1

1

1-6

1-6

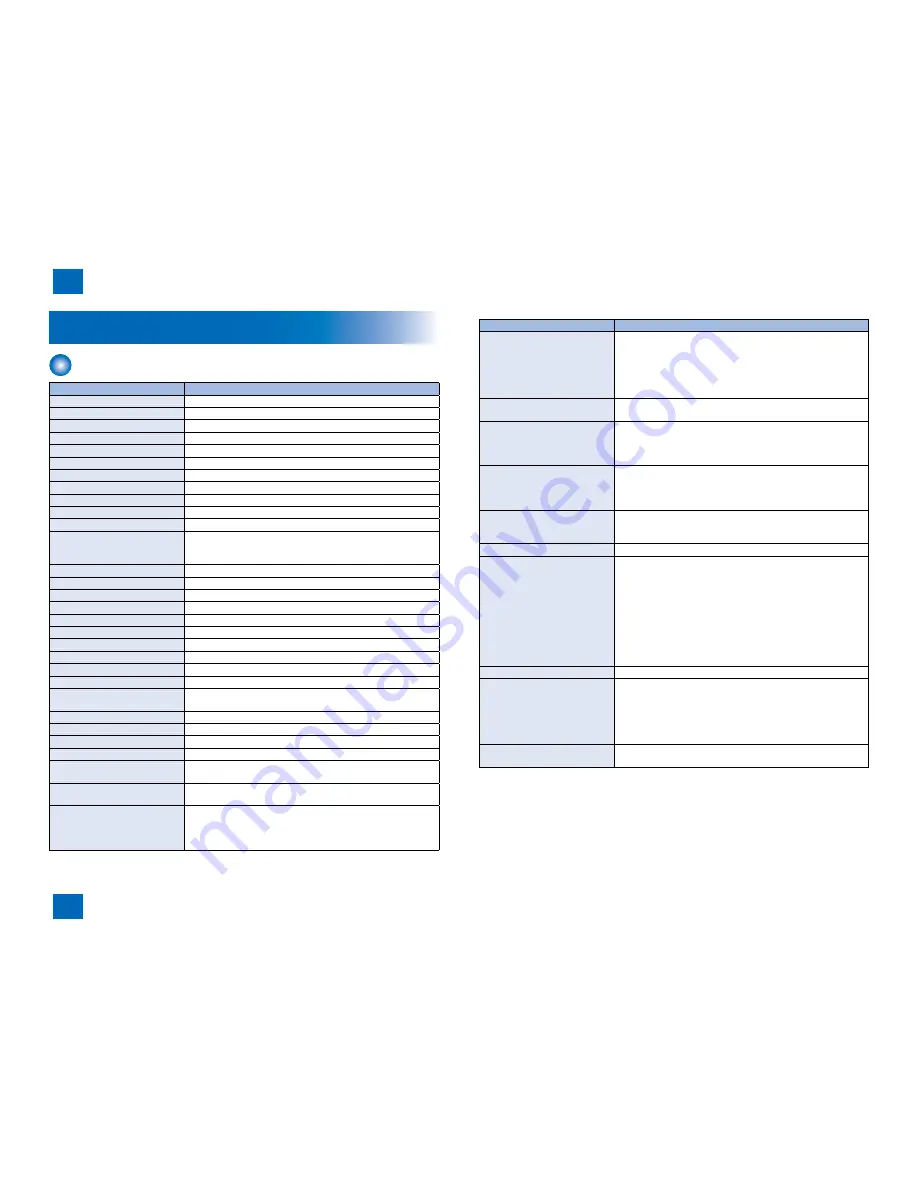

Product Overview > Specifications > Specifications

Product Overview > Specifications > Specifications

Specifications

Specifications

Item

Specifications

Copyboard

Stream reading, original fixed reading

Body

Desktop

Light source type

LED (RGB)

Photosensitive medium

OPC drum (30 mm dia)

Image reading method

CIS

Reproduction method

Indirect electrostatic method

Exposure method

Laser exposure system

Charging method

Roller charge

Development method

Dry single component projection developing

Transfer method

By transfer roller

Separation method

Curvature and static eliminator

Pickup method

550 sheets cassette: Retard separation method

250 sheets cassette: Pad separation method

Manual feed pickup tray: Pad separation method

Fixing method

On demand

Delivery method

Face down delivery (in-body delivery)

Reproduction ratio

25% to 400%

Drum cleaning method

By cleaning blade

Toner type

Magnetic negative charge toner

Toner replenish method

Toner cartridge

Toner level detection function

Yes

Top margin

2.5 -/+ 1.5 mm

Left margin

2.5 -/+ 1.5 mm

Non-image width (leading edge)

2.5 -/+ 1.5 mm

Non-image width (left edge)

2.5 -/+ 1.5 mm

* Using the feeder: 2.5 -/+ 2.0 mm

Warm-up time

At power ON: 30 sec or less

Number of gradations

256 gradations

Reading resolution

600 dpi x 600 dpi

Writing resolution

1200 dpi x 1200 dpi

First print time

imageRUNNER 2530i/2530/2525i/2525: 5.4 sec or less

imageRUNNER 2520i/2520: 6.4 sec or less

Paper type (Cassette 1/3/4)

Weight: 64 g/m2 to 90 g/m2

Type: Plain, Recycled, Color (64 g/m2 to 80 g/m2), 3-hole punch

Paper type (Cassette 2)

Weight: 64 g/m2 to 90 g/m2

Type: Plain, Recycled, Color (64 g/m2 to 80 g/m2), 3-hole punch,

Envelopes* (No.10 (COM10), ISO-B5, Monarch, ISO-C5, DL)

* The optional Envelope Feeder Attachment-D1 is required.

Item

Specifications

Paper type

(Manual feed pickup tray)

Weight: 64 g/m2 to 128 g/m2

Type: Plain, Recycled, Color (64 g/m2 to 80 g/m2), 3-hole punch,

Bond (75 g/m2 to 90 g/m2), Heavy Paper 1 (81 g/m2 to 90

g/m2), Heavy Paper 2 (91 g/m2 to 105 g/m2), Heavy Paper 3 (106

g/m2 to 128 g/m2), Transparencies, Labels, Envelopes (No.10

(COM10), ISO-B5, Monarch, ISO-C5, DL)

Paper size (Cassette 1/3/4)

Standard size (A4, A4R, A3, A5R, B4, B5, B5R, LTR, LTTR, LG,

11" x 17", STMTR)

Paper size (Cassette 2)

Standard size (A4, A4R, A3, A5R, B4, B5, B5R, LTR, LTTR, LG,

11"" x 17"", STMTR)

Envelopes* (No.10 (COM10), ISO-B5, Monarch, ISO-C5, DL)

* The optional Envelope Feeder Attachment-D1 is required.

Paper size

(Manual feed pickup tray)

Standard size (A4, A4R, A3, A5R, B4, B5, B5R, LTR, LTTR, LG,

11"" x 17"", STMTR)

Free size (99 mm x 297 mm to 148 mm x 432 mm)

Envelopes (No.10 (COM10), ISO-B5, Monarch, ISO-C5, DL)

Pickup capacity

550 sheets cassette: 550 sheets (80g/m2)

550 sheets cassette: 250 sheets (80g/m2)

Manual feed pickup tray: 100 sheets (80g/m2)

Duplex method

Through path duplex

Acoustic noise

imageRUNNER 2530i/2530:

operation: 69.50 dB or less *1 / stand-by: 43.00 dB or less *2

imageRUNNER 2525i/2525:

operation: 67.75 dB or less *1 / stand-by: 43.00 dB or less *2

imageRUNNER 2520i/2520:

operation: 66.00 dB or less / stand-by: 43.00dB or less *2

*1 Except for china model. China model: 66.00 dB or less

(operation)

*2 Except for china model. China model: 43.00 dB or less (stand-

by)

Ozone

Max: 0.035 ppm or less

Power supply rating

imageRUNNER 2530/2525 (US):

120 - 127 V AC, 50Hz/60Hz, 6.9 A

imageRUNNER 2520 (US):

120 - 127 V AC, 50Hz/60Hz, 6.2 A

imageRUNNER 2530i/2530/2525i/2525/2520i/2520 (Except US):

220 - 240 V AC, 50Hz/60Hz, 3.3 A

Maximum power consumption

120 - 127 V model: Approx. 1.473 kW

220 - 240 V model: Approx. 1.542 kW

Summary of Contents for IMAGERUNNER 2530

Page 1: ...9 8 7 6 5 4 3 2 1 imageRUNNER 2530 2525 2520 Series Service Manual...

Page 4: ...Blank Page...

Page 16: ...1 1 Product Overview Product Overview Product Lineup Feature Specifications Name of Parts...

Page 111: ...3 3 Periodical Service Periodical Service Consumable Parts and Cleaning Parts...

Page 159: ...5 5 Adjustment Adjustment Outline Adjustment when replacing parts Image position adjustment...

Page 166: ...6 6 Troubleshooting Troubleshooting Upgrading Targets and Procedure...

Page 171: ...7 7 Error Code Error Code Overview Error Code Jam Code Alarm Code...

Page 186: ...8 8 Service Mode Service Mode Outline Details of Service Mode...

Page 321: ...Service Tools General Circuit Diagram Appendix...