2

2

2-66

2-66

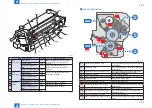

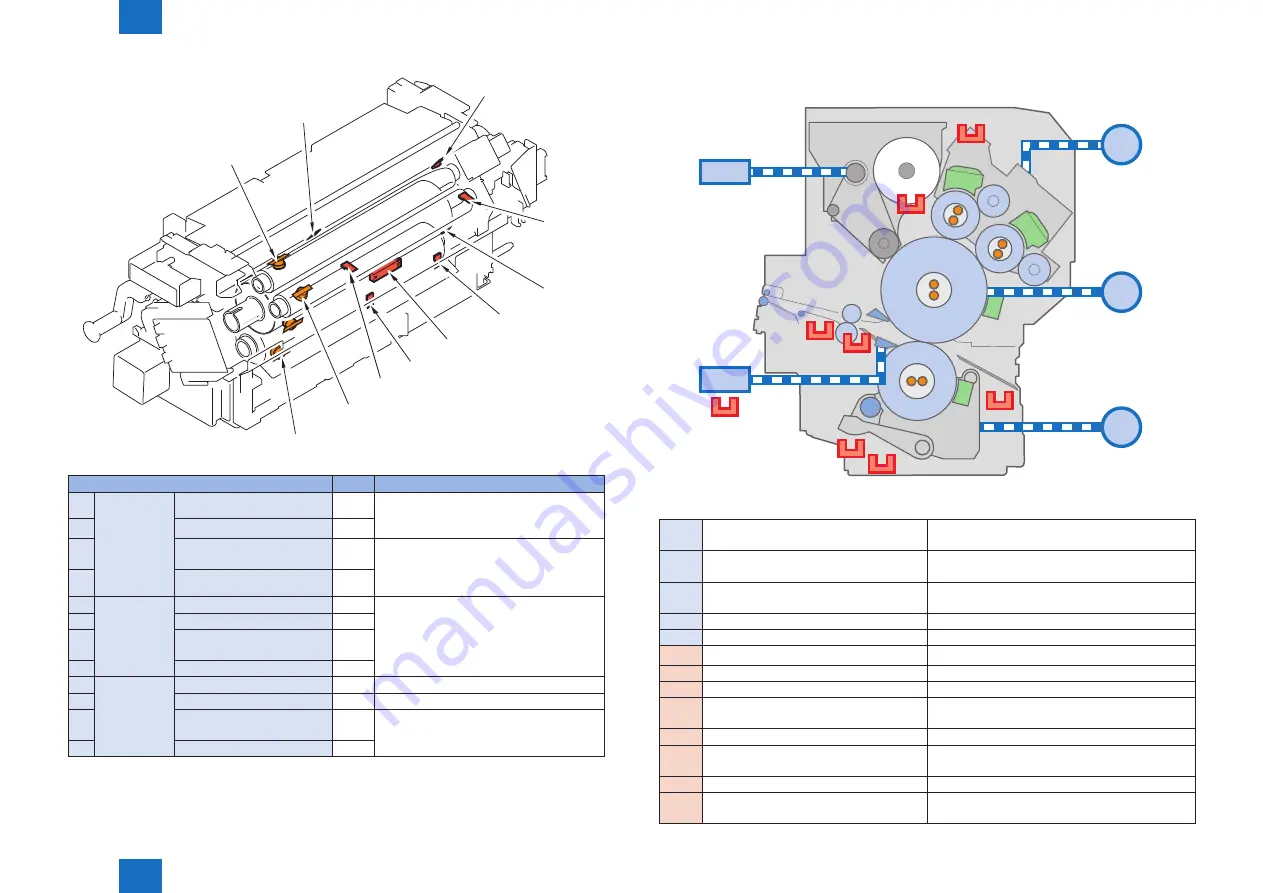

Technology > Fixing System > Overview > Drive Configuration

Technology > Fixing System > Overview > Drive Configuration

TP4

TP1

TP3

THM7

THM2

THM8

THM1

THM6

THM5

TP2

THM4

THM3

Parts Configuration

Code

Function / Method

1 Main

thermistor

Fixing roller

THM2 Noncontact type (temperature control,

detection of abnormal temperature

increase)

2

Pressure roller

THM7

3

External heating upper

roller

THM4 contact type (temperature control,

detection of abnormal temperature

increase)

4

External heating lower roller THM6

5 Sub

thermistor

Fixing roller

THM1 Contact type (detection of abnormal

temperature increase)

6

Pressure roller

THM8

7

External heating upper

roller

THM3

8

External heating lower roller THM5

9 Thermo

switch

Fixing roller

TP1

Contact type (240 +5, -9 deg C)

10

Pressure roller

TP4

Contact type (240 ± 8 deg C)

11

External heating upper

roller

TP2

Contact type (250 ± 10 deg C)

12

External heating lower roller TP3

F-2-89

T-2-57

■

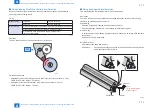

Drive Configuration

M10

M11

M12

SL2

PS16

PS11

PS64

PS10

PS170

PS12

PS13

SL8

PS14

M10

Pressure roller pressure motor

to engage/disengage the pressure roller and the

refresh roller.

M11

Fixing main motor

to drive the fixing roller, the pressure roller and

refresh roller.

M12

External heat engage/disengage motor

to engage/disengage the external heat upper

roller and the external heat lower roller.

SL2

Fixing web solenoid

to take-up the fixing web.

SL8

Lower separation claw disegage solenoid to engage/disengage the lower separation claw.

PS10 Fixing inlet sensor

to detect the residual paper.

PS11 Fixing internal delivery sensor 1

to detect the feed paper.

PS12 Pressure roller position sensor

to detect the position of pressure roller.

PS13 Pressure roller home position sensor

to detect the home position of pressure roller and

refresh roller.

PS14 Fixing cleaning web present sensor

to detect the level of fixing web.

PS16 External heat engage/disengage sensor to detect the disengagement of external heat

upper/lower roller.

PS64 Fixing internal delivery sensor 2

to detect the feed paper.

PS170 Lower separation claw disegage sensor to detect the disengagement of lower separation

claw.

F-2-90

T-2-58

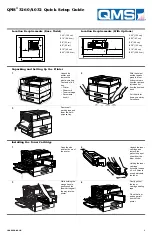

Summary of Contents for imagePRESS 1110

Page 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Page 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Page 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Page 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...