2

2

2-11

2-11

Technology > Controls (Reader)

Technology > Controls (Reader)

• Between sheets

The machine does not move CCD.

It reads the original using the position determined at the end or start of a job; however,

if the presence of dust is still detected at the position, the machine will execute image

correction.

0.5mm

0.5mm

A B C

Platen roller

Stream

reading glass

Service Mode

(Lv1) COPIER > OPTION > IMG-RDR > DFDST-L1

(used to adjust the dust detection level between sheets)

(Lv1) COPIER > OPTION > IMG-RDR > DFDST-L2

(used to adjust the dust detection level at the end of a job)

F-2-19

■

Image Processing

●

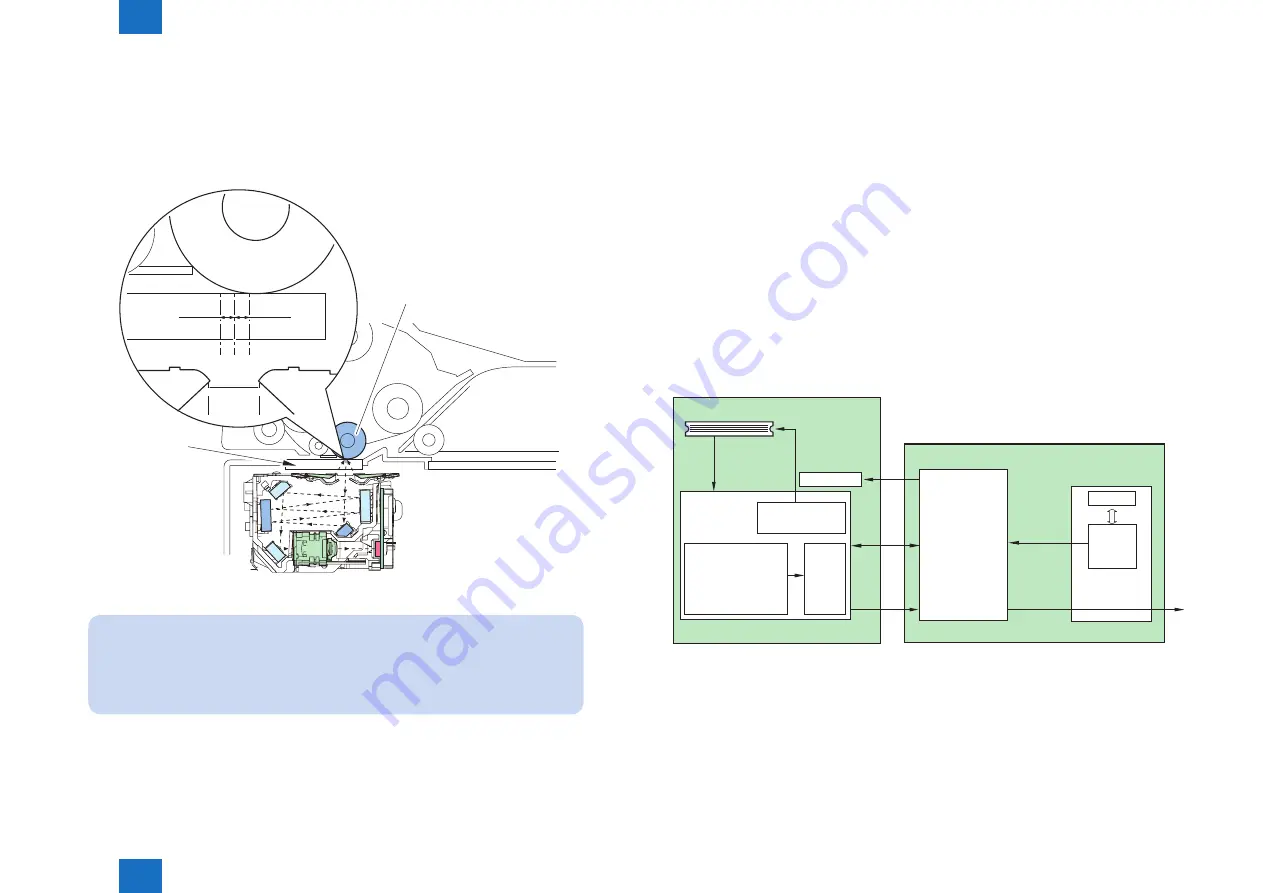

Overview

The functions of image processing system’s PCB are described below.

• Main controller PCB

Shading correction (executed per each job),

• CCD PCB

CCD drive, analog image process, A/D conversion, A/D

conversion

The machine uses the main controller PCB to process images for every single image line.

Specific functions are as follows.

a. Main controller PCB

• Shading correction

• Color offset correction in sub scanning

b. CCD PCB (inside CCD unit)

• CCD drive

• CCD output gain correction, offset correction

CCD (4lines)

Analog image

signal

Analog image

process

- gain correction

- offset correction

A/D

conversion

CCD/AP PCB

Gain

correction

data

Digital

image

signal

Reader controller PCB

CCD PCB

SRAM

CPU

ASIC

EEP-ROM

CCD drive

control

Shading

correction

Color offset

correction

in sub scanning

F-2-20