Chapter 9

9-8

9.2.2 Down Sequence Control

9.2.2.1 Down Sequence Control

0014-5555

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

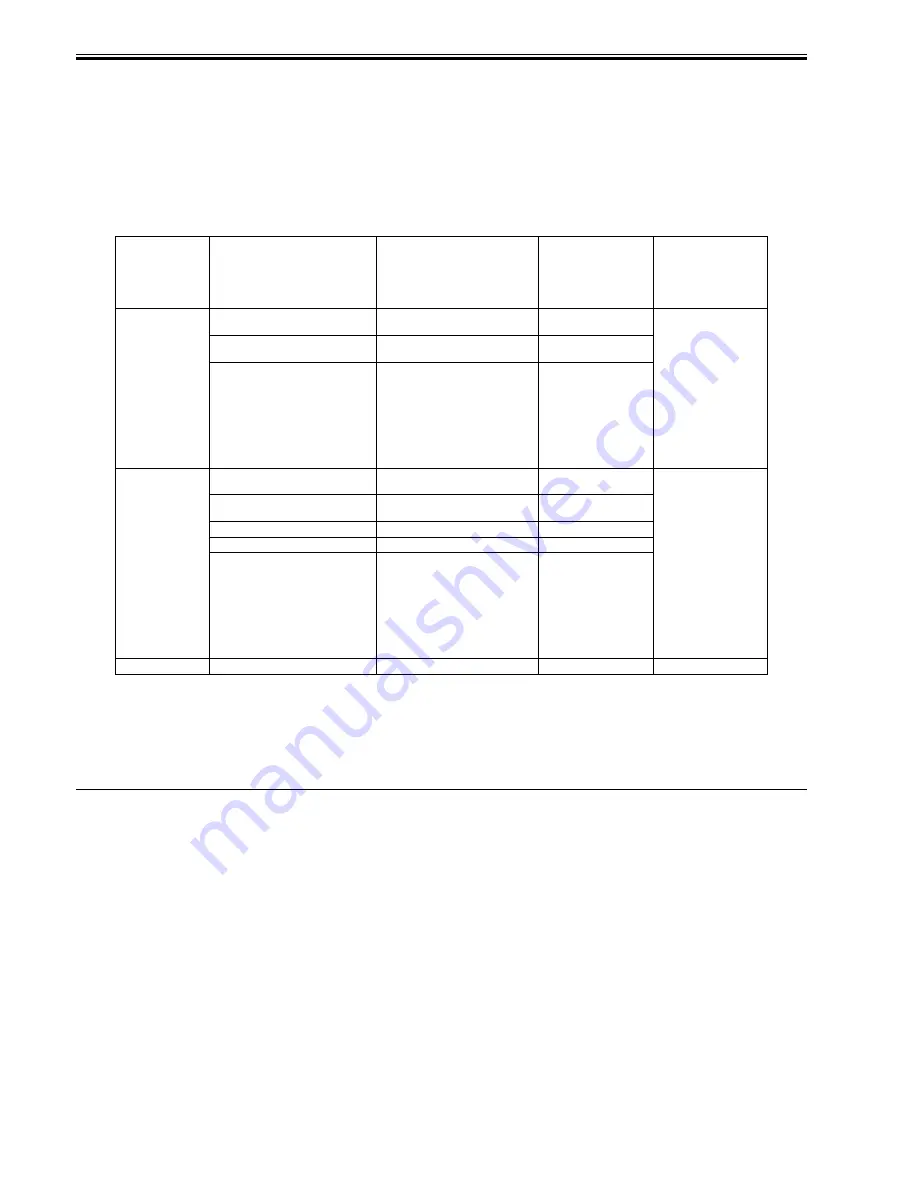

This equipment runs down-sequence control in the cases listed below. Down-sequence control decreases the print speed by lengthening the interval between sheets

in order to prevent film deterioration caused by heated edge of the fixing film during continuous printing of small-sized (smaller than A4R) paper.

- When the sub-thermistor 1 temperature reading exceeds the readings listed below

- When the sub-thermistor 2 temperature reading exceeds 220 degrees C

Also in the case of uncertain paper size (e.g., by manual feeding or unspecified paper size) it executes the down sequence control as well as in the case of printing

small sized papers.

The following table indicates the down sequences in accordance with the paper type).

T-9-10

*1 rough paper: heavy paper (106 to 169 g/m2), bond paper (64 to 105 g/m2), coated paper (106 to 169 g/m2), label paper.

*2 extra heavy paper (170 to 220 g/m2), extra heavy coated paper (170 to 20 g/m2), Jpn postcard, 2-pane Jpn postcard, 4-pane Japan postcard, envelope.

*3 For settings and details of special fixing mode 2, see the User's Guide.

In the case of continuous print of the small size paper (the width less than A4R), it executes fixing film edge cooling control to prevent film deterioration caused

by heating of the fixing film edge, as opposed to the down sequence.

9.3 Film Unit Pressurizing Mechanism

9.3.1 Pressure/release control

0014-6432

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

This machine does the control to make pressuring/releasing the fixing film unit to prevent the fixing film being transformed.

Pressuring/releasing of fixing film unit are regulated by pressure plate [1] and releasing lever [2]. Pressure plate [1] pushes fixing film unit [4] by a spring to press

it to pressure roller [5]. Release lever [2] is rotated by fixing motor (M3), pushes pressure plate [1] down to release fixing film unit [4] from pressure roller [5].

pressuring operation

Fixing motor (M3) rotates in a positive direction. The pressure plate [1] puts down the fixing film unit by the power of the spring and presses to the pressure roller

[5].

releasing operation

Fixing motor (M3) reverses, pressure release lever 2 [2] pushes up the pressure plate [2] so that the fixing film unit [4] releases from the pressure roller [5].

Process speed

Paper type

User setting

Sub-Thermistor 1

Temperature (Reading at

Ambient Temperature

and Humidity / Low

Temperature and

Humidity)

Printing speed (ppm)

Normal speed

plain paper

(64 to 105 g/m2)

plain paper

220/225

30 to 4

thin paper

(less than 64 g/m2)

plain paper L

210/215

special fixing mode 2 *3

LBP3380

special printing process

>plain paper

>mode 2

LBP2880

process option

>special fixing mode

>mode 2

235/240

half-speed

plain paper

(64 to 105 g/m2)

plain paper

190/200

15 to 2

thin paper

(less than 64 g/m2)

plain paper L

180/190

rough paper *1

heavy paper 1

205/215

rough paper (strong) *2

heavy paper 2

220/225

special fixing mode 2 *3

LBP3380

special printing process

>plain paper

>mode 2

LBP2880

processing option

>special fixing mode

>mode 2

200/205

1/4 Speed

OHT

OHT

180/185

7 to 2

Summary of Contents for iR C3380 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Page 189: ...Chapter 6 Laser Exposure...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Page 337: ...Chapter 10 10 11 F 10 11...

Page 359: ...Chapter 11 MEAP...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Page 421: ...Chapter 14 Standards and Adjustments...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006...

Page 610: ......