COPYRIGHT © 1999 CANON INC.

CANON DADF-B1 REV.0 APR. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

5-3

CHAPTER 5 TROUBLESHOOTING

3

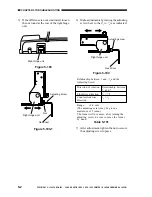

Adjusting the Position of the

Reversal Delivery Flapper

If a double-sided original tends to jam or

fold into a Z in the duplexing feeding

assembly, adjust the position of the reversal

delivery flapper as follows:

1) Remove the four mounting screws, and

detach the front cover. (See A. "External

Covers" under I. "Basic Construction.")

2) Open the reversal delivery unit cover [1],

and loosen the screw [2] shown in the

figure.

Figure 5-105

3) Open the ADF slowly, and turn the

reversal delivery roller [3]

counterclockwise in the direction of [A]

(working from where the reversal delivery

unit cover was) so that the reversal delivery

flapper [4] is as shown .

Figure 5-106

4) If is not as indicated, turn the adjusting

screw [5] to adjust the position of the

reversal delivery flapper.

If it is too narrow, turn the adjusting screw

clockwise; if too wide, on the other hand,

turn it counterclockwise.

Standards: = 0.8 to 1.3 mm

(THICKNESS GAUGE)

If is not as indicated, the following

symptoms tend to occur; be sure to make

adjustments so that it is as indicated:

·

If it is less than 0.8,

double-sided originals will tend to move

askew.

·

If it is more than 1.3,

originals with a bent leading edge

(downward) tend to get hooked on the

reversal inlet assembly.

5) Tighten the screw [2] of the reversal

delivery unit, and close the reversal

delivery unit cover [1].

6) Mount the front cover.

[1]

[2]

0.8 to 1.3mm

[1]

[3]

[4]

[A]

[5]

Figure 5-106-1