Chapter 17

17-16

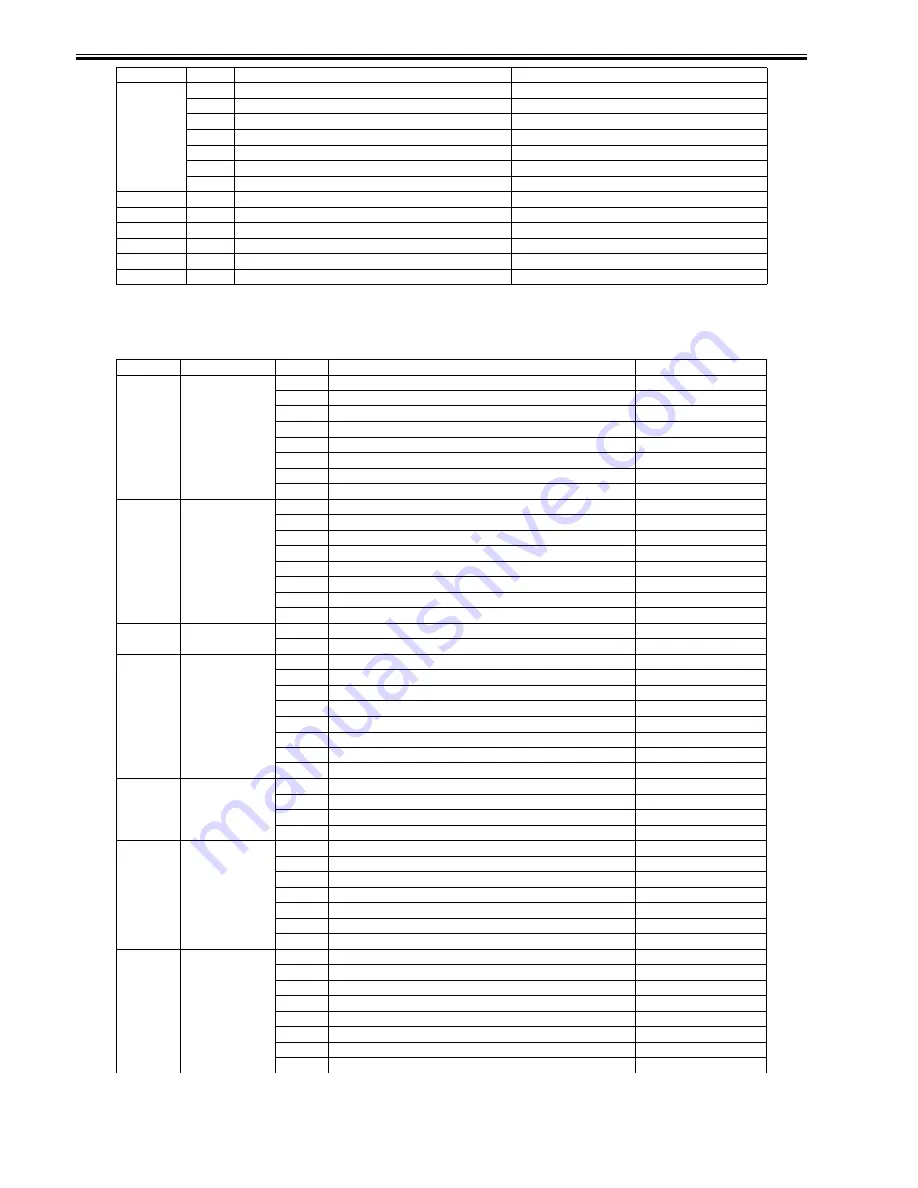

17.3.5 <SORTER>

0014-6641

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

T-17-21

P005

0

cycle end sensor

1: detected

1

length sensor 2

1: detected

2

length sensor 1

1: detected

3

A4/LTR identification sensor

1: detected

4,5

not used

6

delivery sensor

0: detected

7

DF open sensor

1: detected

P006

0-7

for R&D

P007

0-7

for R&D

P008

0-7

for R&D

P009

0-7

for R&D

P010

0-7

for R&D

P011

0-7

for R&D

Address

Controller

Bit

Description

Remarks

P001

SORTER

0

inlet feed motor A

1

inlet feed motor B

2

inlet feed motor A-

3

inlet feed motor B-

4

inlet feed motor switch 0

0: ON

5

inlet feed motor switch 1

0: ON

6

inlet feed/stack delivery motor standby signal

1: ON

7

common solenoid ON signal

0: ON

P002

SORTER

0

punch feed motor A

1

punch feed motor A-

2

punch feed motor B

3

punch feed motor B-

4

punch feed motor current switch 0

1: ON

5

punch feed motor current switch 1

1: ON

6

tray 2 motor clock

7

tray 1 motor clock

P003

SORTER

0-3

for R&D

4-7

not used

P004

SORTER

0

saddle connection detection signal

0: ON

1

not used

2

swing HP sensor

1: ON

3

upper cover open/closed sensor

0: ON

4

front cover open/closed sensor

0: ON

5

front cover interlock sensor

1: ON

6

gear change HP sensor

1: ON

7

not used

P005

SORTER

0,1

for R&D

2

punch transmission request signal

0: ON

3

saddle 13V ON signal

1: ON

4-7

not used

P006

SORTER

0

punch connection detection

0: ON

1,2

not used

3

punch motor standby

1: ON

4

inlet sensor (IRQ0)

1: ON

5

paper trailing edge sensor (IRQ1)

1: ON

6

punch communication input (IRQ2)

0: ON

7

not used

P007

SORTER

0

tray approach sensor

0: ON

1

tray 2 area sensor 1

0: ON

2

tray 2 area sensor 2

0: ON

3

tray 2 area sensor 3

0: ON

4

tray 2 paper sensor

1: ON

5

tray 2 paper surface sensor

1: ON

6

inlet motor lock sensor

7

stack edging motor lock input

Address

Bit

Description

Remarks

Summary of Contents for iR C3380 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Page 189: ...Chapter 6 Laser Exposure...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Page 337: ...Chapter 10 10 11 F 10 11...

Page 359: ...Chapter 11 MEAP...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Page 421: ...Chapter 14 Standards and Adjustments...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006...

Page 610: ......