2

2

2-78

2-78

Technology > Fixing System > Various Types of Control > Fixing temperature control

Technology > Fixing System > Various Types of Control > Fixing temperature control

●

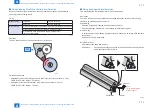

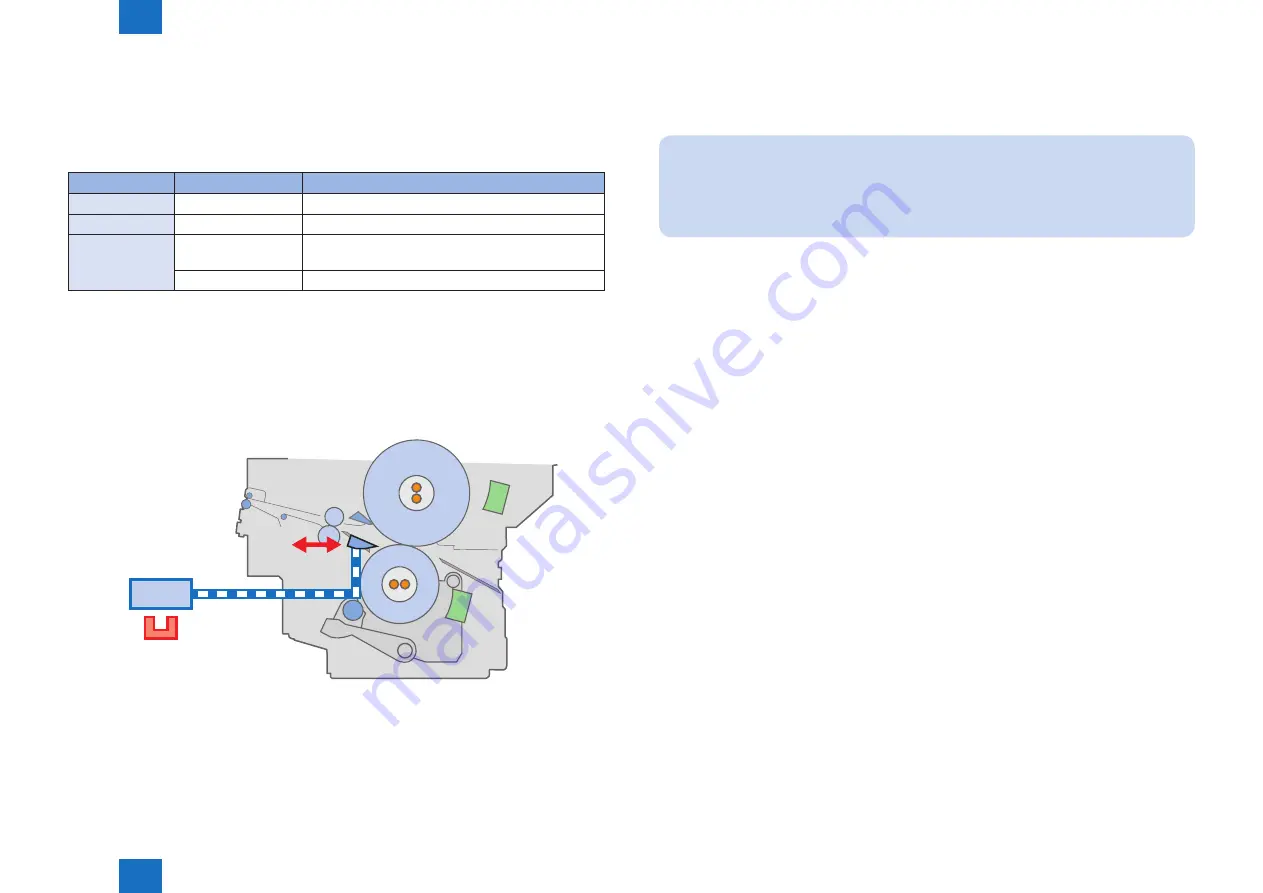

Lower Separation Claw engage/disengage Control

Bring the lower separation claw into contact with the pressure roller to prevent thin paper from

wrapping the pressure roller.

Timing

Interval

Status

Condition

Warm-up

Disengaged

Standby

Disengaged

Engaged

Noncoated paper with a weight of less than 128g.

Coated paper with a weight of 180g or less.

Disengaged

Other paper

Operation

Lower separation claw disegage solenoid (SL8)

Detection

Lower separation claw disegage sensor (PS170)

PS170

SL8

Related Error Code

Lower separation claw disegage error

T-2-74

F-2-107

●

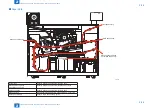

Refresh Roller Drive Control

Prevent an image failure caused by a claw mark of the pressure roller.

MEMO:

Since the lower separation claw comes into contact with the pressure roller, a claw

mark remains on the pressure roller. A claw mark is printed on the 1st side when fixing

is performed to the 2nd side of double-sided printing of thick paper. (Since the control

temperature for thick paper is high (150 degree C), toner on the 1st side melts.)

Timing

• Before execution of double-sided printing of thick paper

• When the paper count value of 5000 prints is passed in the condition where the lower

separation claw is engaged.

Summary of Contents for imagePRESS 1110

Page 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Page 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Page 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Page 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...