Chapter 7

7-25

COPIER > ADJUST > LASER >FSLUT-C 1 to 8 correction values for partial magnification correction Y blocks 1 to 8

COPIER > ADJUST > LASER >FSLUT-K 1 to 8 correction values for partial magnification correction K blocks 1 to 8

Also, when the DC controller circuit board is replaced, the above values should be entered as per the details on the service label or on the P-PRINT label.

7.3.10 ATVC Control

0013-8495

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

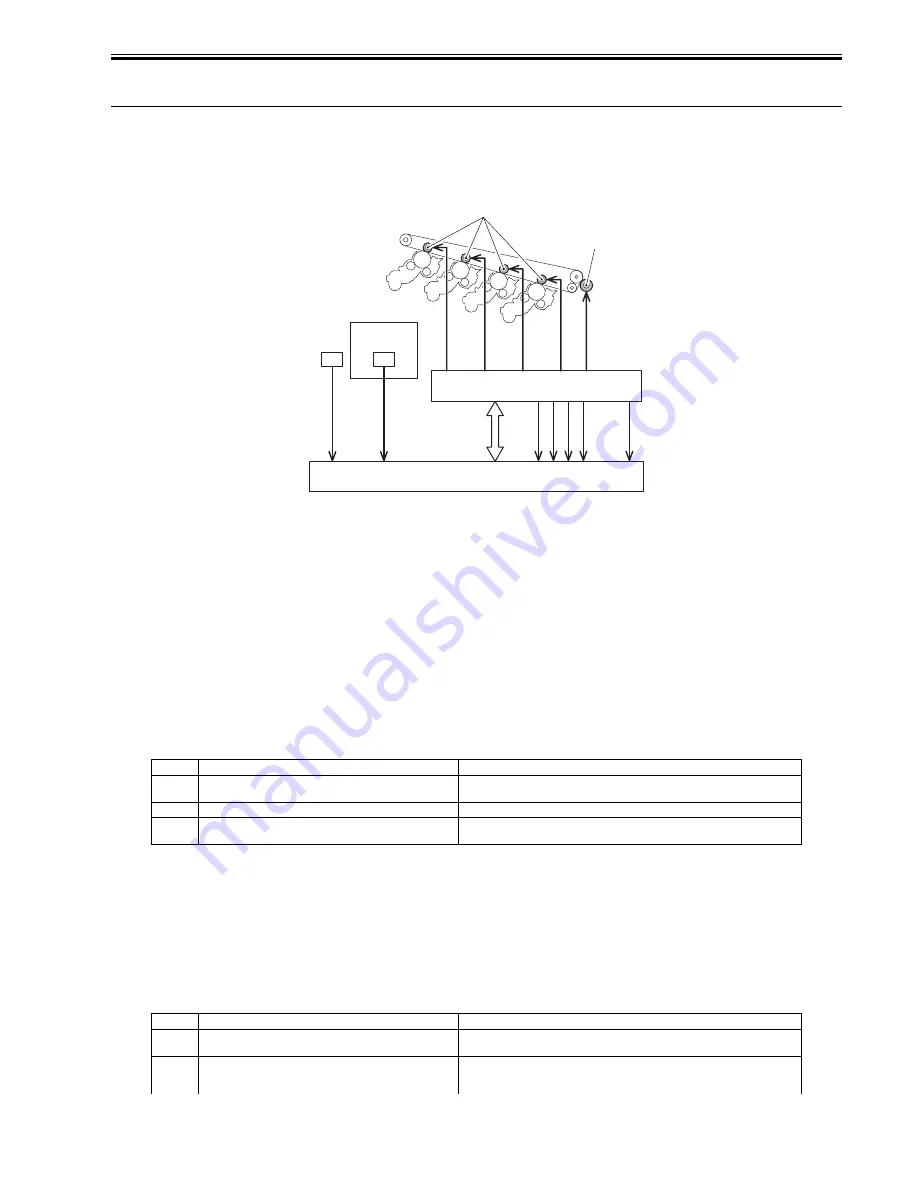

In the case of transferring toner, this control has 2 types of controls: the primary transfer ATVC and the secondary transfer ATVC, to decide the most suitable

transfer bias.

F-7-34

[1] Primary transfer roller

[2] Secondary transfer outside roller

[3] Machine inside environment sensor

[4] Machine outside environment sensor

1. Primary Transfer ATVC

The machine executes primary transfer ATVC when determining the primary transfer bias used to ensure the target transfer current level for transfer.

a. Timing for start-up

- when the power is ON

- during warm-up rotation

- in the case of continuous passage of paper, when the accumulated value is 200 prints from the last time ATVC execution.

- comparing from the last time ATVC execution, the initial rotation when the inside humidity is 10% or more, or when the change of humidity is 2 deg C or more.

- comparing from the last time ATVC execution, the next initial rotation of post accumulating 100 prints.

- immediately before D-half

- warm-up rotation in the case of sleep return of 8 hours or more.

- When new drum unit is installed.

b. Particulars of Control

T-7-12

2. Secondary Transfer ATVC

The machine executes secondary transfer ATVC when determining the secondary transfer bias so that the target transfer current may be obtained for transfer.

a. Start-Up Conditions

- at power-on

- when the drum unit is replaced with a new one

- during initial rotation

- during post-rotation executed every 1000 prints

- during recovery from sleep

- during execution of calibration

b. Particulars of Control

T-7-13

Sequence

Item

Description

1

Applying the primary transfer bias

A specific bias is applied to the primary transfer roller, and HVT2 is used to detect the

level of current for feedback to the DC controller.

2

Monitoring the machine inside environment sensor

The DC controller monitors the output of the machine inside environment sensor.

3

Determining the primary transfer bias

The DC controller determines the best primary transfer bias for individual colors based

on the foregoing 3 sets of data.

Sequence

Item

Description

1

Applying the secondary transfer bias

A specific bias is applied to the secondary transfer roller, and HVT2 is used to detect

the level of current for feedback to the DC controller.

2

Monitoring the machine outside environment sensor

The DC controller computes the secondary transfer bias correction value with

reference to the output of the compensatory environment sensor (i.e., the degree of

moisture in paper) and print job information (i.e., paper type, 1st/2nd side).

D-CON

HVT2

[3]

[1]

[4]

[2]

TR1S_Y

R

OOM_TEMP1

R

OOM_TEMP2

TR1S_M

TR1S_C

TR1S_BK

TR2S

Laser Scanner Unit

Summary of Contents for iR C3380 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Page 189: ...Chapter 6 Laser Exposure...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Page 337: ...Chapter 10 10 11 F 10 11...

Page 359: ...Chapter 11 MEAP...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Page 421: ...Chapter 14 Standards and Adjustments...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006...

Page 610: ......