Paper Deck-AD1/Paper Deck-AE1 (Optional)

7-27

7

Routin

e Ma

intena

nce

9

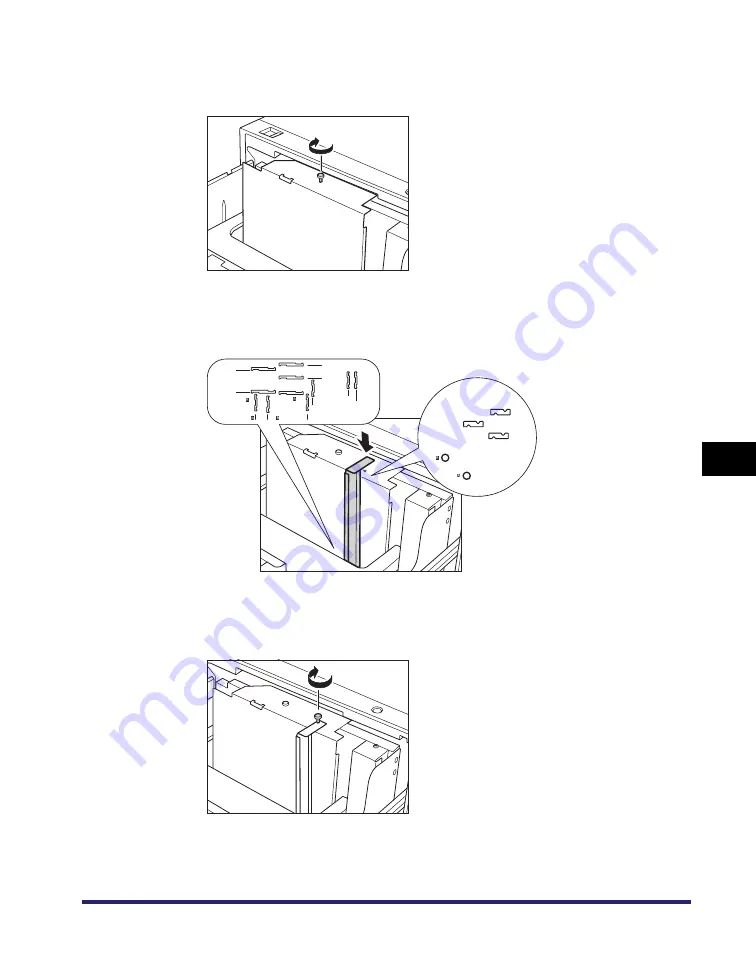

Fix the back size switch plate B to the paper deck with the

white screw by turning it clockwise.

10

Insert and align size switch plate A with the marks for the

desired paper size.

11

Fix the size switch plate A with the white screw by turning it

clockwise.

11x17

LTR

A3

A4

A4

B4

B5

A3

11x17

B4

LGL

LGL

LTR

LTR

A4

B5/B4

A4/A3

LTR/11x17

LTR

A4

Summary of Contents for ImageRunner 5050

Page 2: ......

Page 3: ...imageRUNNER 5075 5065 5055 5050 Reference Guide 0 Ot ...

Page 48: ...System Settings 1 28 1 Before You Start Using This Machine ...

Page 102: ...Available Paper Stock 2 54 2 Basic Operations ...

Page 214: ...Adjusting the Machine 4 68 4 Customizing Settings ...

Page 230: ...Priority Printing 5 16 5 Checking Job and Device Status ...

Page 257: ...License Registration 6 27 6 System Manager Settings 3 Press OK ...

Page 306: ...Restricting Printer Jobs 6 76 6 System Manager Settings ...

Page 376: ...Consumables 7 70 7 Routine Maintenance ...

Page 500: ...Index 9 22 9 Appendix ...

Page 501: ......