Chapter 7

7-3

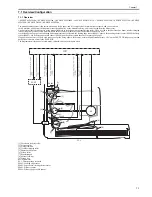

[7] Separation pad

[8] Manual feed tray

[9] Pickup tray

M1: Main motor

SL1: Cassette pickup solenoid

PS801: Leading edge sensor

PS802: Paper width/cartridge detect sensor

PS803: Delivery sensor

PS804: Delivery paper width sensor

7.3 Detection Jams

7.3.1 Jam Detection Outline

7.3.1.1 Overview

0020-2698

i-SENSYS MF4300dn / i-SENSYS MF4350d / i-SENSYS MF4380dn / i-SENSYS MF4310/4318 / i-SENSYS MF4320d / i-SENSYS MF4330d / i-SENSYS

MF4340d / i-SENSYS D450d / i-SENSYS MF4370dn

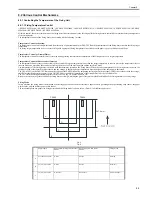

The machine has the following paper sensors to detect the presence/absence of paper at the time of startup, opening the door, or feeding a paper, as well as to detect

whether a paper is fed normally.

1. Leading edge sensor (PS801)

2. Paper width/cartridge detect sensor (PS802)

3. Delivery sensor (PS803)

4. Delivery paper width sensor (PS804)

In terms of jam, it is judged by whether a paper is at the sensor assembly at the time of the check time memorized in the CPU beforehand. If the CPU judges as the

occurrence of jam, the printing operation is aborted and at the same time, it notifies it to the SCNT PCB.

7.3.2 Delay Jams

7.3.2.1 Pickup Delay Jam

0020-2699

i-SENSYS MF4300dn / i-SENSYS MF4350d / i-SENSYS MF4380dn / i-SENSYS MF4310/4318 / i-SENSYS MF4320d / i-SENSYS MF4330d / i-SENSYS

MF4340d / i-SENSYS D450d / i-SENSYS MF4370dn

In order to prevent the pickup delay jam due to the pickup failure, the machine executes the retry control that performs the pickup operation up to twice.

In the second pickup operation, if the leading edge sensor (PS801) cannot detect the leading edge of paper within about 1.45 sec since the Cassette pickup solenoid

(SL1) turns ON, the DCNT PCB judges as the pickup delay jam.

7.3.2.2 Delivery Delay Jam

0020-2700

i-SENSYS MF4300dn / i-SENSYS MF4350d / i-SENSYS MF4380dn / i-SENSYS MF4310/4318 / i-SENSYS MF4320d / i-SENSYS MF4330d / i-SENSYS

MF4340d / i-SENSYS D450d / i-SENSYS MF4370dn

If the delivery sensor (PS803) cannot detect the leading edge of paper after passing about 1.65 sec from the detection of the leading edge of paper with the leading

edge sensor (PS801), the DCNT PCB judges as the delivery delay jam.

7.3.3 Stationary Jams

7.3.3.1 Pickup Stationary Jam

0020-2701

i-SENSYS MF4300dn / i-SENSYS MF4350d / i-SENSYS MF4380dn / i-SENSYS MF4310/4318 / i-SENSYS MF4320d / i-SENSYS MF4330d / i-SENSYS

MF4340d / i-SENSYS D450d / i-SENSYS MF4370dn

If the trailing edge of paper cannot be detected after passing about 5.4 sec since the leading edge sensor (PS801) detects the leading edge of paper, the DCNT PCB

judges as the pickup stationary jam.

7.3.3.2 Delivery Stationary Jam

0020-2702

i-SENSYS MF4300dn / i-SENSYS MF4350d / i-SENSYS MF4380dn / i-SENSYS MF4310/4318 / i-SENSYS MF4320d / i-SENSYS MF4330d / i-SENSYS

MF4340d / i-SENSYS D450d / i-SENSYS MF4370dn

If the delivery sensor (PS803) cannot detect the leading edge of paper within about 1.48 sec after the leading edge sensor (PS801) detects the trailing edge of paper,

the DCNT PCB judges as the delivery stationary jam.

7.3.4 Other Jams

7.3.4.1 Door Open Jam

0020-2704

i-SENSYS MF4300dn / i-SENSYS MF4350d / i-SENSYS MF4380dn / i-SENSYS MF4310/4318 / i-SENSYS MF4320d / i-SENSYS MF4330d / i-SENSYS

MF4340d / i-SENSYS D450d / i-SENSYS MF4370dn

If the leading edge sensor (PS801) or the delivery sensor (PS803) detects a paper when door open is detected, the DCNT PCB judges as the door open jam.

Summary of Contents for i-SENSYS MF4300dn

Page 1: ...Aug 22 2008 Service Manual MF4300 Series ...

Page 2: ......

Page 6: ......

Page 12: ...Contents 15 1 1 Solvents Lubricants Table 15 1 ...

Page 13: ...Chapter 1 Introduction ...

Page 14: ......

Page 16: ......

Page 32: ......

Page 33: ...Chapter 2 Basic Operation ...

Page 34: ......

Page 36: ......

Page 38: ......

Page 39: ...Chapter 3 Original Exposure System ...

Page 40: ......

Page 42: ......

Page 44: ...Chapter 3 3 2 F 3 1 ...

Page 49: ...Chapter 4 Original Feeding System ...

Page 50: ......

Page 52: ......

Page 55: ...Chapter 4 4 3 F 4 6 ...

Page 66: ......

Page 67: ...Chapter 5 Laser Exposure ...

Page 68: ......

Page 70: ......

Page 73: ...Chapter 5 5 3 ...

Page 76: ......

Page 77: ...Chapter 6 Image Formation ...

Page 78: ......

Page 80: ......

Page 85: ...Chapter 7 Pickup and Feed System ...

Page 86: ......

Page 88: ......

Page 96: ......

Page 97: ...Chapter 8 Fixing System ...

Page 98: ......

Page 100: ......

Page 108: ......

Page 109: ...Chapter 9 External and Controls ...

Page 110: ......

Page 112: ......

Page 121: ...Chapter 10 Maintenance and Inspection ...

Page 122: ......

Page 124: ......

Page 128: ......

Page 129: ...Chapter 11 Measurement and Adjustments ...

Page 130: ......

Page 132: ......

Page 135: ...Chapter 12 Correcting Faulty Images ...

Page 136: ......

Page 138: ......

Page 144: ...Chapter 12 12 6 2 DCNT PCB 3 Power supply PCB 4 High voltage PCB SW301 Interlock switch ...

Page 145: ...Chapter 13 Error Code ...

Page 146: ......

Page 147: ...Contents Contents 13 1 Error Code 13 1 13 1 1 Error Code Outline 13 1 13 1 2 Error Code 13 1 ...

Page 148: ......

Page 153: ...Chapter 14 Service Mode ...

Page 154: ......

Page 156: ...Contents 14 3 2 3 Sensor test 14 16 14 3 2 4 Key test 14 16 ...

Page 174: ......

Page 175: ...Chapter 15 Service Tools ...

Page 176: ......

Page 177: ...Contents Contents 15 1 Service Tools 15 1 15 1 1 Solvents Lubricants Table 15 1 ...

Page 178: ......

Page 180: ......

Page 181: ...Aug 22 2008 ...

Page 182: ......