pickup

solenoid (SL3)

Cassette 1 retry paper

sensor (PS16)

Registration sensor

(PS26)

Laser Y ON

Laser M ON

Laser C ON

Laser Bk ON

Pre-registration motor

(M8)

Registration motor

(M9)

Drum ITB motor (M1)

Fixing motor (M24)

ITOP signal

Polygon motor (Y,M,C,Bk)

Summary of Contents for Color imageRUNNER C5180 Series

Page 22: ...Chapter 1 INTRODUCTION...

Page 64: ...Chapter 2 INSTALLATION...

Page 110: ...Chapter 3 BASIC OPERATION...

Page 119: ...Chapter 4 BASIC OPERATIONS AS A PRINTER...

Page 129: ...Chapter 5 MAIN CONTROLLER...

Page 138: ...Chapter 5 5 8 F 5 8 CPU HDD ROM access to the program at time of execution...

Page 165: ...Chapter 6 ORIGINAL EXPOSURE SYSTEM...

Page 209: ...Chapter 7 IMAGE PROCESSING SYSTEM...

Page 212: ...Chapter LASER EXPOSURE 8...

Page 239: ...Chapter 9 IMAGE FORMATION...

Page 324: ...Chapter 10 PICKUP FEEDING SYSTEM...

Page 435: ...Chapter 11 FIXING SYSTEM...

Page 460: ...Chapter 11 11 23 F 11 13 SEN3 SEN2 SEN1 SEN2 SEN3 SEN1 SEN2 SEN3 SEN1...

Page 491: ...Chapter 12 EXTERNALS CONTROLS...

Page 498: ...Chapter 12 12 5 F 12 2 FM1 FM7 FM9 FM2 FM13 FM14 FM12 FM11 FM10 FM5 FM3 FM4 FM8 FM6...

Page 512: ...Chapter 12 12 19 2 Remove the check mark from SNMP Status Enabled F 12 10...

Page 553: ...Chapter 13 MEAP...

Page 557: ...Chapter 14 RDS...

Page 569: ...Chapter 15 MAINTENANCE INSPECTION...

Page 578: ...Chapter 16 STANDARDS ADJUSTMENTS...

Page 597: ...Chapter 17 CORRECTING FAULTY IMAGES...

Page 612: ...Chapter 17 17 14 F 17 7 PLG1 ELCB1 SP1 H4 H3 H2 H1 H1 H2 LA1...

Page 617: ...Chapter 18 SELF DIAGNOSIS...

Page 644: ...Chapter 19 SERVICE MODE...

Page 778: ...Chapter 20 UPGRADING...

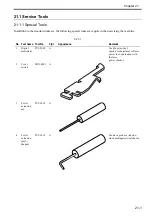

Page 823: ...Chapter 21 SERVICE TOOLS...

Page 828: ...APPENDIX...

Page 851: ......