Chapter 14

14-20

14.7.3 After Replacing the DC Controller

PCB

0010-9329

Before Starting the Work (backing up the

data)

If possible, perform the following:

- Using the SST, download the data stored in the

RAM of the DC controller.

- Print out the user mode/service mode data.

1) Turn on the power, and execute the following

service mode:

COPIER > FUNCTION > CLEAR > DC-CON

2) If the data has been successfully downloaded

using the SST as instructed in step 1) above, up-

load it.

3) Using the following service mode item, specify

the order of connecting delivery accessories:

COPIER > OPTION > ACCPSD-D > ACC1 to

ACC8

4) Set the values indicated on the service mode

for their respective service mode items.

5) Set '0' for the following service mode item:

COPIER > OPTION > BODY > FIX-EXP (fixing

smear repression mode)

6) Execute the following service mode item:

COPIER > FUNCTION > MISC-P > CL-ADJ

COPIER > FUNCTION > SENS-ADJ > OP-

SENS (Level 2)

7) Enter the values indicated on the label attached

to the new DC controller PCB for their

respective service mode items:

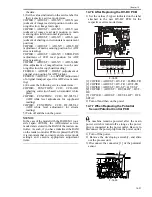

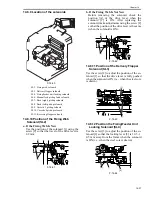

F-14-37

[1] COPIER > ADJUST > DEVELOP > D-HV-

DE

[2] COPIER > ADJUST > HV-TR > D-HV-TR

[3] COPIER > ADJUST > HV-TR > D-PRE-TR

[4] COPIER > ADJUST > HV-SP > D-HV-SP

[5] COPIER > ADJUST > DEVELOP > OFF-

SETDA

8) Turn off and then on the power.

14.7.4 After Replacing the Reader

Controller PCB <iR7105/7095>

0011-8214

Before Starting the Work (backing up the

data)

If possible, perform the following:

- Using the SST, download the data stored in the

RAM of the reader controller PCB.

- Print out the user mode/service mode data.

1) Turn on the power, and execute the following

service mode item:

COPIER > FUNCTION > CLEAR > R-CON

2) If the data has successfully been downloaded

using the SST before the replacement, upload

the data.

3) Set the values indicated on the service label for

their respective service mode items.

COPIER > ADJUST > ADJ-XY > ADJ-X (ad-

justment of image read start position in sub scan-

ning direction; image lead edge)

COPIER > ADJUST > ADJ-XY > ADJ-Y (ad-

justment of image read start position in main

scanning direction; horizontal registration)

COPIER > ADJUST > ADJ-XY > ADJ-S (ad-

justment of shading correction data measurement

position)

COPIER > ADJUST > ADJ-XY > ADJ-Y-DF

(adjustment of main scanning position for ADF

stream reading)

COPIER > ADJUST > ADJ-XY > ADJ-Y-FX

(adjustment of main scanning position for ADF

fixed reading)

COPIER > ADJUST > ADJ-XY > ADJ-X-MG

(fine-adjustment of magnification in sub scan-

ning direction for copyboard reading)

4) Execute the following service mode item:

COPIER> FUNCTION> CCD> CCD-ADJ

(shading correction based on standard white

plate)

5) Turn off and then on the power.

14.7.5 After Replacing the Reader

Controller PCB <iR7086>

0011-8729

Before Starting the Work (backing up the

data)

If possible, perform the following:

- Using the SST, download the data stored in the

RAM of the reader controller PCB.

- Print out the user mode/service mode data.

1) Turn on the power, and execute the following

service mode item:

COPIER > FUNCTION > CLEAR > R-CON

2) If the data has successfully been downloaded

using the SST before the replacement, upload

DC+09+28+24+09+25

[1] [2] [3] [4] [5]

Summary of Contents for IMAGERUNNER 7095 PRINTER

Page 20: ...Chapter 1 Introduction...

Page 46: ...Chapter 2 Installation...

Page 88: ...Chapter 3 Basic Operation...

Page 94: ...Chapter 4 Main Controller...

Page 116: ...Chapter 5 Original Exposure System...

Page 165: ...Laser Exposure Chapter 6...

Page 175: ...Chapter 7 Image Formation...

Page 231: ...Chapter 8 Pickup Feeding System...

Page 287: ...Chapter 9 Fixing System...

Page 312: ...Chapter 10 External and Controls...

Page 346: ...Chapter 11 MEAP...

Page 350: ...Chapter 12 RDS...

Page 360: ...Chapter 13 Maintenance Inspection...

Page 375: ...Chapter 14 Standards Adjustments...

Page 407: ...Chapter 15 Correcting Faulty Images...

Page 433: ...Chapter 16 Self Diagnosis...

Page 460: ...Chapter 17 Service Mode...

Page 559: ...Chapter 18 Upgrading...

Page 583: ...Chapter 19 Service Tools...

Page 588: ...APPENDIX...

Page 615: ......