Chapter 14

14-2

F-14-5

d. service label (behind reader unit left cover) values

d-1. CIS read position adjustment (fixed reading)

COPIER>ADJUST>ADJ-XY>ADJ-X

d-2. main scanning direction position adjustment (fixed reading)

COPIER>ADJUST>ADJ-XY>ADJ-Y

d-3. shading position adjustment (fixed reading)

COPIER>ADJUST>ADJ-XY>ADJ-S

d-4. sub scanning direction color displacement correction

COPIER>ADJUST>CCD>CCDU-RG

d-5. main/sub scanning direction MTF value

COPIER>ADJUST>CCD>MTF-MG,SG

d-6. auto gradation correction target value

COPIER>ADJUST>PASCAL>OFST-P-Y,M,C,K

If the value of the following was not 0 before the replacement of the

reader controller PCB: COPIER>OPTION>BODY>CCD-LUT.

Set a value other than '0' once again, and make the following adjustments

using the D-10 Chart.

COPIER>FUNCTION>CCD>LUT-ADJ2

2. ADF-Related Adjustment

The machine keeps ADF-related service mode data in the RAM of the

reader controller; as such, you will have to make the appropriate

adjustments if you have replaced the reader controller or initialized the

RAM.

1) Enter the values indicated in the P-PRINT printout you have previously

generated for the following:

a. main scanning direction position adjustment (stream reading)

COPIER>ADJSUT>ADJ-XY>ADJ-Y-DF

b. original stop position adjustment

FEEDER>ADJSUT>DOCST

c. original feed speed (magnification) adjustment

FEEDER>ADUST>LA-SPEED

2) Make adjustments using the following items:

a. tray width adjustment

FEEDER>FUNCTION>TRY-A4

FEEDER>FUNCTION>TRY-A5R

FEEDER>FUNCTION>TRY-LTR

FEEDER>FUNCTION>TRY-LTRR

b. CIS read position adjustment (stream reading)

COPIER>FUNCTION>INSTALL>STRD-POS

c. white level adjustment

COPIER>FUNCTION>CCD>DF-WLVL1

COPIER>FUNCTION>CCD>DF-WLVL2

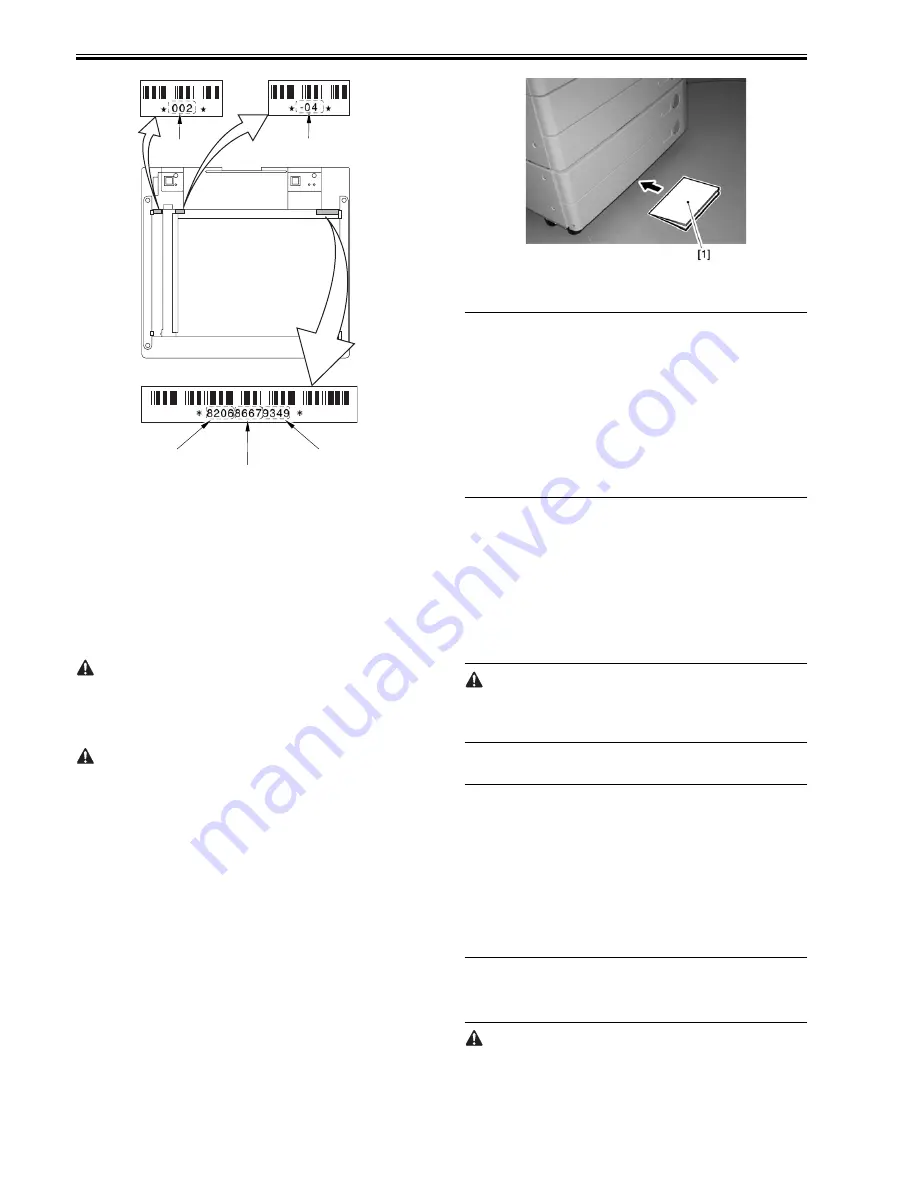

When you have finished the foregoing adjustments, put the P-PRINT print-

out [1] you have previously generated in the service book cassette to replace

the old P-PRINT printout.

F-14-6

14.2 Laser Exposure System

14.2.1 After Replacing the Laser Scanner Unit

0014-3098

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

When replacing the laser scanner unit, register the values described on the

label which is included in the package in the service modes below. After reg-

istration, attach the label onto the front cover.

COPIER > FUNCTION > LASER > FSLUT-Y1 to 8

COPIER > FUNCTION > LASER > FSLUT-M1 to 8

COPIER > FUNCTION > LASER > FSLUT-C1 to 8

COPIER > FUNCTION > LASER > FSLUT-K1 to 8

Registration of the main scanner reproduction ratio correction value

14.3 Image Formation System

14.3.1 After Replacing the Secondary Transfer Roller

0014-3128

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

Upon replacement to the new secondary transfer outer roller, attachment of

the rubber component of the secondary transfer roller onto the ITB belt caus-

es a white spot image.

In order to prevent this, at replacing the secondary transfer outer roller to the

new one, coating of toner onto the surface of the roller is required.

When replacing the secondary transfer outer roller, execute the service mode

below:

- COPIER > FUNCTION > TNR-COAT

Coating of the Y toner onto the secondary transfer roller

In case the white spot image occurred after replacing the secondary transfer

roller, clean the ITB unit.

Initial settings / registration > adjustment / cleaning > cleaning within the

main body

14.4 Fixing System

14.4.1 Confirming of the nip width

0014-3631

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

Executed the following item of the service mode, and measure the nip width.

COPIER>FUNCTION>FIXING>NIP-CHK

*:The sheet stops temporarily at the fixing unit and it is delivered.

Standard of the nip width

Center part: 8mm or more

Difference of right and left edge: 1mm or less

14.5 Electrical Components

14.5.1 After Replacing the Reader Controller PCB

0014-3118

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

- Before replacing the reader controller PCB, be sure to generate the latest P-

PRINT printout.

- If you carry out the power ON and the copier returns to the standby

condition after the controller circuit PCB replacement, turn ON/OFF the

power supply once again.

W- P LT- X

W- P LT- Y

W- P LT- Z

D F - R G

B O O K - R G

Summary of Contents for iR C3380 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Page 189: ...Chapter 6 Laser Exposure...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Page 337: ...Chapter 10 10 11 F 10 11...

Page 359: ...Chapter 11 MEAP...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Page 421: ...Chapter 14 Standards and Adjustments...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006...

Page 610: ......