imagePRESS C7000VPe Service Guide

imagePRESS C7000VPe Service Guide

April 2013

Page 53

4.

Warranty Parts for Repair

The APRFs (Authorized Parts Repair Facilities) are authorized by Canon

USA to repair circuit boards for various Canon products. The APRF

program is designed to help your dealership reduce service costs by

having circuit boards repaired instead of purchasing brand new boards.

Each circuit board is live tested and updated to the latest firmware

version prior to returning it to your dealership.

Parts specified on the Canon USA Repairable Parts List must be prepaid

and shipped directly to one of the following Authorized Parts Repair

Facilities.

Log on to

the Canon USA e-Support Web site

at

http://www.support.cusa.canon.com

to view the Canon USA Repairable

Parts List. Go to the Warranty tab, Part Repair Facilities, Repairable

Parts List. See

Figure 7 – e-Support: Authorized Parts Repair Facilities

for more details.

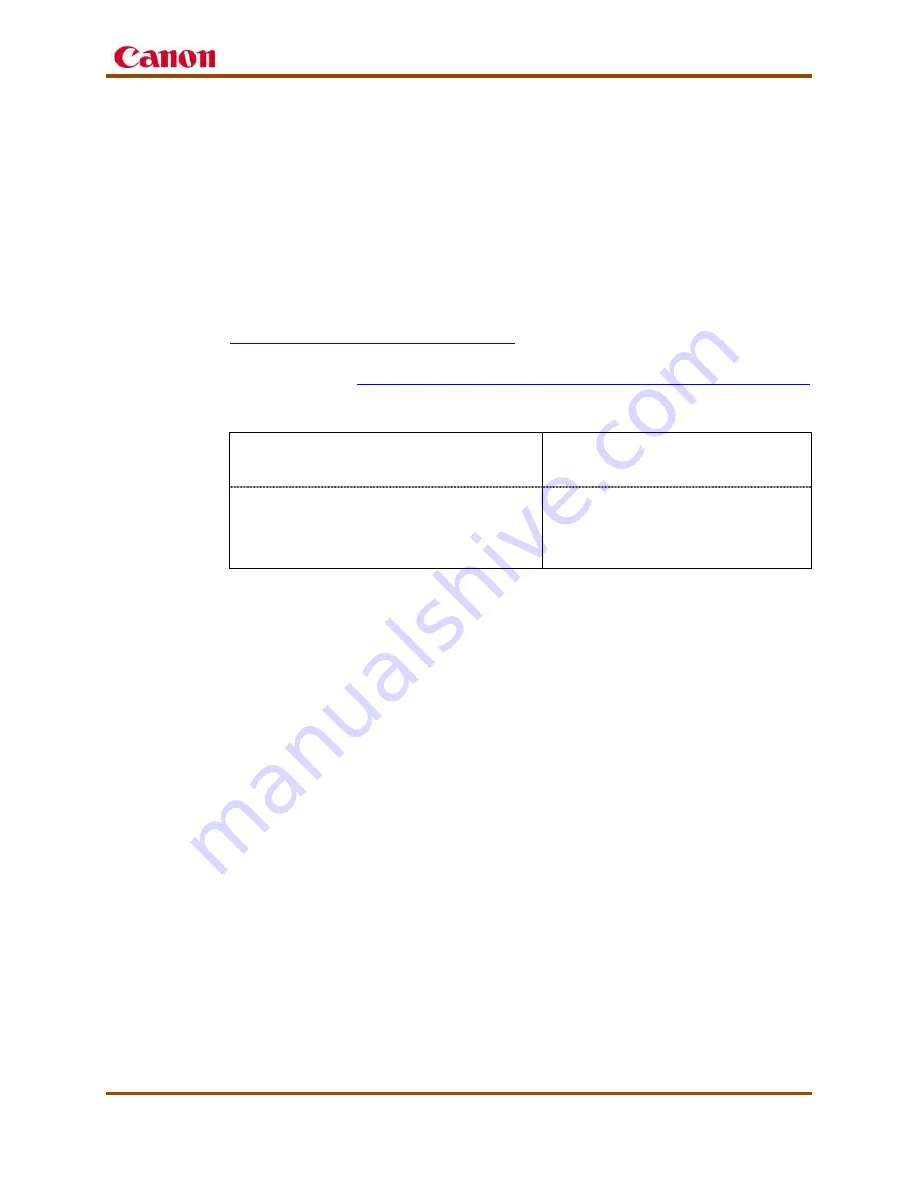

Hytec Dealer Services, Inc.

3600 Vineland Road (Suite 121)

Orlando, FL 32811

Nation-Wide Repair Service, Inc.

16151 Foster Street

Overland Park, KS 66085

Telephone: 1-407-297-1001

Customer Service: 1-866-655-8676

Customer Service:1-800-883-1001

Technical Support: 1-800-798-1814

Technical Support: 1-888-883-2001

Fax: 1-913-631-8372

Fax: 1-407-297-4310

Repairable parts (under warranty) are repaired free-of-charge by the

APRFs. Usually, the turnaround time is approximately five (5) business

days. Once repaired and tested, the parts are shipped back to your

dealership via UPS Ground.

If a part is not repairable, the APRF will contact your dealership, and

Canon USA’s Warranty Control Section will issue a credit to your

account.

To check the status of your part, please contact the APRF.