Symbol

Name

Role

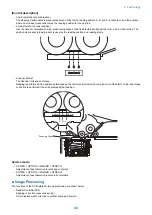

SL2

Stamp solenoid

Stamps on a document.

CL1

Pickup clutch

Transmit the Pickup motor drive to the Pickup roller and the Feed

roller.

CL2

Registration clutch

Transmit the power of the Pickup motor to the Lower registration

roller.

Reader Assembly

■ Magnification Ratio

● Changing the Magnification Ratio in the Horizontal Scanning Direction

When using the reading mode of the reader / When using the ADF

Reading in the horizontal scanning direction is performed at 100% size. Changes to the magnification ratio are processed by the

Main Controller PCB.

● Changing the Magnification Ratio in the Vertical Scanning Direction

As the magnification change in vertical scanning direction, the following operation is performed according to original reading

method and difference in magnification.

1. Magnification change operation when using the reading mode of the reader

Data is processed by the Main Controller PCB according to the magnification ratio.

Example) In the case of reducing the magnification to 25%: Original reading speed of 260 mm/sec, original reduced to 25%

(1/4 size) by the Main Controller PCB

Example) In the case of 100%: Original reading speed of 260 mm/sec

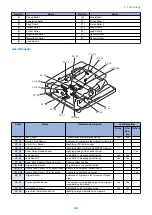

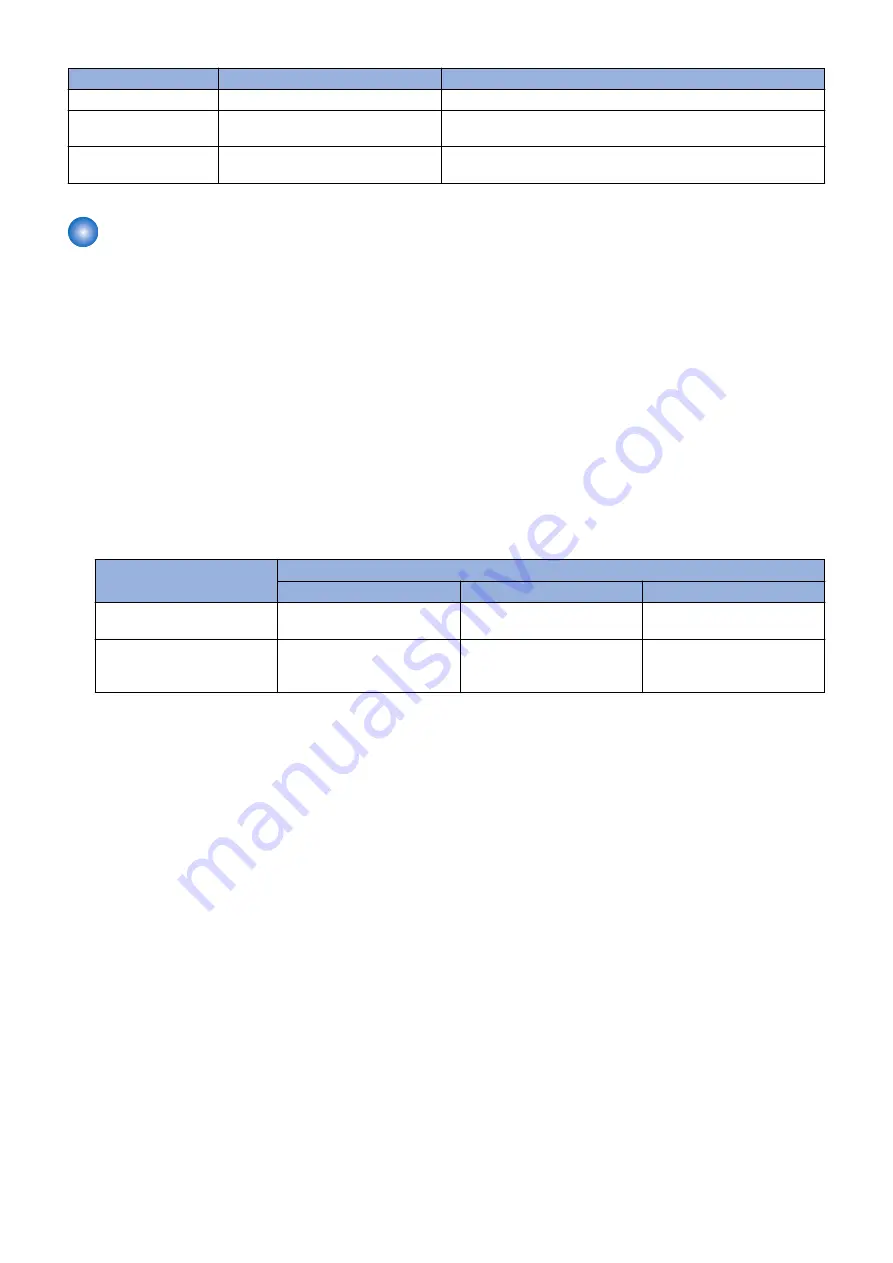

Operation description

Magnification

25 % to 50 %

50.1 % to 199.9 %

200 % to 400 %

Original reading speed (mm/

sec)

260

260

260

Digital magnification process-

ing in the Main Controller PCB

(%)

25 to 50

50.1 to 199.9

100 to 200

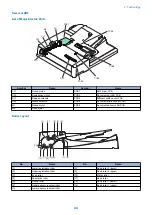

■ Original Size Detection

● Overview

This machine determines the size of an original by the combination of the measurement results of the reflected light at particular

points of the Reflection Sensor and Reading Sensor. Furthermore, two points are measured for each size to perform accurate

detection even if the original is moved when the ADF is closed.

• Horizontal scanning direction: Reading Sensor (AB configuration: 12 point measurement, inch configuration: 6 point

measurement)

• Vertical scanning direction: Reflection Photosensor (AB configuration, inch configuration: 1 location, AB/inch configuration:

1 location (shipped with position of Original Sensor 1, but can be changed the position of Original Sensor 2 as necessary))

The original size is determined using the following procedure:

1. Search of external light (horizontal scanning direction only)

The sensor level at each detection position in the horizontal scanning direction is measured while the LED is OFF.

2. Detection of output level of each sensor

The LED of the Reading Sensor Unit is turned ON to measure the sensor level at each detection position in the horizontal

scanning direction.

Furthermore, the Reflection Photo Sensor LED for the vertical scanning direction is turned ON to measure the sensor output.

The original size is determined by the combination of these outputs.

● Control description

In horizontal scanning direction, sensor level of each original detection position is measured by moving the Scanner Unit to the

detection position shown in the figure in relation to the original setting position. In the vertical scanning direction, the original size

is determined using the Original Sensor 1 and 2.

2. Technology

46

Summary of Contents for imagerunner advance 4551i

Page 19: ...Product Overview 1 Product Lineup 7 Features 13 Specifications 16 Name of Parts 26 ...

Page 155: ...Periodical Service 3 Consumable Parts List 143 Cleaning Check Adjustment Locations 146 ...

Page 392: ...Error Jam Alarm 7 Overview 380 Error Code 383 Jam Code 509 Alarm Code 520 ...

Page 545: ...Service Mode 8 Overview 533 COPIER 549 FEEDER 845 SORTER 851 BOARD 871 ...

Page 892: ...Unpacking 1 2 1200 mm 840 mm 769 mm 1230 mm 2430 mm 3 9 Installation 879 ...

Page 895: ...3 4 NOTE Keep the removed screws for relocating the host machine 2x 5 6 7 9 Installation 882 ...

Page 896: ...8 9 10 1x Installing the Air Filter 1 9 Installation 883 ...

Page 897: ...2 3 Installing the Drum Unit 1 2 3 9 Installation 884 ...

Page 899: ...8 NOTE The screw removed at procedure 4 is used 1x 9 10 11 12 9 Installation 886 ...

Page 923: ...5 6 NOTE Use the screws and Rubber Caps removed in step 1 2x 7 2x 9 Installation 910 ...

Page 935: ...7 1x 8 9 6x 10 2x 9 Installation 922 ...

Page 936: ...11 Installing the NFC Kit 1 2 2x 3 TP M3x4 1x 9 Installation 923 ...

Page 938: ...4 5 1x 6 9 Installation 925 ...

Page 985: ...8 2x 2x TP M4x8 Black When installing the USB Keyboard 1 9 Installation 972 ...

Page 991: ...7 4x 8 1x 1x Lower Cover 9 1x 10 1x 1x 9 Installation 978 ...

Page 992: ...11 1x 1x 12 1x 13 TP M3x12 2x 14 4x TP M3x6 9 Installation 979 ...

Page 997: ...Installation Procedure 1 2 2x 3 2x 4 6x 5 4x 9 Installation 984 ...

Page 998: ...6 7 NOTE Do not close the Wire Saddle 1x 1x 8 9 9 Installation 985 ...

Page 1003: ...2 1x 1x 3 2x 2x 4 9 Installation 990 ...

Page 1012: ...2 1x 1x 3 2x 2x 4 9 Installation 999 ...

Page 1014: ...7 CAUTION The connector must be contacted TP㸹M3x6 3x 1x 8 4x 9 9 Installation 1001 ...

Page 1016: ...13 4x 14 15 Binding M4x16 Binding M3x16 2x M3x16 M4x16 16 Binding M4x6 1x 9 Installation 1003 ...

Page 1023: ...Installation Procedure Preparation 1 4x 2 1x 1x 3 2x 9 Installation 1010 ...

Page 1029: ...4 5 1x 1x 9 Installation 1016 ...

Page 1048: ...3 2x TP M3x8 Black 4 2x TP M3x6 5 9 Installation 1035 ...

Page 1053: ... Installing the Removable HDD Kit 1 2x 2x 2 3 1x 4 9 Installation 1040 ...

Page 1065: ...3 2x TP M3x8 Black 4 2x TP M3x6 5 9 Installation 1052 ...

Page 1071: ... Installing the Removable HDD Kit 1 2x 2x 2 3 1x 4 9 Installation 1058 ...