Chapter 4

4-17

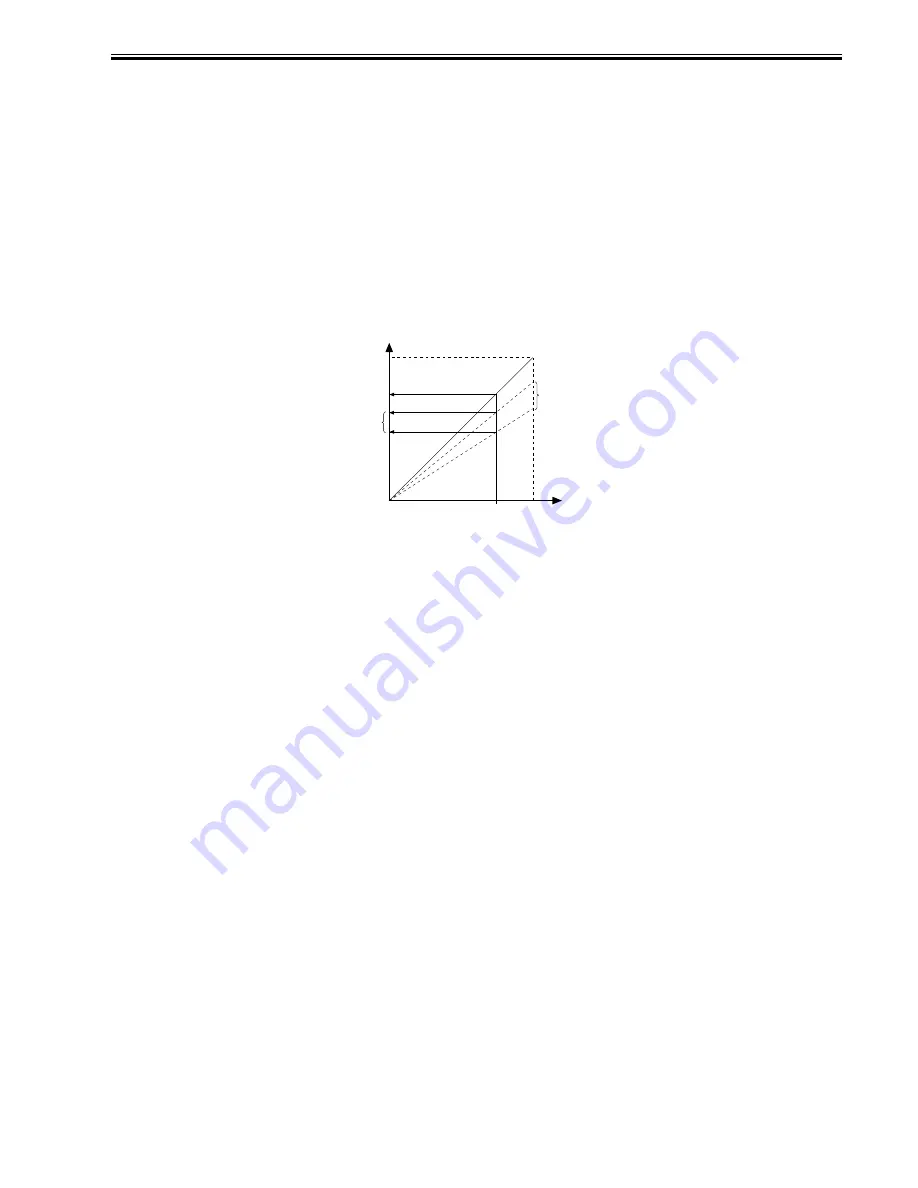

The CMOS sensor outputs are necessary even for the following reasons even when the density of the original is uniform:

(1) Variation in sensitivity among CMOS sensor pixels

(2) Variation in light intensity of rod lens array

The machine performs shading correction to even out the CMOS sensor output.

There are two types of shading correction: shading adjustment performed in the Service mode and shading correction performed for each job.

4.3.6.6 Shading Adjustment

0017-2641

iR2022i / iR2025 / iR2030 / iR2018 / iR2022 / iR2018i

The machine measures the density of the standard white plate, and stores the measured density data. It then processes the stored data to use it as the target value for

shading correction.

4.3.6.7 Shading Correction

0017-2642

iR2022i / iR2025 / iR2030 / iR2018 / iR2022 / iR2018i

The machine performs shading correction for each scan. It measures the density of the standard white plate, and compares the measured value with the target value

stored in the shading correction circuit to use the difference between the two as the shading correction value. The machine uses this shading correction value to

correct the variation among CMOS sensor pixels when scanning the original, thus evening out the image density level.

F-4-32

CMOS

sensor

output

Original density

Standard white plate

Characteristics

before correction

Target

value

Measurement

value

Characteristics

after correction

White

Summary of Contents for imageRunner 2022

Page 1: ...Aug 8 2007 Service Manual iR2030 2025 2022 2018 Series ...

Page 2: ......

Page 6: ......

Page 20: ...Contents ...

Page 21: ...Chapter 1 Introduction ...

Page 22: ......

Page 57: ...Chapter 1 1 33 ...

Page 60: ......

Page 61: ...T 1 11 ...

Page 64: ......

Page 65: ...T 1 12 ...

Page 68: ......

Page 69: ...Chapter 2 Installation ...

Page 70: ......

Page 72: ......

Page 125: ...Chapter 2 2 53 ...

Page 126: ......

Page 127: ...Chapter 3 Main Controller ...

Page 128: ......

Page 130: ......

Page 142: ......

Page 143: ...Chapter 4 Original Exposure System ...

Page 144: ......

Page 170: ......

Page 171: ...Chapter 5 Laser Exposure ...

Page 172: ......

Page 174: ......

Page 181: ...Chapter 6 Image Formation ...

Page 182: ......

Page 184: ......

Page 196: ......

Page 197: ...Chapter 7 Pickup Feeding System ...

Page 198: ......

Page 217: ...Chapter 8 Fixing System ...

Page 218: ......

Page 220: ......

Page 234: ......

Page 235: ...Chapter 9 External and Controls ...

Page 236: ......

Page 255: ...Chapter 10 RDS ...

Page 256: ......

Page 258: ......

Page 268: ......

Page 269: ...Chapter 11 Maintenance and Inspection ...

Page 270: ......

Page 272: ......

Page 275: ...Chapter 12 Standards and Adjustments ...

Page 276: ......

Page 278: ......

Page 281: ...Chapter 12 12 3 ...

Page 282: ......

Page 283: ...Chapter 13 Correcting Faulty Images ...

Page 284: ......

Page 286: ......

Page 299: ...F 13 11 F 13 12 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 ...

Page 300: ......

Page 301: ...Chapter 14 Self Diagnosis ...

Page 302: ......

Page 304: ......

Page 317: ...Chapter 15 Service Mode ...

Page 318: ......

Page 381: ...Chapter 16 Upgrading ...

Page 382: ......

Page 384: ......

Page 411: ...Chapter 17 Service Tools ...

Page 412: ......

Page 414: ......

Page 417: ...Aug 8 2007 ...

Page 418: ......