Chapter 9

9-4

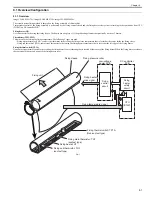

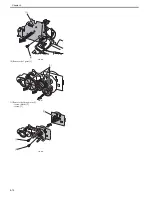

9.2.2 Fixing Pressurizing/Release Control

9.2.2.1 Fixing Sleeve Pressuring/releasing Control

0020-0962

imageCLASS MF9170c / imageCLASS MF9150c / imageCLASS MF8450c

This machine controls the pressure between the fixing sleeve and the fixing pressure roller as needed to prevent the fixing failure and the breakdown of fixing as-

sembly (see MEMO).

Pressuring/releasing of the fixing sleeve is performed by the fixing motor (M1). When the pressure spring pushes the pressure arm, the pressure is applied on the

fixing film. When the fixing motor rotates reversely, the fixing pressure release cam pushes the pressure arm and the pressure on the fixing film is reduced.

The pressuring/releasing status of fixing sleeve has following 3 conditions depending on the position of the fixing pressure releasing cam.

- Pressurized condition (home position)

Fixing film is pushed by the pressure roller.

This condition is called at power-ON, the front cover closed and the cancel of sleep condition.

- Released condition

The fixing film is disengaged with the pressure roller.

This condition is called at power-OFF, JAM occurrence and the entry of sleep mode.

- Slightly pressurized condition

The fixing film is pushed slightly by the pressure roller.

This condition is called at printing envelope.

F-9-3

The pressuring/releasing status of the fixing sleeve is identified by ON/OFF status of the fixing pressure release sensor (SR705) and the rotation period of the fixing

motor (M1).

MEMO:

If pulling out jam paper with fixing sleeve pressured, the fixing sleeve may get damaged. In addition, if the pressurized condition continues for a long time, a mark

may remain on the nip of the fixing sleeve.

To prevent those, there is a mechanism for releasing the fixing sleeve pressure.

Error Codes:

E840

Error in pressure release mechanism

When the pressure control is commanded, if the pressurized condition (home position) cannot be detected after 2.5 sec, the machine stops and an error code

is displayed on a control panel.

Error in no fixing assembly

When the pressure control is commanded, if the pressure release sensor (SR705) is not turned ON after 2.5 sec, the machine stops and a message indicating

the absence of the fixing assembly is displayed.

Fixing pressure roller

Fixing sleeve

Pressure spring

Fixing pressure releasing cam

Fixing pressure release sensor (SR705)

Slightly pressurized

Released

Pressurized

Released

Pressure arm

Slightly pressurized

Pressurized

Summary of Contents for imageCLASS MF9170c

Page 16: ...Chapter 1 Introduction ...

Page 55: ...Chapter 2 Basic Operation ...

Page 61: ...Chapter 3 Main Controller ...

Page 75: ...Chapter 4 Original Exposure System ...

Page 88: ...Chapter 5 Original Feeding System ...

Page 105: ...Chapter 6 Laser Exposure ...

Page 113: ...Chapter 7 Image Formation ...

Page 150: ...Chapter 8 Pickup and Feed System ...

Page 184: ...Chapter 9 Fixing System ...

Page 200: ...Chapter 10 External and Controls ...

Page 230: ...Chapter 11 Maintenance and Inspection ...

Page 233: ...Chapter 12 Measurement and Adjustments ...

Page 237: ...Chapter 13 Correcting Faulty Images ...

Page 260: ...Chapter 14 Error Code ...

Page 272: ...Chapter 15 Special Management Mode ...

Page 280: ...Chapter 16 Service Mode ...

Page 322: ...Chapter 17 Upgrading ...

Page 327: ...Chapter 17 17 4 3 Click Next F 17 4 4 Select a USB connected device and click Next F 17 5 ...

Page 328: ...Chapter 17 17 5 5 Click Start F 17 6 6 Click Yes F 17 7 Download will be started F 17 8 ...

Page 330: ...Chapter 18 Service Tools ...

Page 334: ...Appendix ...

Page 349: ......