Chapter 8

8-14

8.4.3 Other Jams

8.4.3.1 Size Difference Jam

0013-8629

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

In the case of detecting paper that is shorter than specified

8.4.3.2 Material Difference Jam

0013-8630

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

In the case that the transparency sensor detects paper that is different from the specified.

8.4.3.3 Door Open Jam

0014-0312

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

A door open jam is identified when the machine detects the opening of the door while it is making copies/prints.

8.5 Cassette Pick-Up Unit

8.5.1 Overview

0014-0313

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

The paper inside the cassette is held up by the lifter plate. When pickup takes place, the pickup roller moves down to come into contact with the surface of paper.

The pickup roller is moved down when the pickup solenoid goes on.

The feed roller and the separation roller serve to make sure that a single sheet of paper is moved to the feed path, and the paper is moved as far as the registration

roller by the work of the vertical path roller.

The pickup vertical path roller, pickup roller, feed roller, and separation roller are driven by the cassette pickup motor.

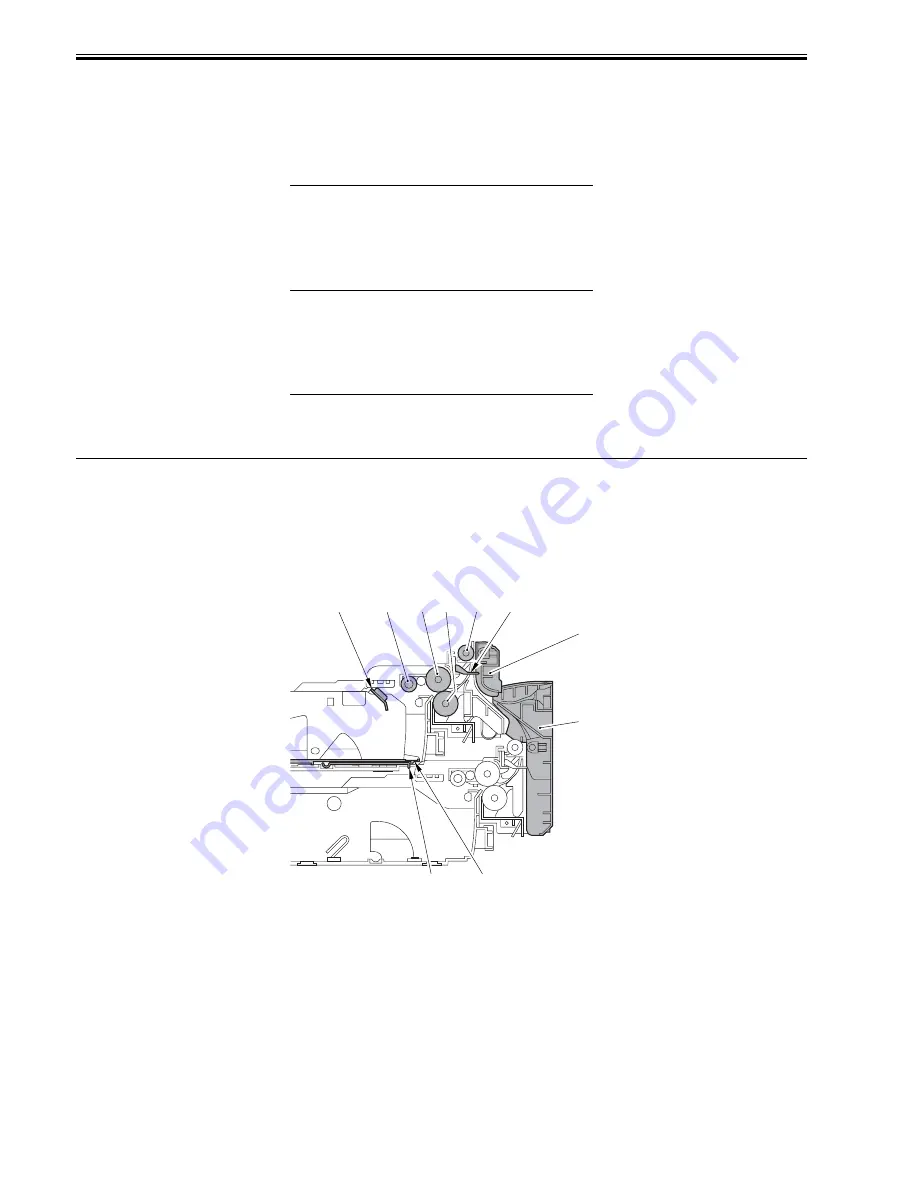

F-8-16

[1] Cassette paper sensor

[2] Pickup roller

[3] Feed roller

[4] Separation roller

[5] Pickup vertical path roller

[6] Cassette retry paper sensor

[7] Vertical path guide

[8] Lower right cover

[9] Holding plate

[10] Lifter plate

Sensor

Pre-registration sensor (PS7)

Sensor

Transparency sensor PCB (UN18, UN19)

Sensor

Front cover open sensor (PS17)

Right cover open sensor (PS19)

[9]

[10]

[7]

[8]

[1]

[2]

[3]

[4]

[5]

[6]

Summary of Contents for iR C3380 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Page 189: ...Chapter 6 Laser Exposure...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Page 337: ...Chapter 10 10 11 F 10 11...

Page 359: ...Chapter 11 MEAP...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Page 421: ...Chapter 14 Standards and Adjustments...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006...

Page 610: ......