Chapter 2

2-21

2.3.2.3 Carriage Unit

2.3.2.3.1 Functions of Carriage Unit

0020-5488

iPF810 / iPF820

a) Printhead mounting function

The carriage, which fixes the printhead in position mechanically, is connected to the contact of the head relay PCB.

b) Control function

The carriage carries a carriage relay PCB, which relays drive signals from the main controller PCB, a head relay PCB,which relay printhead drive signals to print-

head, a linear encoder, which generates print timing signals, and a multi sensor, which detects the width of paper and skews in it, adjusts is registration and head

height.

The carriage relay PCB is connected to the main controller PCB by a flexible cable.

c) Carriage drive function

The carriage is caused to reciprocate level on the platen by means of the carriage belt that is driven by the power imparted from the carriage motor.

d) Printhead maintenance function

This printer performs cleaning operations, such as wiping the printhead and sucking inks, with the carriage halted at its home position.

e) Nozzle check function

This printer carries out an ink discharge operation with the carriage halted at the head management sensor, locating a non-discharging nozzle in the printhead.

f) Carriage height adjustment function

If the separation between the face of the printhead and the paper (carriage height) is varied as a result of differing paper thicknesses, cockled or curled paper or other

problems, the printer is liable to mist generation as the carriage height increases or to head rubbing as the carriage height decreases.

To maintain an acceptable carriage height, the lift motor is driven according to the selected paper type, feeding method, print conditions (borderless printing/prior-

itized picture quality) , environmental condition(temperature/humidity) and multi sensor measurements to automatically adjust the separation between the face of

the printhead and the paper

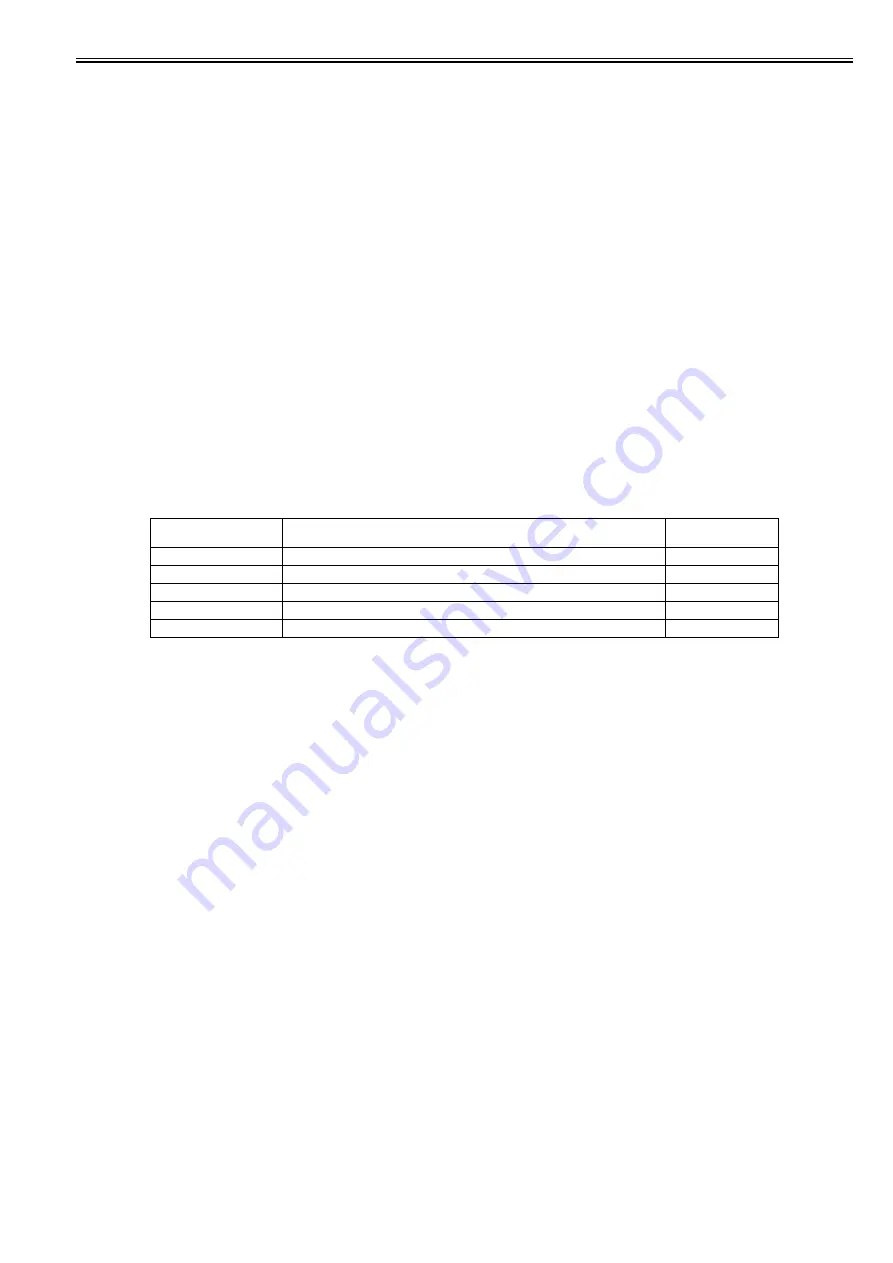

The table below shows the relation between the form kind and the height of the head.

T-2-5

g) Paper leading edge detection function/paper width detection function/skew detection function

The multi sensor attached to the lower left part of the carriage detects the leading edge and width of paper feeding on the platen and skews in it.

h) Automatic printhead position adjustment function

The multi sensor attached to the lower left part of the carriage reads an adjustment pattern printed on a form and adjusts the print timing of each printhead automat-

ically.

i) Remaining roll media detection function

The printer prints a bar code on roll media upon delivery. The multi sensor attached to the lower left part of the carriage indicates the remaining volume of roll media.

j) Internal unit temperature sensor

A thermistor installed on the head relay PCB detects the internal unit temperature near the printhead.

Height of printhead

(mm)

Media type

Remarks

1.3 (Lowest)

Photopaper, Synthetic paper, Film, Plain paper(Line drawing)

Capping position

1.8 (Low)

Coated paper(Line drawing)

2.0 (Standard)

Plain paper, Coated paper, Fabric banner

2.2 (High)

Premium matte paper, Fine art(watercolor,block print)

2.6 (Highest)

Canvas

Summary of Contents for iPF800 Series

Page 1: ...Aug 13 2008 Service Manual iPF800 series ...

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Page 12: ......

Page 14: ......

Page 38: ...Chapter 1 1 24 Hold this lever to pull out the lower roll unit ...

Page 100: ...Chapter 1 1 86 ...

Page 101: ...Chapter 2 TECHNICAL REFERENCE ...

Page 102: ......

Page 158: ......

Page 159: ...Chapter 3 INSTALLATION ...

Page 160: ......

Page 162: ......

Page 176: ...Chapter 3 3 14 ...

Page 177: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Page 178: ......

Page 180: ......

Page 238: ...Chapter 4 4 58 ...

Page 239: ...Chapter 5 MAINTENANCE ...

Page 240: ......

Page 242: ......

Page 246: ...Chapter 5 5 4 5 Close upper cover 1 F 5 6 1 ...

Page 247: ...Chapter 5 5 5 ...

Page 248: ......

Page 249: ...Chapter 6 TROUBLESHOOTING ...

Page 250: ......

Page 252: ......

Page 274: ......

Page 275: ...Chapter 7 SERVICE MODE ...

Page 276: ......

Page 278: ......

Page 301: ......

Page 302: ......

Page 303: ...Chapter 8 ERROR CODE ...

Page 304: ......

Page 306: ......

Page 318: ...Chapter 8 8 12 ...

Page 319: ...Aug 13 2008 ...

Page 320: ......