COPYRIGHT © 1999 CANON INC.

CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

5-29

CHAPTER 5 TROUBLESHOOTING

Item

Setting

Description

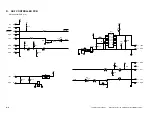

Original tray width

adjustment

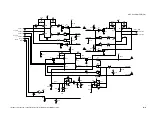

Registration

position adjustment

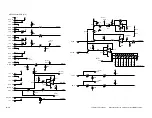

Duplexing

registration

Adjustment

(pickup delivery)

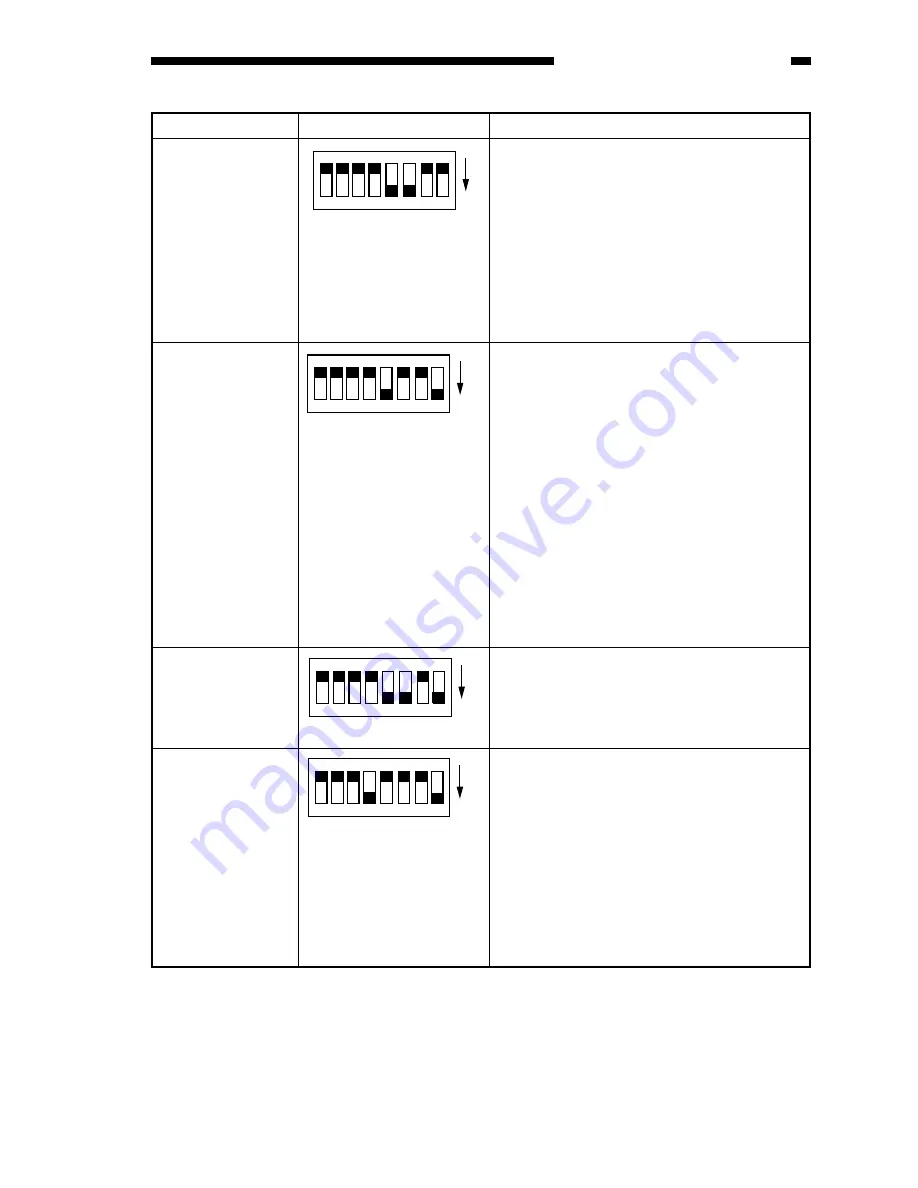

Shift bits 3 and 4 of the DIP switch (DSW1)

to ON. Adjust the original tray to A4 (for A/B

configuration) or LTR (for inch

configuration); then, press the push switch

(SW1).

Adjust the original tray to A4R (for A/B

configuration) or LTRR (for inch

configuration); and, press the push switch

once gain.

Lastly, press the push switch (SW1) once

again, and shift all bits to OFF.

Shift bits 1 and 4 of the DIP switch (DSW1)

to ON, and press the push switch (SW1);

then, close the ADF.

Place one original on the original tray. (In

about 3 sec, the original will be moved to the

copyboard glass and stopped.)

Open the ADF, and check the position of the

original. If it is to the left in relation to the

image leading edge, shift bit 5 of the DIP

switch (DSW1) to ON; if it is to the right, shift

bit 6 to ON.

Press the push switch (SW1) as many times as

necessary. A single press causes a shift of

0.34 mm.

The original will be discharged automatically

when the ADF is closed. After adjustment,

shift all bits to OFF.

Shift bits 1, 3, and 4 of the DIP switch

(DSW1) to ON, and press the push switch

(SW1); then, close the ADF.

Perform the steps for "registration

adjustment"; at the end, shift all bits to OFF.

Use this item if you want to use the ADF on

its own for pickup and delivery.

Shift bits 1 and 5 of the DIP switch (DSW1)

to ON, and press the push switch (SW1);

then, close the ADF.

Place an original on the original tray. In about

3 sec, the original will be moved to the

copyboard glass and stopped.

The original will be discharged automatically

when the ADF is opened and then closed.

When you have checked the operation, be

sure to shift all bits to OFF.

O

F

F

1

2

3

4

5

6

7

8

ON

O

F

F

1

2

3

4

5

6

7

8

ON

O

F

F

1

2

3

4

5

6

7

8

ON

O

F

F

1

2

3

4

5

6

7

8

ON