Summary of Contents for iPF800 Series

Page 1: ...Aug 13 2008 Service Manual iPF800 series ...

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Page 12: ......

Page 14: ......

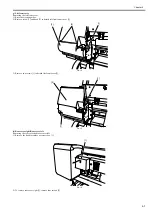

Page 38: ...Chapter 1 1 24 Hold this lever to pull out the lower roll unit ...

Page 100: ...Chapter 1 1 86 ...

Page 101: ...Chapter 2 TECHNICAL REFERENCE ...

Page 102: ......

Page 158: ......

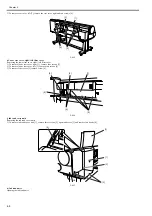

Page 159: ...Chapter 3 INSTALLATION ...

Page 160: ......

Page 162: ......

Page 176: ...Chapter 3 3 14 ...

Page 177: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Page 178: ......

Page 180: ......

Page 238: ...Chapter 4 4 58 ...

Page 239: ...Chapter 5 MAINTENANCE ...

Page 240: ......

Page 242: ......

Page 246: ...Chapter 5 5 4 5 Close upper cover 1 F 5 6 1 ...

Page 247: ...Chapter 5 5 5 ...

Page 248: ......

Page 249: ...Chapter 6 TROUBLESHOOTING ...

Page 250: ......

Page 252: ......

Page 274: ......

Page 275: ...Chapter 7 SERVICE MODE ...

Page 276: ......

Page 278: ......

Page 301: ......

Page 302: ......

Page 303: ...Chapter 8 ERROR CODE ...

Page 304: ......

Page 306: ......

Page 318: ...Chapter 8 8 12 ...

Page 319: ...Aug 13 2008 ...

Page 320: ......