Chapter 11

11-16

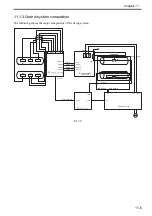

T-11-17

2. Temperature rise control at end of Pressure heater *1

If either the pressure sub-thermistor 1 (TH5) or the pressure sub-thermistor 2 (TH6) detects 215 deg C or higher,

the pressure heater is turned to off.

If both the pressure sub-thermistor 1 (TH5) and the pressure sub-thermistor 2 (TH6) are less than 215 deg C, the

temperature in print mode is controlled.

*1: Only for iR C5180 and iR C4580/4080 (230 V)

T-11-18

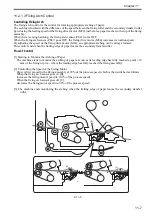

11.2.2.7 Measurements against heating of fixing tension roller

Objective

- To detect the high-temperature error by bringing fixing sub thermistor into contact with tension roller if the

fixing belt becomes torn.

- To detect high-temperature error by fixing sub thermistor 2 as fixing tension roller (metal) temperature

becomes higher than the inside of the belt at the time of start-up.

These operations against the heating of tension roller are conducted during warm-up, recovery mode, and stand-

by.

[1] Step 1

The system lowers the electric power capacity on the IH heater when either of sub thermistor 1 (TH2) or sub

thermistor 2 (TH3) detects the temperature higher than 215 deg C. (electric capacity *1 in the print mode ->

700W)

The system recovers the electric capacity when both of sub thermistor 1 (TH2) or sub thermistor 2 (TH3) detect

the temperature lower than 215 deg C. (700W -> electric capacity *1 in the print mode)

[2] Step2

The system sets the electric power capacity on the IH heater 0W when either of sub thermistor 1 (TH2) or sub

thermistor 2 (TH3) detects the temperature higher than 220 deg C.

The system goes to the step [1] when both of sub thermistor 1 (TH2) or sub thermistor 2 (TH3) detect the

temperature lower than 215 deg C.

T-11-19

IH Power at normal

IH Power Upper limit /

Temperature 1 to change

IH Power Upper limit /

Temperature 2 to change

IH Power Upper limit

1100 W

500 W

0 W

Fixing sub-thermistor 1/2 Less than 215 deg C 215 deg C

220 deg C

Pressure heater forced off temperature

Pressure sub-thermistor 1/2

215 deg C

temperature to change IH

electric capacity 1

temperature to change IH

electric capacity 2

IH electric capacity

700 W

0 W

Fixing sub-thermistor 1/2

215 deg C

220 deg C

Summary of Contents for Color imageRUNNER C5180 Series

Page 22: ...Chapter 1 INTRODUCTION...

Page 64: ...Chapter 2 INSTALLATION...

Page 110: ...Chapter 3 BASIC OPERATION...

Page 119: ...Chapter 4 BASIC OPERATIONS AS A PRINTER...

Page 129: ...Chapter 5 MAIN CONTROLLER...

Page 138: ...Chapter 5 5 8 F 5 8 CPU HDD ROM access to the program at time of execution...

Page 165: ...Chapter 6 ORIGINAL EXPOSURE SYSTEM...

Page 209: ...Chapter 7 IMAGE PROCESSING SYSTEM...

Page 212: ...Chapter LASER EXPOSURE 8...

Page 239: ...Chapter 9 IMAGE FORMATION...

Page 324: ...Chapter 10 PICKUP FEEDING SYSTEM...

Page 435: ...Chapter 11 FIXING SYSTEM...

Page 460: ...Chapter 11 11 23 F 11 13 SEN3 SEN2 SEN1 SEN2 SEN3 SEN1 SEN2 SEN3 SEN1...

Page 491: ...Chapter 12 EXTERNALS CONTROLS...

Page 498: ...Chapter 12 12 5 F 12 2 FM1 FM7 FM9 FM2 FM13 FM14 FM12 FM11 FM10 FM5 FM3 FM4 FM8 FM6...

Page 512: ...Chapter 12 12 19 2 Remove the check mark from SNMP Status Enabled F 12 10...

Page 553: ...Chapter 13 MEAP...

Page 557: ...Chapter 14 RDS...

Page 569: ...Chapter 15 MAINTENANCE INSPECTION...

Page 578: ...Chapter 16 STANDARDS ADJUSTMENTS...

Page 597: ...Chapter 17 CORRECTING FAULTY IMAGES...

Page 612: ...Chapter 17 17 14 F 17 7 PLG1 ELCB1 SP1 H4 H3 H2 H1 H1 H2 LA1...

Page 617: ...Chapter 18 SELF DIAGNOSIS...

Page 644: ...Chapter 19 SERVICE MODE...

Page 778: ...Chapter 20 UPGRADING...

Page 823: ...Chapter 21 SERVICE TOOLS...

Page 828: ...APPENDIX...

Page 851: ......