8

8

8-176

8-176

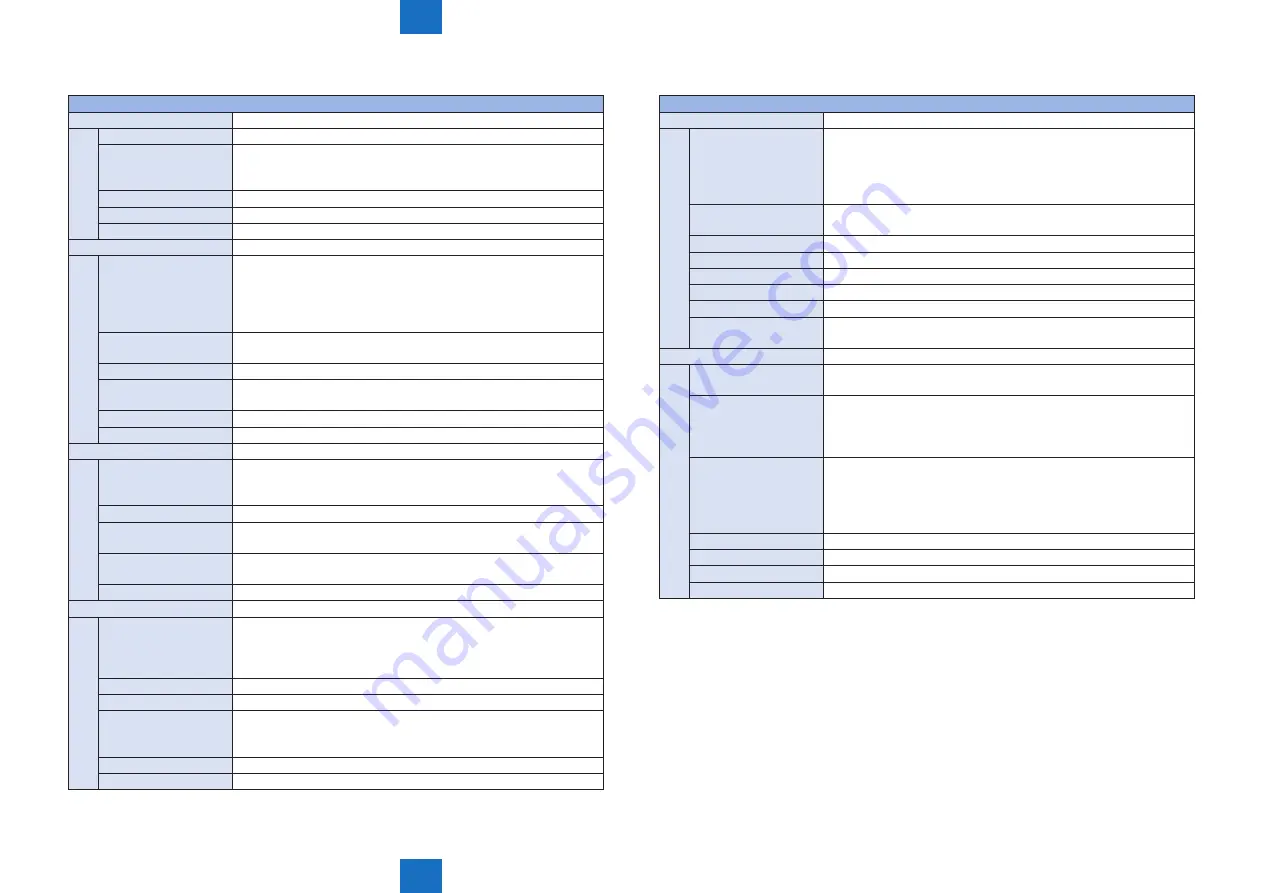

Service Mode > COPIER > ADJUST (Adjustment Mode) > DENS

Service Mode > COPIER > ADJUST (Adjustment Mode) > DENS

■

DEVELOP

COPIER> ADJUST> DEVELOP

DE-NO-DC

Set develp DCbias beside image formation

Lv.1 Details

To set the developing DC bias value besides the image formation.

Caution

• Do not use this at normal service.

• This is effective when the following is set to “0” (potential control is

OFF):COPIER> OPTION> FNC-SW> PO-CNT.

Display/adj/set range

0 to 600

Unit

V

Related service mode

COPIER> OPTION> FNC-SW> PO-CNT

VPP-WB

Set of white band mode develop AC bias

Lv.2 Details

To set the developing AC bias Vpp at white band toner ejection.

As the smaller value is set, the white band is more effective while the

pre-transfer charging wire tends to get dirt.

When the developing bias leakage occurs, set the greater value and

when the reverse foggy occurs, set the smaller value.

Use case

When the leakage from the developing roller (developing bias leak)

occurs in highland low-density environment.

Adj/set/operate method Enter the setting value and press OK key.

Display/adj/set range

0 to 2

0: 1.5 kV, 1: 1.3 kV, 2: 0 V

Default value

2

Related service mode

COPIER> ADJUST> MISC> TBSIS-WB, MAXT-WB

FRQ-DEV

Set of developing bias frequency

Lv.2 Details

Set the frequency of the developing bias.

In the low pressure environment, decrease the value if bias leak

occurs, increase the value if fogging image occurs.

Use case

When image bias leak occurs in the low pressure environment

Adj/set/operate method Enter the setting value (switch negative/positive by -/+ key) and

press OK key.

Display/adj/set range

-2 to 1

-2: 2.0 kHz, -1: 2.5 kHz, 0: 2.7 kHz, 1: 3.0 kHz

Default value

0

BIAS-WB

White band mode developing bias setting

Lv.2 Details

Set the developing AC/DC bias during white band toner ejection.

The combination of AC element and DC element of the developing

bias differs for each set value. Select the appropriate combination for

set value accordingly.

Use case

When fogging image occurs

Adj/set/operate method Enter the setting value and press OK key.

Display/adj/set range

0 to 3

0 : white band bias 0, 1: white band bias 1, 2 : white band bias 2, 3 :

white band bias 3

Default value

0

Related service mode

COPIER> ADJUST> MISC> TBSIS-WB

T-8-36

■

DENS

COPIER> ADJUST> DENS

DENS-ADJ

Density correction of copy image

Lv.1 Details

To correct the density of copy image by changing the F value table.

When the DC controller PCB is replaced or RAM is cleared, enter the

value of service label.

As the value is increased, white gap is reduced and as the value is

decreased, fogging is reduced.

Use case

When fogging or white gap on the high-density area appears on the

copy image.

Adj/set/operate method Enter the setting value and press OK key.

Caution

Density of the printer output image cannot be corrected.

Display/adj/set range

1 to 9

Appropriate target value 4 to 6

Default value

5

Supplement/memo

F value table: this indicates the relation between the original density

and the image density.

P-OFFSET

Dspl/adj of patch detection offset value

Lv.1 Details

To display/adjust the patch detection offset value that is used at the

patch detection sensor.

Use case

When the solid density is out of the specified range even though

there is no issue on the high-voltage or the developing assembly.

When the solid density is out of the specified range after the

replacement of sensor or extended use.

Adj/set/operate method 1) Check that the density change is due to patch detection (high-

voltage etc.)

2) Enter the setting value and press OK key.

3) Execute the D-max control manually.

4) Check the density of solid area of 17 gradations.

Display/adj/set range

-128 to 128

Appropriate target value 0 to 64

Default value

36

Related service mode

COPIER> FUNCTION> MISC-P> P-LPADJ, DMAX-N

Summary of Contents for imagePRESS 1110

Page 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Page 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Page 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Page 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...