2

2

2-67

2-67

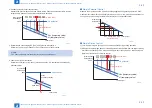

Technology > Fixing System > Overview > Basic Sequence

Technology > Fixing System > Overview > Basic Sequence

■

Basic Sequence

●

Power-ON

WMUP1

WMUP2

WMUP3

STBY

Target temperature

Engage

Disengage

Engage

Disengage

Power On

Main heater(H2)

Sub heater(H3)

Sub heater(H9)

Main heater(H8)

Sub heater(H5)

Main heater(H6)

Sub heater(H7)

External heat engage/disnage

motor(M12)

Main heater(H4)

Fixing roller

Pressure roller

External heat

lower roller

External heat

upper roller

Fixing main motor(M11)

Pressure roller motor(M10)

Fixing roller:

180 degree C

Fixing roller:

205 degree C

Fixing roller:210 degree C

Pressure roller:150 degree C

External heat upper/lower roller:230 degree C

Name of the Interval

Difinition

Warm-

up

Warm-up 1

The interval from when the power is turned on to when the temperature of

the fixing roller surface reaches 180 degree C.

After the temperature is reached, the machine moves to Warm-up 2.

Warm-up 2

The interval until the temperature of the fixing roller surface reaches 205

degree C.

After the temperature is reached, the machine moves to Warm-up 3.

Warm-up 3

he interval until the temperature of the fixing roller surface reaches 210

degree C

Pressure roller: 150 degree C

External heat roller 1, 2: 230 degree C

After the temperature is reached, the machine moves to Standby.

Standby

The status where a print request signal can be received

• Fixing roller: 210 degree C

• Pressure roller: 150 degree C

• External heating roller 1, 2: 230 degree C

* Temperature of the fixing roller main thermistor

• 210 degree C or higher: 200 degree C control

• Lower than 210 degree C: 210 degree C control

F-2-91

T-2-59

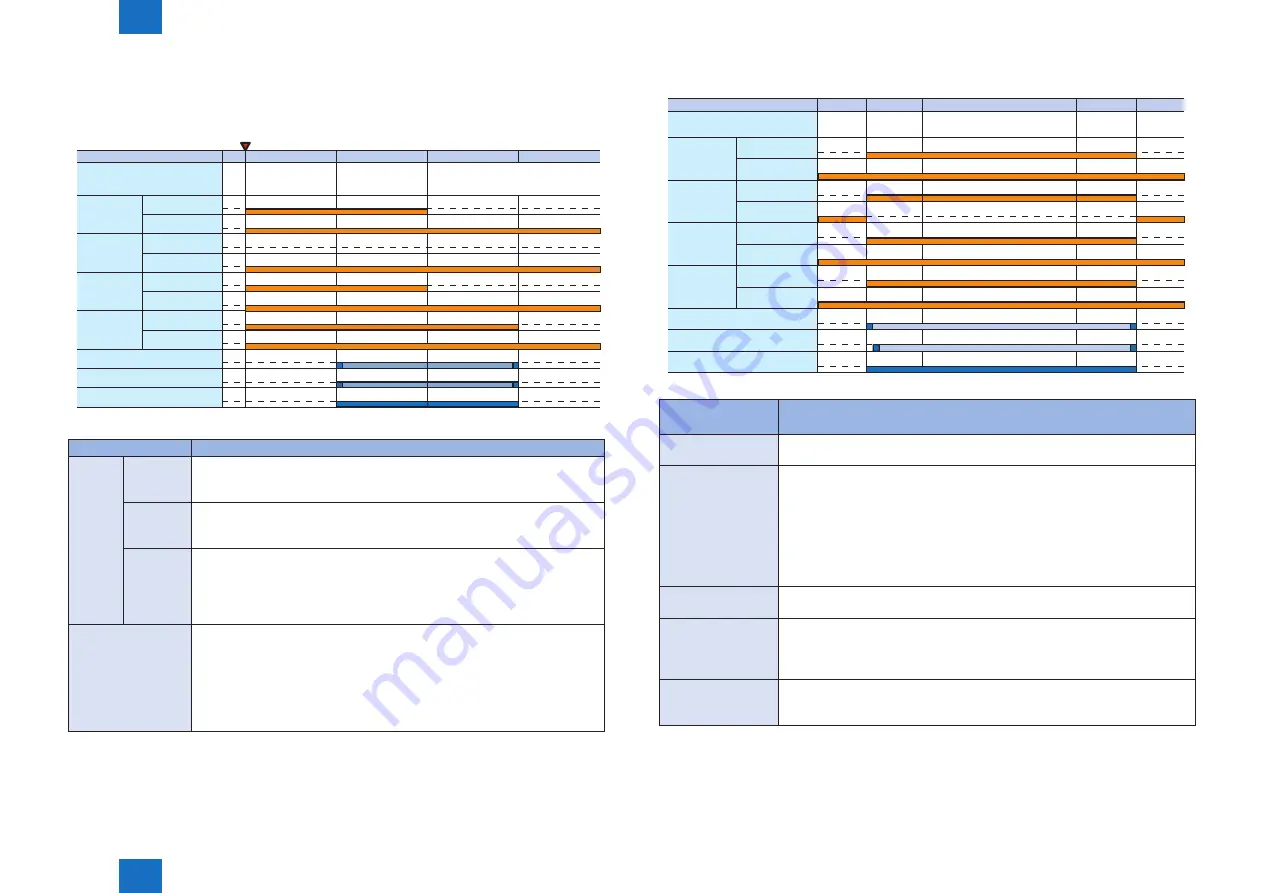

●

Print (A4, Normal mode)

INTR

LSTR

STBY

STBY

Main heater (H2)

Sub heater (H3)

Sub heater (H9)

Main heater (H8)

Sub heater (H5)

Main heater (H6)

Sub heater (H7)

Extermnal heat

engage/disengage motor (M12)

Sub heater (H4)

Fixing roller

Pressure roller

External heat

lower roller

External heat

upper roller

Fixing main motor (M11)

Engage

Disengage

Engage

Disengage

Pressure roller pressure

motor (M10)

Name of the

Interval

Difinition

Initial Rotation

The interval from when a print request signal is received to when an image

signal is sent.

The interval from when image formation starts to when paper is delivered.

Different temperature control table and lighting heater are used depending

on the paper size, paper type, and temperature of the edge of the fixing

roller.

Transmission sequence differs depending on the edge temperature of the

pressure roller at print end.

• Below 180 deg C: transferred to the post rotation

• 180 deg C or higher: transferred to post-rotation 1 -> post rotation 2

Last Rotation

After 5 sec from when the paper goes through the fixing nip, the pressure

roller/external heat roller is disengaged and it stops.

Last Rotation 1

The fans cool down the pressure roller.

If the edge temperature of the pressure roller drops by 10 deg C from the

entry temperature (180 deg C or higher), the machine goes to the post-

rotation 2.

Last Rotation 2

The fans cool down the pressure roller.

If the edge temperature of the pressure roller drops below 165 deg C, the

machine goes to standby mode.

F-2-92

T-2-60

Summary of Contents for imagePRESS 1110

Page 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Page 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Page 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Page 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...