Chapter 2

2-45

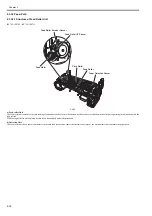

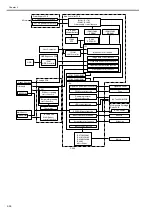

2.4.5 Power Supply

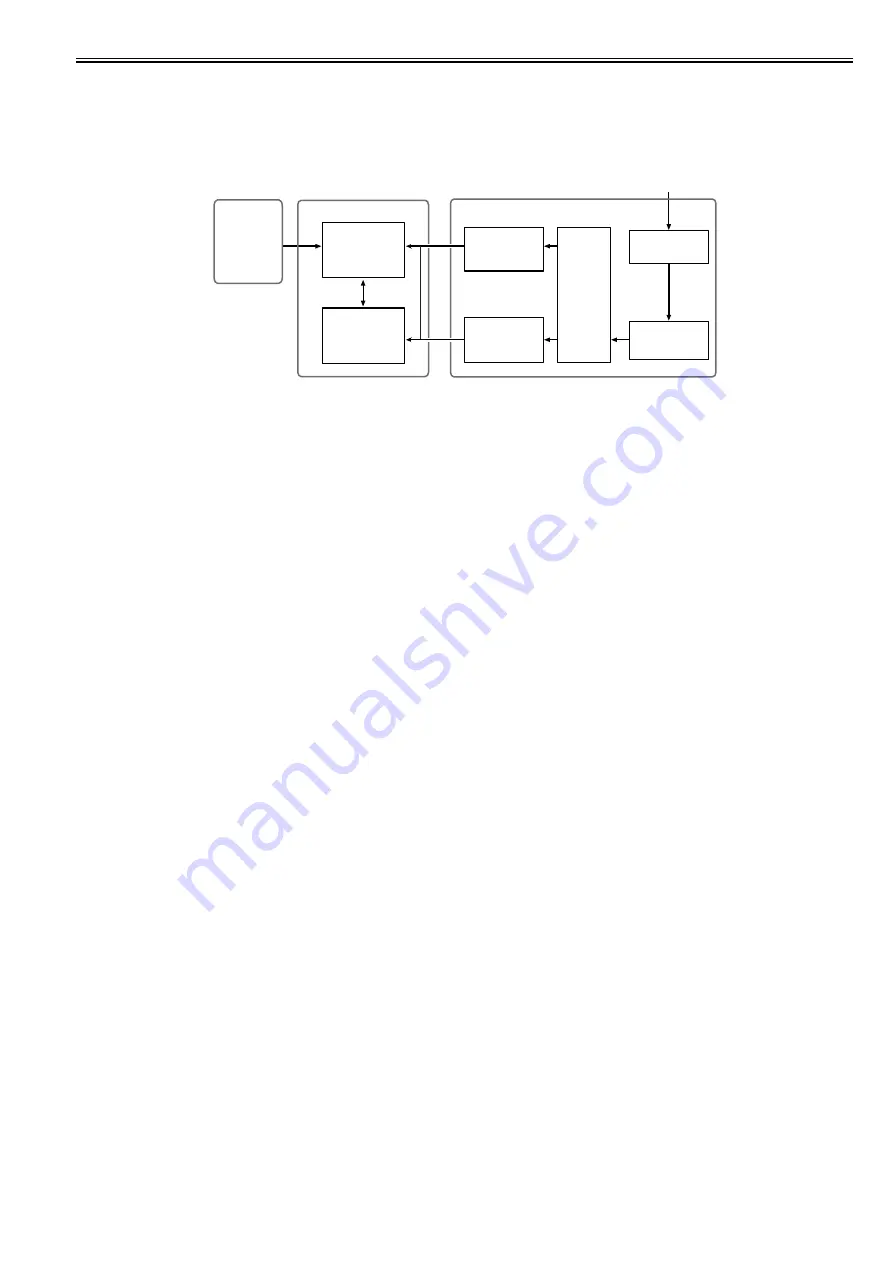

2.4.5.1 Power supply block diagram

0013-4333

iPF765 / iPF760 / iPF750 / iPF755

F-2-37

The power supply converts AC voltages ranging from 100 V to 240 V from the AC inlet to DC voltages for driving the ICs, motor, and others.

The voltage generator circuits include the +26 V generation circuit for driving motors, fans, and sensors and a +21.5 V generator circuit for driving sensors, heads,

logic circuits, and others.

When the power is turned off, +26 V and +21.5 V are reduced to about 12 V and 9 V respectively (power save mode).

Power ON/OFF operation is controlled by the main controller PCB.

Operation panel

Transformer

DC power supply

control circuit

+21.5V

generation circuit

+26V

generation circuit

POWER ON

Rectifying circuit

Noize filter circuit

AC inlet

100V to 240V

Power supply

Main controller PCB

+5V/+3.3V

generation circuit

Summary of Contents for iPF750 series

Page 1: ...Jul 25 2012 Service Manual iPF760 750 series ...

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Page 12: ......

Page 14: ...Contents 1 7 3 5 Self diagnostic Feature 1 71 1 7 3 6 Disposing of the Lithium Battery 1 72 ...

Page 87: ...Chapter 2 TECHNICAL REFERENCE ...

Page 88: ......

Page 99: ...Chapter 2 2 9 ...

Page 145: ...Chapter 3 INSTALLATION ...

Page 146: ......

Page 148: ......

Page 152: ......

Page 153: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Page 154: ......

Page 156: ......

Page 214: ...Chapter 4 4 58 2 Shaft Cleaner 1 F 4 119 1 ...

Page 215: ...Chapter 4 4 59 3 Upper Cover Hinge Catch 1 Roll Cover Slide Guide 2 F 4 120 2 1 ...

Page 218: ......

Page 219: ...Chapter 5 MAINTENANCE ...

Page 220: ......

Page 222: ......

Page 227: ...Chapter 5 5 5 ...

Page 228: ......

Page 229: ...Chapter 6 TROUBLESHOOTING ...

Page 230: ......

Page 232: ......

Page 250: ......

Page 251: ...Chapter 7 SERVICE MODE ...

Page 252: ......

Page 254: ......

Page 305: ......

Page 306: ......

Page 307: ...Chapter 8 ERROR CODE ...

Page 308: ......

Page 310: ......

Page 327: ...Jul 25 2012 ...

Page 328: ......