imagePRESS C7000VPe Service Guide

imagePRESS C7000VPe Service Guide

April 2013

Page 46

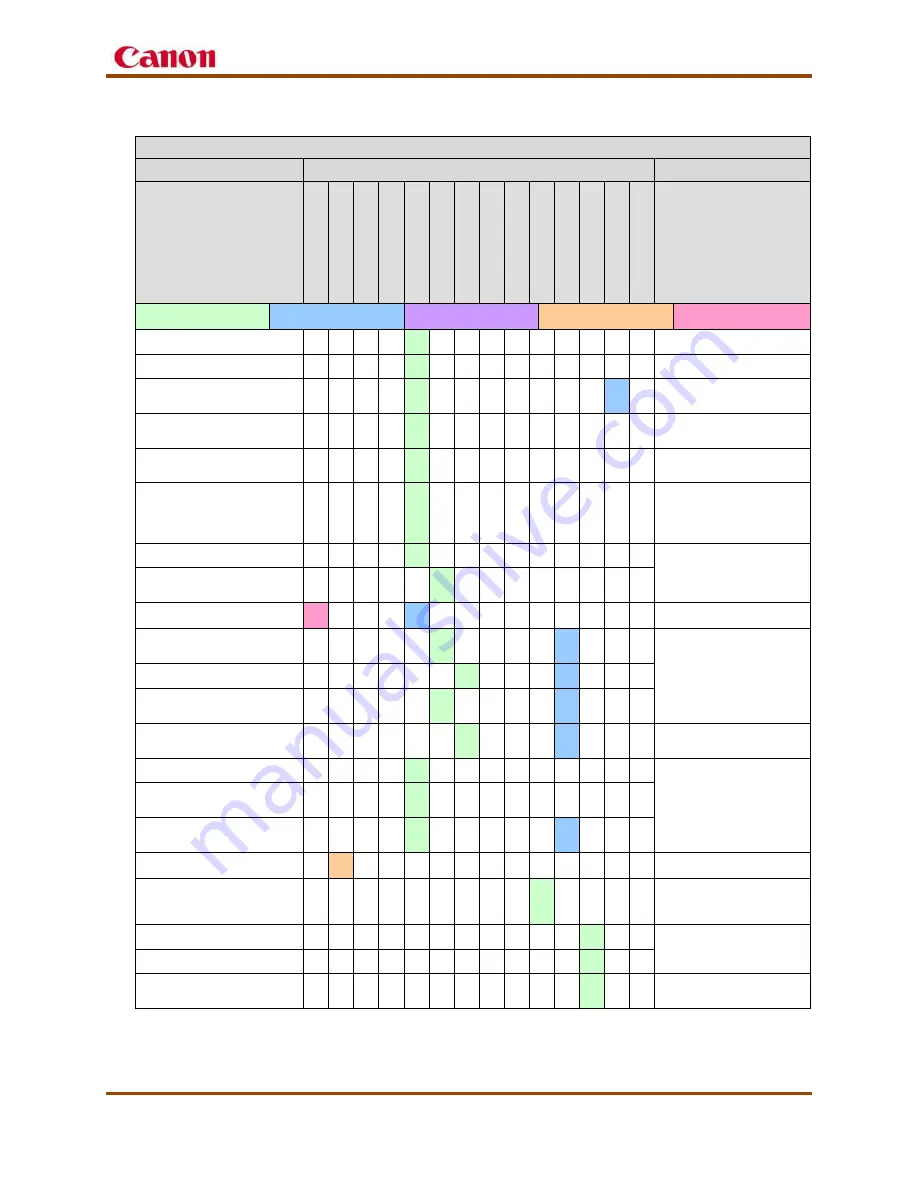

Table 38 – Periodic Maintenance Schedule Continued

Main Unit Periodic Maintenance

Part Name

Estimated Interval

Remarks

Item

A

t

In

s

ta

ll

a

ti

o

n

A

s

N

e

c

e

s

s

a

ry

1

0

0

,0

0

0

p

ri

n

ts

2

0

0

,0

0

0

p

ri

n

ts

2

5

0

,0

0

0

p

ri

n

ts

3

0

0

,0

0

0

p

ri

n

ts

5

0

0

,0

0

0

p

ri

n

ts

6

0

0

,0

0

0

p

ri

n

ts

7

5

0

,0

0

0

p

ri

n

ts

8

5

0

,0

0

0

p

ri

n

ts

1

,0

0

0

,0

0

0

p

ri

n

ts

1

,2

0

0

,0

0

0

p

ri

n

ts

1

,5

0

0

,0

0

0

p

ri

n

ts

4

,5

0

0

,0

0

0

p

ri

n

ts

Clean

Replace

Lubricate

Adjust

Inspect

Sub Hopper Filter

Hopper Right Louver

Secondary Transfer Inlet

Guide (Lower)

Replace every 1,800,000

Secondary transfer outlet

sensor

Use a blower brush.

Secondary transfer outlet

guide

Skew registration skew

roller

Use a blower brush.

When coated paper is used

frequently, clean the Skew Roller

in every 100,000 pages.

Pre-fixing feed belt

Apply using lint free paper and

alcohol.

Shield plate (pre-transfer

charging unit)

Fixing web

Fixing thermistor

(Secondary)

Apply using lint free paper and

alcohol. Replace at the same

time as the fixing rollers.

Fixing thermistor (Primary)

Fixing thermal switch

(Secondary)

Fixing thermal switch

(Primary)

Fixing inlet guide

Use methylketone and lint free

paper.

Delivery upper separation

plate

Delivery lower separation

claw

Auto Gradation Adjustment

Recommended on first power-on

Drum cleaner pre-exposure

unit

Clean using lint free paper with

alcohol

ITB HP sensor

Use a blower brush.

ITB edge sensor

ITB idler roller (ITB-CLN

opposite roller 2)

Apply using lint free paper and

alcohol.

17 Value is based on LTR sized paper. Estimated average values in the field, based on data from supplier.

Data is subject to change depending upon many factors including, without limitation, monthly copy

volume, environment, type of image printed and customer handling of the equipment.