Laser Safety

Since radiation emitted inside the machine is completely confined within protective housings and external covers, the laser beam

cannot escape from the machine during any phase of user operation.

Therefore this machine is classified in Class 1 laser products that are regarded as safe during normal use according to

International Standard IEC60825-1.

Handling of Laser System

This machine is classified in Class 1 laser products.

However, inside the machine, Class 3B laser beam is emitted and is hazardous when entered into an eye.

When servicing the area around the laser assembly, be sure to turn off the main power.

If you must service while the power is turned on, be sure to keep the followings:

• Do not use a screwdriver or tools that have a high level of reflectance in the laser path.

• Remove watches and rings before starting the work. (They can reflect the laser beam, possibly hitting an eye.)

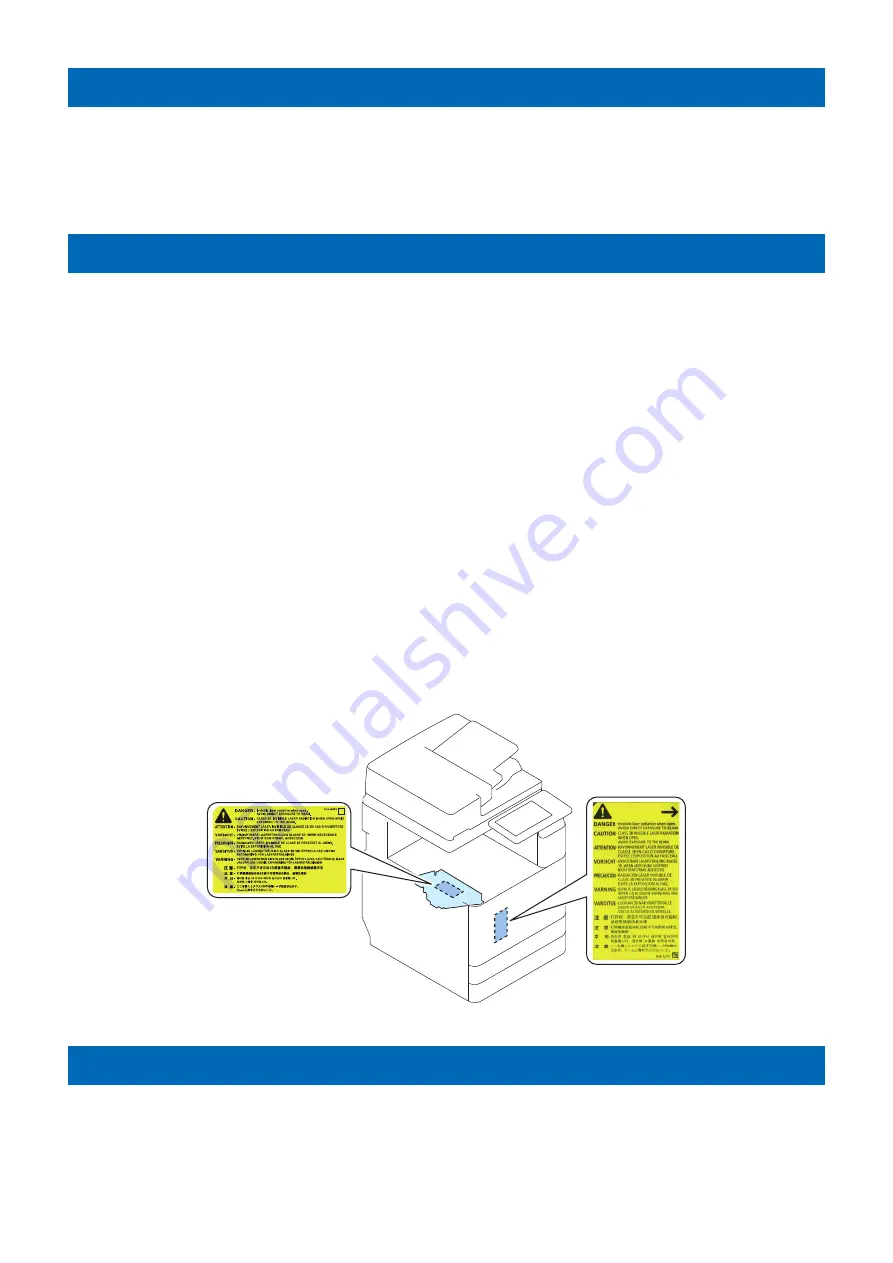

The machine's covers that confine laser beam radiation are identified by means of warning label (Figure). If you must open the

cover, be sure not to enter the laser beam into an eye during the work.

The following warnings are given to comply with Safety Principles (EN60950-1).

Diese Maschine ist der Klasse 1 der Laserprodukte zugeordnet.

Innerhalb der Maschine wird jedoch ein Laserstrahl der Klasse 3B ausgestrahlt und es ist gefährlich, wenn dieser Strahl in die

Augen gerät.

Bei Servicearbeiten am oder in der Nähe des Laserteils zuerst das Hauptgerät abschalten.

Bei Servicearbeiten, die unbedingt bei eingeschaltetem Gerät durchgeführt werden müssen, auf jeden Fall die folgenden

Vorsichtsmaßnahmen beachten.

• Keine stark reflektierenden Schraubenzieher oder ähnliche Werkzeuge direkt in den Lichtpfad des Laserstrahls bringen.

• Vor Beginn der Arbeit Uhren, Ringe und ähnliche Gegenstände abnehmen. (Reflektierende Laserstrahlen könnten sonst in

die Augen geraten.)

Die Geräte-Abdeckungen, die Laserstrahlen reflektieren können, werden durch einen besonderen Warnaufkleber

gekennzeichnet (siehe Bild).

Muss die Abdeckung geöffnet werden, besondere Vorsicht walten lassen, damit der Laserstrahl nicht in die Augen gerät.

Turn power switch ON

The machine is equipped with 2 power switches: main power switch and control energy saver key.

The machine goes on when the main power switch is turned on (i.e., other than in low power mode, sleep mode).

Safety Precautions

2

Summary of Contents for imagerunner advance 4551i

Page 19: ...Product Overview 1 Product Lineup 7 Features 13 Specifications 16 Name of Parts 26 ...

Page 155: ...Periodical Service 3 Consumable Parts List 143 Cleaning Check Adjustment Locations 146 ...

Page 392: ...Error Jam Alarm 7 Overview 380 Error Code 383 Jam Code 509 Alarm Code 520 ...

Page 545: ...Service Mode 8 Overview 533 COPIER 549 FEEDER 845 SORTER 851 BOARD 871 ...

Page 892: ...Unpacking 1 2 1200 mm 840 mm 769 mm 1230 mm 2430 mm 3 9 Installation 879 ...

Page 895: ...3 4 NOTE Keep the removed screws for relocating the host machine 2x 5 6 7 9 Installation 882 ...

Page 896: ...8 9 10 1x Installing the Air Filter 1 9 Installation 883 ...

Page 897: ...2 3 Installing the Drum Unit 1 2 3 9 Installation 884 ...

Page 899: ...8 NOTE The screw removed at procedure 4 is used 1x 9 10 11 12 9 Installation 886 ...

Page 923: ...5 6 NOTE Use the screws and Rubber Caps removed in step 1 2x 7 2x 9 Installation 910 ...

Page 935: ...7 1x 8 9 6x 10 2x 9 Installation 922 ...

Page 936: ...11 Installing the NFC Kit 1 2 2x 3 TP M3x4 1x 9 Installation 923 ...

Page 938: ...4 5 1x 6 9 Installation 925 ...

Page 985: ...8 2x 2x TP M4x8 Black When installing the USB Keyboard 1 9 Installation 972 ...

Page 991: ...7 4x 8 1x 1x Lower Cover 9 1x 10 1x 1x 9 Installation 978 ...

Page 992: ...11 1x 1x 12 1x 13 TP M3x12 2x 14 4x TP M3x6 9 Installation 979 ...

Page 997: ...Installation Procedure 1 2 2x 3 2x 4 6x 5 4x 9 Installation 984 ...

Page 998: ...6 7 NOTE Do not close the Wire Saddle 1x 1x 8 9 9 Installation 985 ...

Page 1003: ...2 1x 1x 3 2x 2x 4 9 Installation 990 ...

Page 1012: ...2 1x 1x 3 2x 2x 4 9 Installation 999 ...

Page 1014: ...7 CAUTION The connector must be contacted TP㸹M3x6 3x 1x 8 4x 9 9 Installation 1001 ...

Page 1016: ...13 4x 14 15 Binding M4x16 Binding M3x16 2x M3x16 M4x16 16 Binding M4x6 1x 9 Installation 1003 ...

Page 1023: ...Installation Procedure Preparation 1 4x 2 1x 1x 3 2x 9 Installation 1010 ...

Page 1029: ...4 5 1x 1x 9 Installation 1016 ...

Page 1048: ...3 2x TP M3x8 Black 4 2x TP M3x6 5 9 Installation 1035 ...

Page 1053: ... Installing the Removable HDD Kit 1 2x 2x 2 3 1x 4 9 Installation 1040 ...

Page 1065: ...3 2x TP M3x8 Black 4 2x TP M3x6 5 9 Installation 1052 ...

Page 1071: ... Installing the Removable HDD Kit 1 2x 2x 2 3 1x 4 9 Installation 1058 ...