Specifying the System Manager Settings

6-2

6

System Man

age

r Settings

Specifying the System Manager Settings

You can set an ID and a password for the System Manager. Once the System

Manager ID/password is set, restrictions can be placed on storing or changing the

System Settings.

IMPORTANT

Attaching the optional Card Reader-C1 erases the System Manager ID and System

Password that have been stored.

NOTE

•

If the optional Card Reader-C1 is attached, the numbers 1 to 300 cannot be used for the

System Manager ID. Numbers 1 to 300 are reserved for control cards by default.

•

For instructions on entering characters, see "Entering Characters from the Touch Panel

Display," on p. 2-22.

•

You can enter a maximum of 32 characters for a name, contact, or comment, and 64

characters for an e-mail address.

•

The maximum number of digits that you can store for the System Manager ID and

System Password is seven. If you enter fewer than seven digits for either setting, the

machine stores them with leading zeros.

- Example: If <321> is entered, <0000321> is stored.

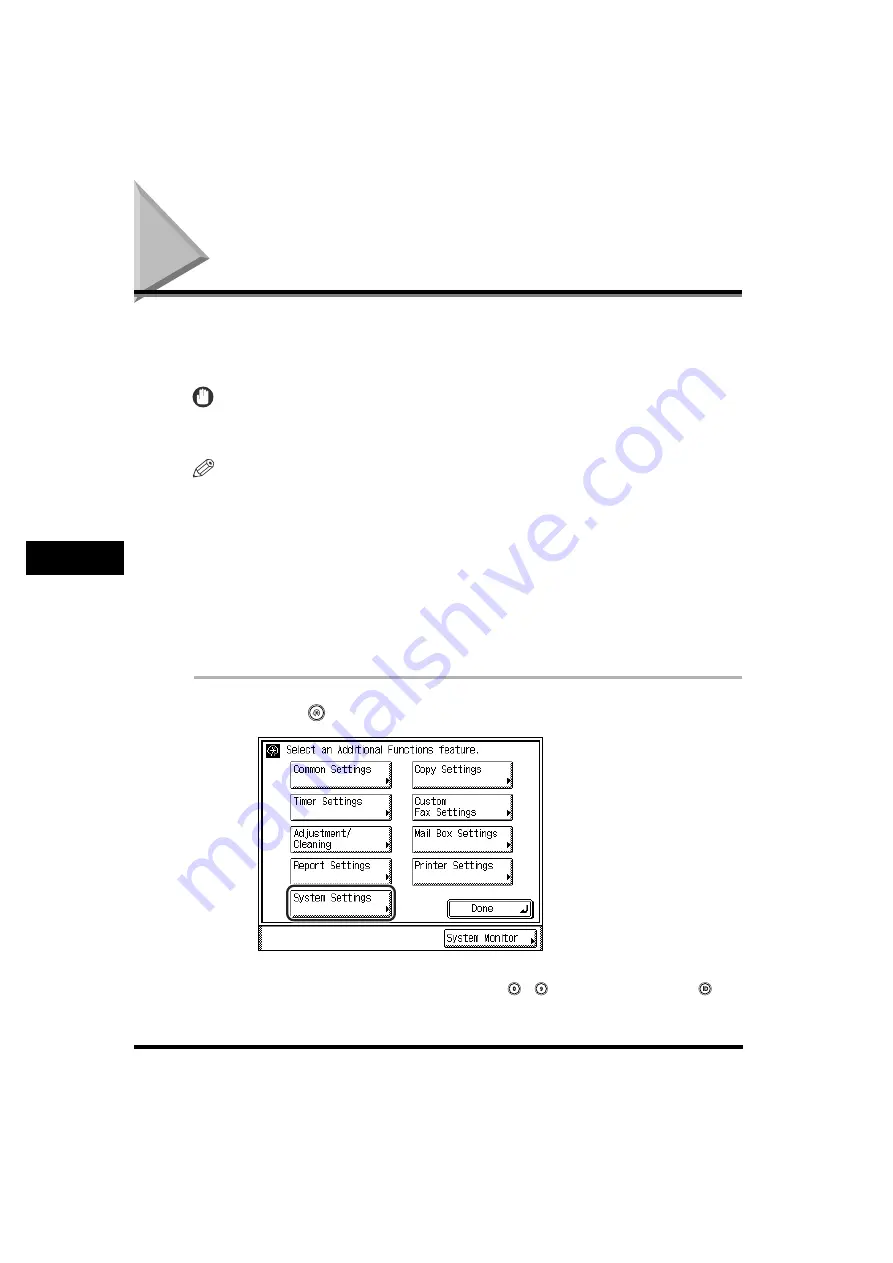

1

Press

(Additional

Functions)

➞

[System Settings].

If the System Manager ID and System Password have been set, enter the System

Manager ID and System Password using

-

(numeric keys)

➞

press

(ID).

Summary of Contents for imageRUNNER 3530

Page 2: ...0 ...

Page 3: ...imageRUNNER 3530 2830 2230 Reference Guide 0 ...

Page 234: ...Adjusting the Machine 4 78 4 Customizing Settings ...

Page 252: ...Printing Secured Documents 5 18 5 Checking Job and Device Status ...

Page 300: ...License Registration 6 48 6 System Manager Settings ...

Page 352: ...Consumables 7 52 7 Routine Maintenance ...

Page 430: ...If the Power Does Not Turn ON 8 78 8 Troubleshooting ...

Page 450: ...Index 9 20 9 Appendix ...

Page 458: ...System Management of the imageRUNNER 3530 2830 2230 VIII ...

Page 459: ...0 ...