Chapter 2

2-23

thereby varying the separation between the face of the printhead and the paper.

The printhead height is detected from the lift cam sensor within the carriage and the distance of rotation of the lift motor.

g) Multi sensor

The multi sensor attached to the lower left part of the carriage consists of four LEDs (red, blue, green, infrared) and two light-receiving sensors to detect the leading

edges and width of paper and skews in it, and to adjust its registration and head height.

The multi sensor reference has a white plate attached to it, so that a reference value can be calculated during carriage height measurement by measuring the intensity

of light reflected upon the white plate.

(Service mode: SERVICE MODE>ADJUST>GAP CALIB.)

h) Rail cleaner

The shaft cleaner located in the right side of the carriage helps keep the main rail clean.

i) Internal unit temperature sensor

One thermistor is installed on the head relay PCB on the back of the head holder to detect the internal unit temperature.

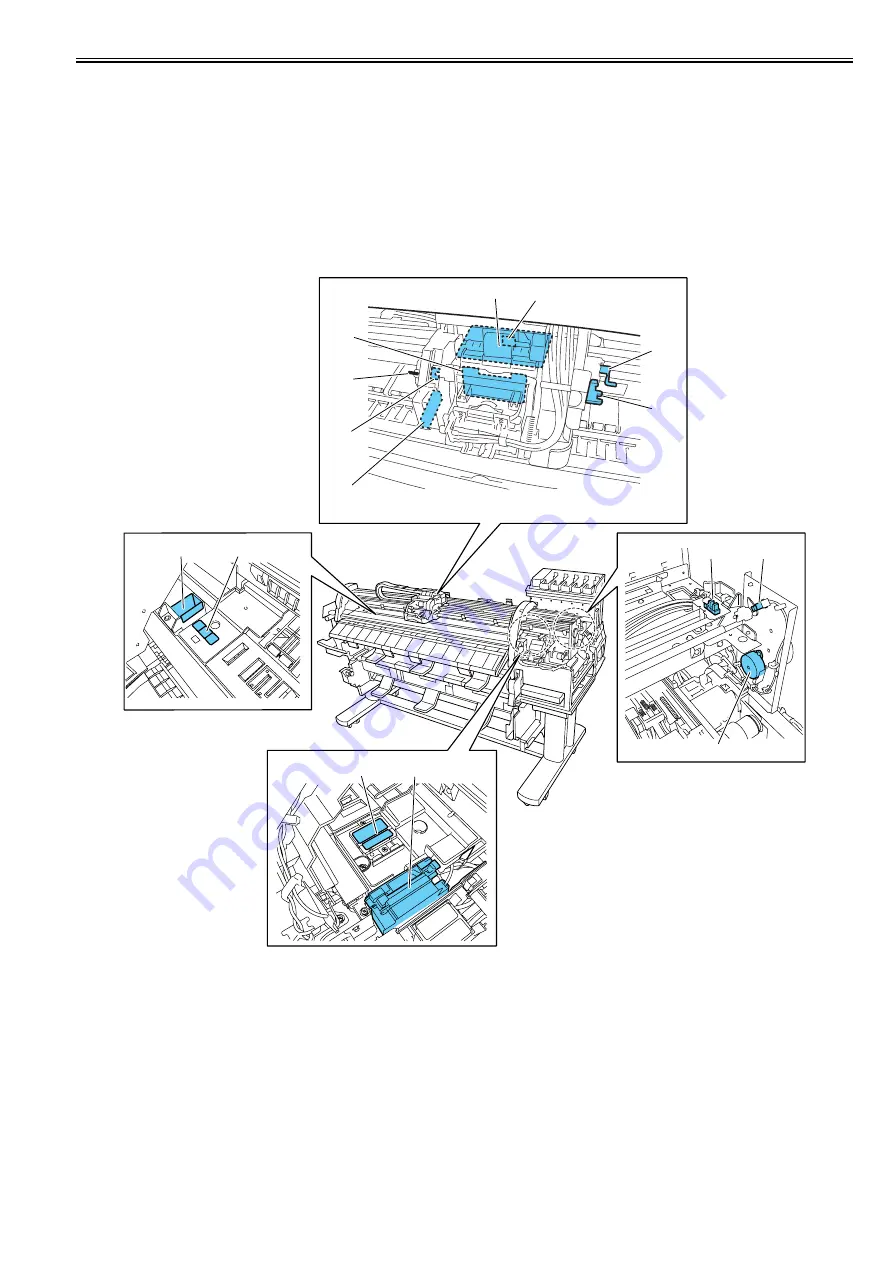

F-2-13

T-2-7

[1]

Carriage relay PCB

[9]

Multi sensor reference plate

[2]

Head relay PCB

[10] BP maintenance jet tray

[3]

Slant adjustment lever

[11] HP maintenance jet tray

[4]

Printhead fixer lever sensor

[12] Head management sensor

[5]

Multi sensor

[13] Carriage HP sensor

[6]

Shaft cleaner

[14] Lift cam sensor

[7]

Lift cam

[15] Lift motor

[8]

Linear encoder

[13]

[14]

[11]

[12]

[14]

[10]

[9]

[1]

[7]

[6]

[2]

[3]

[4]

[5]

[8]

Summary of Contents for iPF800 Series

Page 1: ...Aug 13 2008 Service Manual iPF800 series ...

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Page 12: ......

Page 14: ......

Page 38: ...Chapter 1 1 24 Hold this lever to pull out the lower roll unit ...

Page 100: ...Chapter 1 1 86 ...

Page 101: ...Chapter 2 TECHNICAL REFERENCE ...

Page 102: ......

Page 158: ......

Page 159: ...Chapter 3 INSTALLATION ...

Page 160: ......

Page 162: ......

Page 176: ...Chapter 3 3 14 ...

Page 177: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Page 178: ......

Page 180: ......

Page 238: ...Chapter 4 4 58 ...

Page 239: ...Chapter 5 MAINTENANCE ...

Page 240: ......

Page 242: ......

Page 246: ...Chapter 5 5 4 5 Close upper cover 1 F 5 6 1 ...

Page 247: ...Chapter 5 5 5 ...

Page 248: ......

Page 249: ...Chapter 6 TROUBLESHOOTING ...

Page 250: ......

Page 252: ......

Page 274: ......

Page 275: ...Chapter 7 SERVICE MODE ...

Page 276: ......

Page 278: ......

Page 301: ......

Page 302: ......

Page 303: ...Chapter 8 ERROR CODE ...

Page 304: ......

Page 306: ......

Page 318: ...Chapter 8 8 12 ...

Page 319: ...Aug 13 2008 ...

Page 320: ......