2

2

2-89

2-89

Technology > Pickup / Feed System > Pick-up Area Control/Function > Lifter control

Technology > Pickup / Feed System > Pick-up Area Control/Function > Lifter control

Pick-up Area Control/Function

This machine uses an air-pickup method and provides the double-feeding prevention and a

high-speed & stable pickup.

Replacement of a pickup roller is required as a consumable part for the conventional roller-

pickup method.

However, the air pickup method does not require any parts replacement and so improves the

durability of the device.

Adjusting airflow according to the condition can deals with thin paper, thick paper and coated

paper.

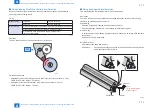

The airflow from the floatation nozzle floats the paper, so that the paper can be attracted to

the suction belt.

At the same time, the airflow from the separation nozzle separates the paper and only the top

sheet is attracted to the suction belt.

The attracted paper is fed to the feeding path by the rotating suction belt.

Paper

Suction belt

Separation nozzle

Floatation

nozzle

Separation

air duct

Floatation

air duct

F-2-118

■

Lifter control

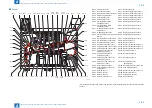

Lifter is driven by lifter motor through lifter wire. By changing the rotation direction on the lifter

motor, the lifter moves up or down.

●

Upward movement control

1. If both deck switch and storage close sensor are on, it is judged that the deck has been set,

and the lifter goes up.

2. The paper surface is monitored through the paper surface sensor 1, the paper surface

sensor 2, the intermediate paper surface sensor, the lifter will stop moving when the paper

lever reaches the lower limit of the pickup available area.

Protection function

• Considering the situation when the lifter keeps moving up even of the lifter upper limit

sensor is turned OFF, there is lower limit switch to prevent damage of the machine caused

by lifter abnormal movement (moving up).

• When some foreign material in the paper stock assembly hits the ceiling, the machine

employs the foreign particle sensor to prevent damage to the lifter wire, resin gear, etc.

●

Downward movement control

1. If the open button of front deck cover is pressed, lifter starts to move downward.

2. The lifter continues to move down until it passes the sensor flag of storage supply position

sensor. (sensor OFF→ON→OFF)

3. If the paper is supplied in this point, since the sensor flag of storage supply position sensoe

is pushed by the paper, the lifter goes further down to the point where the newly supplied

stack of paper passes the sensor flag.

4. Each time paper is supplied, the lifter repeats moving down to the position where the lifter

lower position sensor is turned ON (maximum level for paper supply).

Protection function

• Considering the situation when the lifter keeps moving down even of the lifter lower position

sensor is turned ON, there is lower limit switch to prevent damage of the machine caused

by lifter abnormal movement (moving up).

Summary of Contents for imagePRESS 1110

Page 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Page 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Page 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Page 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...