4

4

4-234

4-234

Disassembly/Assembly > Controller System > Removing the Main Motor (MF4720w/MF4712/MF4710) > Procedure

Disassembly/Assembly > Controller System > Removing the Main Motor (MF4720w/MF4712/MF4710) > Procedure

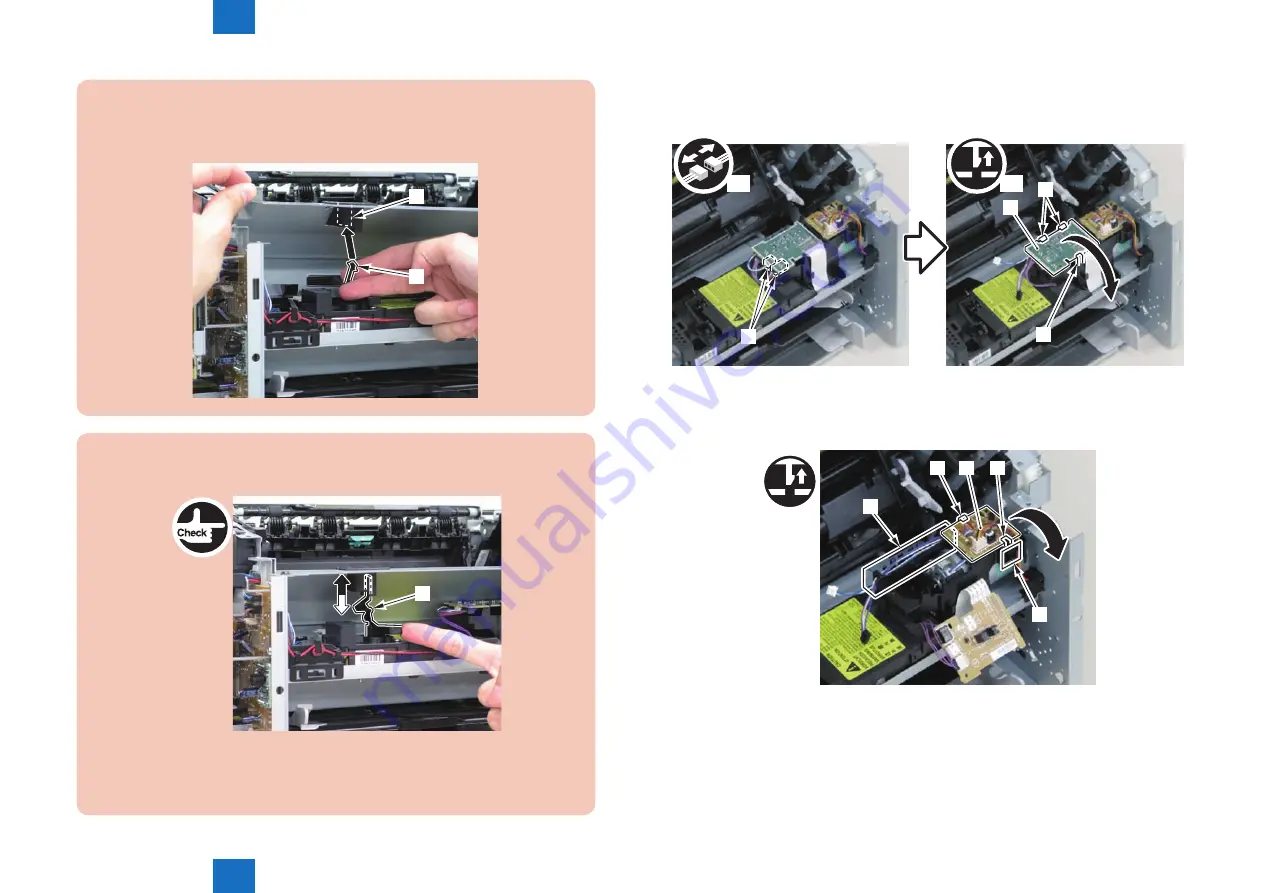

Caution:

When mounting the scanner cover, pass the shutter open/close lever [1] through the

hole [A] in the scanner cover.

[1]

[A]

F-4-617

Caution:

Ensure that the shutter open/close lever [1] can move vertically.

[1]

F-4-618

2)Disconnect the connectors[1], and remove the motor driver PCB[2]

• 2 claws[3]

• 1 hook[4]

[4]

[2]

x2

[3]

x2

[1]

3)Free the harness from the harness guide[A] and [B], and remove the duplex relay PCB[1]

• 1 claw[2]

• 1 hook[3]

[A]

[2] [1]

[B]

[3]

F-4-619

F-4-620

Summary of Contents for FAXPHONE L190

Page 470: ...5 5 Adjustment Adjustment Mechanical Adjustment ...

Page 480: ...7 7 Error Codes Error Codes Overview Error Codes ...

Page 484: ...8 8 Service Mode Service Mode Overview COPIER FEEDER FAX TESTMODE ...

Page 501: ... Service Tools Solvent Oil List General Circuit Diagram General Timing Chart Appendix ...