CHAPTER 14 TROUBLESHOOTING

14-20

COPYRIGHT © 1999 CANON INC. CANON imageRUNNER 400/330 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

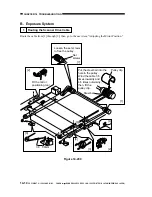

E. Fixing System

1

When Mounting the Fixing

Heater

1) Do not touch the heater surface.

2) Orient it so that the side with the longer

heater wire is toward the front.

3) Mount the main heater (700 W) to the

right and the sub heater (600 W) to the left

when viewing the fixing assembly from

the front.

4) Connect the right faston of the heater to

the main heater and the upper faston to the

sub heater when viewing it from the rear.

(The fastons are found at the rear.)

Main heater

Sub heater

(Delivery side)

(pick-up side)

Upper fixing roller

Figure 14-226

2

Positioning the Fixing

Assembly Paper Guide

Caution:

If you removed the inlet guide plate, you

would need to adjust the position of the

inlet guide. To avoid the work, do not

loosen the mounting screw (paint-

locked) on the inlet guide mount;

otherwise, be sure to set it to its initial

position by referring to the scale on the

fixing assembly.

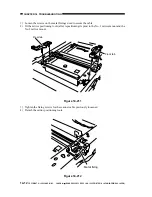

3

Adjusting the Lower Fixing

Roller Pressure (nip)

If you have replaced the upper fixing

roller or the lower fixing roller, or if fixing

faults occur, make the following adjustments:

If you are taking measurements while the

fixing roller is cold, leave the machine alone

for 15 min after it ends its wait period and

make 20 copies before taking measurements:

<Taking Measurements>

1) Make an A4 solid black copy, and make a

copy of it. Set the output in the

multifeeder.

2) Select NIP-CHK in service mode

(FUNCTION>FIXING), and press the

OK key.

3) The paper will be picked up and is stopped

between the fixing rollers temporarily;

then, it will automatically be discharged

in about 20 sec.

4) Measure the width of the area where toner

is shiny (Figure 14-227).

Figure 14-227

Caution:

a and c are points 10 mm from both

edges of the copy paper.

c

a

Center of

the copy

b

A3

(Feeding

direction)

* Measured when the upper/lower roller is

adequately heated.

Table 14-201

Point

b

a-c

Measurements*

5.5 ±0.3 mm

0.5 mm or less