Chapter 17

17-37

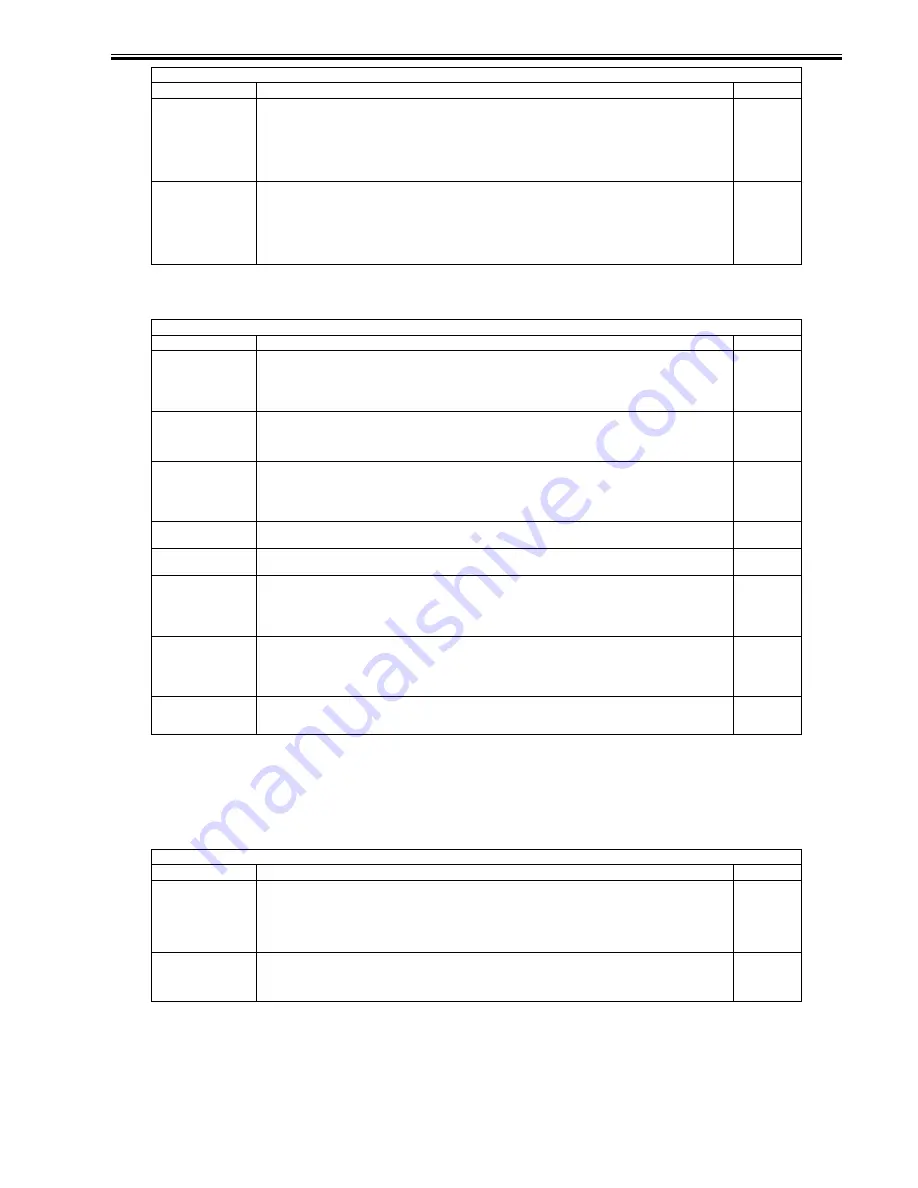

14. MISC

T-17-38

17.4.2 FEEDER

17.4.2.1 FEEDER Table

0013-8997

/ / / / iR C3380i / iR C3380 / iR C2880i / iR C2880

T-17-39

MF-A6R

Used to enter the basic value for the manual feed tray's paper width (A6R).

Adjustment method

- If you have cleared the DC controller PCB's RAM or replaced the DC controller PCB, enter the value on the service

label.

- When replacing the paper width detection VR or registering a new value, perform the following service mode:

FUNCTION>CST.

Adjustment range 0 to 255 [Factory default/After RAM clear: 235]

1

MF-A4

Used to enter the basic value for the manual feed tray's paper width (A4).

Adjustment method

- If you have cleared the DC controller PCB'sRAM or replaced the DC controller PCB, enter the value on the service

label.

- When replacing the paper width detection VR or registering a new value, perform the following service mode:

FUNCTION>CST.

Adjustment range 0 to 255 [Factory default/After RAM clear: 26]

1

COPIER>ADJUST>MISC

Sub item

Description

level.

SEG-ADJ

Used to adjust the text and photo separation level for text/photo/map mode.

Adjustment method

- To make documents more easily recognized as photo documents, increase the setting value.

- To make documents more easily recognized as text documents, decrease the setting value.

Adjustment range -4to 4 (Value at time of factory shipment/value after RAM clear: 0)

1

K-ADJ

Used to adjust the black recognition level during black text processing.

Adjustment method

- To make text more easily recognized as black, increase the setting value.

Adjustment range -3to 3 (Value at time of factory shipment/value after RAM clear: 0)

1

ACS-ADJ

Used to adjust the color recognition level during ACS mode.

Adjustment method

To make documents more easily recognized as black and white documents, increase the setting value.

- To make documents more easily recognized as color documents, decrease the setting value.

Adjustment range -3to 3 (Value at time of factory shipment/value after RAM clear: 0)

1

ACS-EN

- ACS-EN (Used to adjust ACS recognition zone.)

Increasing the setting value expands the recognition zone.

2

ACS-CNT

- ACS-CNT (Used to adjust color recognition pixel count zone during ACS recognition.)

Increasing the setting value expands the recognition zone.

2

ACS-EN2

ACS judgement area adjustment (with DF stream reading)

Adjustment method

Increasing the setting value increases the judgement range.

Setting range: -2 to 2

[Factory settings and after RAM clear: 1]

2

ACS-CNT2

Colour judgement pixel count area adjustment in ACS judgement (with DF stream reading)

Adjustment method

Increasing the setting value increases the judgement range.

Setting range: -2 to 2

[Factory settings and after RAM clear: 0]

2

REOS-PG

REOS processing coefficient selection in 1200 dpi

Setting range: 0 to 4

[Factory settings and after RAM clear: 0]

2

FEEDER>ADJUST

Sub item

Description

level.

DOCST

Adjusting the Original Image Leading Edge

Method of adjustment

A higher setting will delay the image leading edge timing.

Range of adjustment

-50 to 50 (unit: 0.1mm)

[Factory default/After RAM clear:0]

1

LA-SPEED

Adjusting the document feeding speed at the time of stream reading from the feeder

The speed becomes faster (image is reduced) by increasing setting value.

Range of adjustment: -30 to 30 (unit: 0.1%)

[Factory default/After RAM clear:0]

1

COPIER>ADJUST>CST-ADJ

Sub item

Description

level.

Summary of Contents for iR C3380 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Page 189: ...Chapter 6 Laser Exposure...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Page 337: ...Chapter 10 10 11 F 10 11...

Page 359: ...Chapter 11 MEAP...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Page 421: ...Chapter 14 Standards and Adjustments...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006...

Page 610: ......