Version 2

imagePRESS C6010 Customer Expectations Document

Page 37

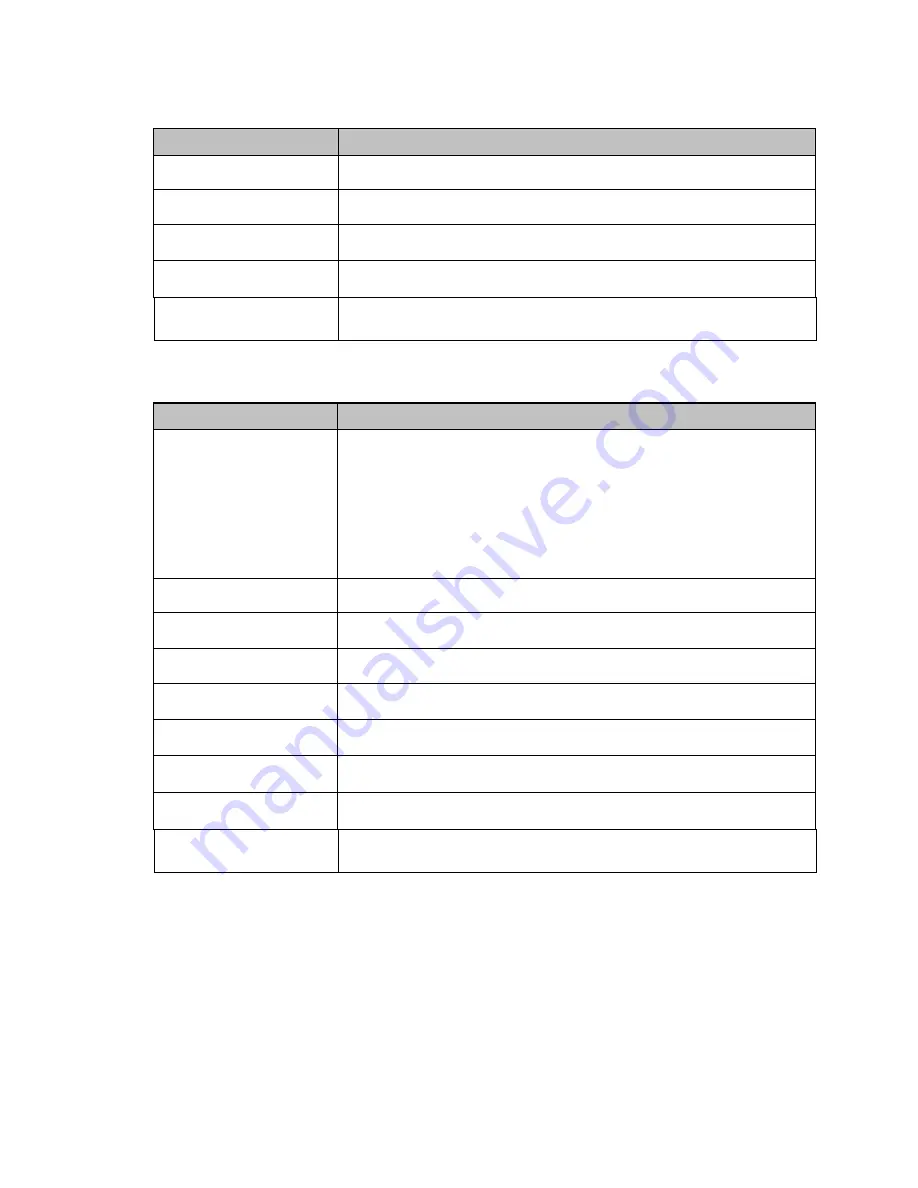

6.13 Card Reader-C1

Item

Specifications

Available Cards

Optical

Card Readout Method

Optical readout

Store/Replay

Replay

Power Source

From the main unit.

Dimensions (H x W x D)/

Weight

1 1/4” x 3 1/2” x 4” (32 mm x 88 mm x 100 mm)

Approximately 10.4 oz (295 g)

6.14 High Capacity Stacker-C1

Item

Specifications

Paper Size

Stack Tray: 11” x 17”, 12” x 18”, 13” x 19”, LGL, LTR, LTRR, EXEC,

Tab Paper (LTR)

*1

, and Irregular Size (8 1/2” x 7 1/8” to 13” x 19 13/64”

(216 mm x 182 mm to 330.2 mm x 487.7 mm))

Proof Tray: 11” x 17”, 12” x 18”, 13” x 19”, LGL, LTR, LTRR, EXEC, STMTR,

Post Card, Tab Paper (LTR), and Irregular Size

(5 1/2” x 7 1/8” to 13” x 19 13/64”

(139.7 mm x 182 mm to 330.2 mm x 487.7 mm))

Paper Capacity

6,000 sheets maximum

Number of Trays

2 trays

Tray Capacity

Proof Tray: 1,000 sheets

Stack Tray: 5,000 sheets

*2

Paper Size/Weight

Size:

13” x 19.2” maximum

Weight:

16 lb bond to 120 lb cover (60 to 325 g/m

2

)

*3

Stacking Modes

Straight, Offset

Power Source

120 to 127 V, 50/60 Hz, 7 A

Maximum Power

Consumption

300 W

Dimensions (H x W x D)/

Weight

48 7/8” x 33 7/8” x 30 1/8” (1,240 mm x 860 mm x 765 mm)

Approximately 478.5 lb (217 kg)

*1 Outputting tab paper to the High Capacity Stacker’s Proof Tray, may improve stacking performance.

*2 The maximum stack capacity may differ, depending on the content or paper type. The maximum stack

capacity is limited to 2,000 sheets when EXEC paper is used.

*3 The paper weight may differ, depending on the main machine.