Chapter 17

17-59

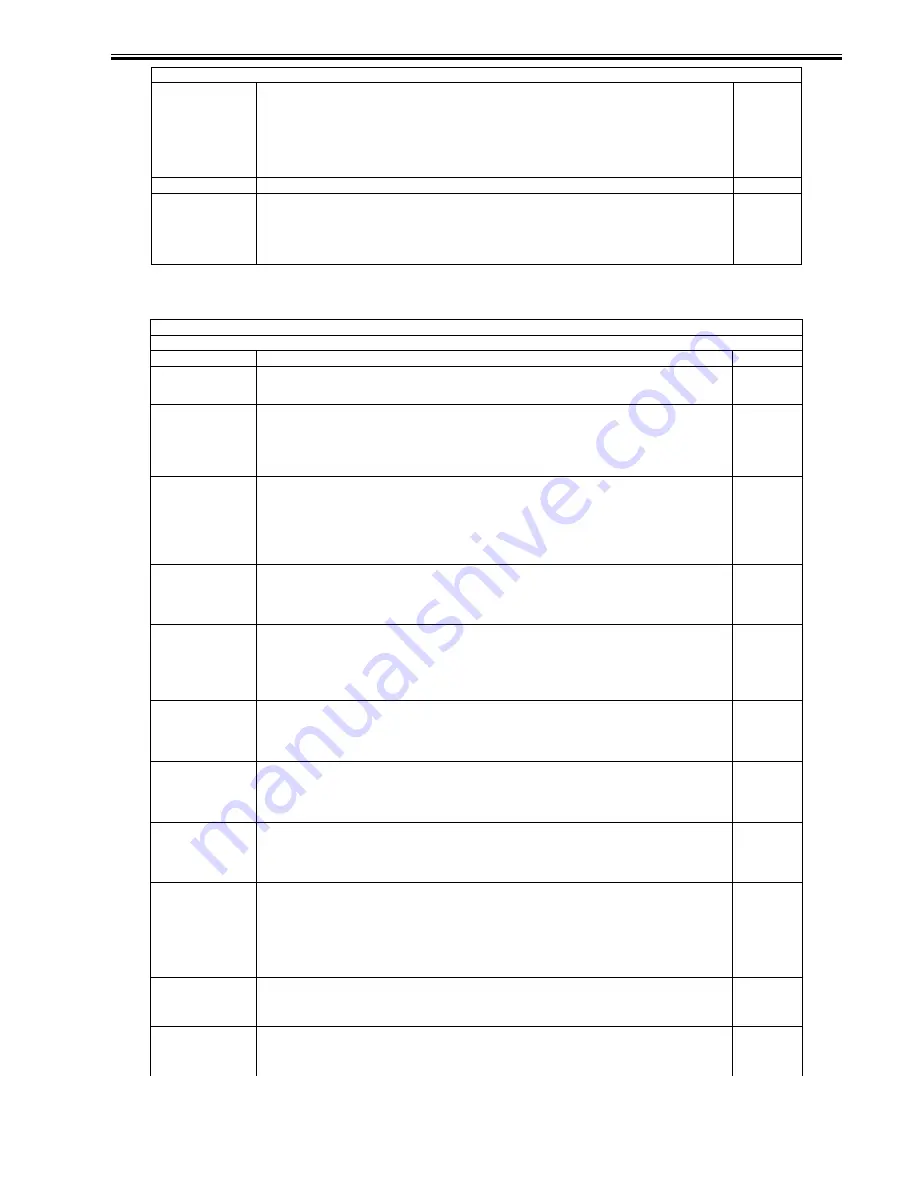

2. USER

T-17-55

FLYING

Setting whether to initiate a flying start

This is set to "1" when a flying start is not to be initiated in consideration of the service life of the fixing unit. Normally,

after a job is completed, operation is controlled so that the fixing is performed and the takes of the polygons are made

longer in preparation for the next job, but this control is not performed when the item is set to "1."

Settings

0: A flying start is initiated.

1: A flying start is not initiated.

[Factory setting/value after clearing RAM: 0]

2

PP-LWRT

Not used

2

USB-RCNT

Setting for automatic connection when USB device is disconnected

This sets whether automatic re-connection is to be initiated when the USB device is disconnected (USB reconnect).

Settings

0: No automatic connection

1: Automatic connection is initiated.

[Factory setting/value after clearing RAM: 0]

2

COPIER>OPTION>USER

Specification selection related to user mode

Sub item

Description

level.

COPY-LIM

Used to change upper limit value setting for number of sheets to copy.

Setting values

1 to 999 sheets [Factory default/After RAM clear: 999]

1

SLEEP

Used to turn sleep function ON/OFF.

Setting values

0: OFF

1: ON [Factory default/After RAM clear]

Reference:

The sleep function is set by the timer setting in the "User mode"

1

COUNTER 1

Counter status verification screen soft counter 1 setting

This makes it possible to change the type display of soft counter 1 on the control unit to suit the demand from users and

dealers.

Setting

101: Total 1

[Factory setting/value after clearing RAM: Fixed at 1 -> Cannot be changed]

1

COUNTER 2

Counter status verification screen soft counter 2 setting

This makes it possible to change the type display of soft counter 2 on the control unit to suit the demand from users and

dealers.

Setting range: 0 to 999

[Factory setting/value after clearing RAM: 108]

1

COUNTER 3

Counter status verification screen soft counter 3 setting

This makes it possible to change the type display of soft counter 3 on the control unit to suit the demand from users and

dealers.

Setting range: 0 to 999

[Factory setting/value after clearing RAM: 232]

1

COUNTER 4

Counter status verification screen soft counter 4 setting

This makes it possible to change the type display of soft counter 4 on the control unit to suit the demand from users and

dealers.

Setting range: 0 to 999

[Factory setting/value after clearing RAM: 324]

1

COUNTER 5

Counter status verification screen soft counter 5 setting

This makes it possible to change the type display of soft counter 5 on the control unit to suit the demand from users and

dealers.

Setting range: 0 to 999

[Factory setting/value after clearing RAM: 000]

1

COUNTER 6

Counter status verification screen soft counter 6 setting

This makes it possible to change the type display of soft counter 6 on the control unit to suit the demand from users and

dealers.

Setting range: 0 to 999

[Factory setting/value after clearing RAM: 000]

1

CONTROL

Switch for selecting whether to charge fees for PDL jobs

This selects whether to output count pulses to the charge management system (coin vendor or control card made by

another company) when such a system is connected.

Settings

0: Fees are not charged.

1: Fees are charged.

[Factory setting/value after clearing RAM: 0]

This item is set to "1" when fees are charged for PDL prints.

1

B4-L-CNT

Used to select whether to count B4 size paper as large size or small size for software counters 1 to 6.

Setting values

0: Small size [Factory default/After RAM clear]

1: Large size

1

COPY-JOB

Prohibits copy job reservations when card reader and coin vendor are in use.

Setting values

0: Copy job reservations [Factory default/After RAM clear]

1: No copy job reservations

1

COPIER>OPTION>BODY

Summary of Contents for iR C3380 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Page 189: ...Chapter 6 Laser Exposure...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Page 337: ...Chapter 10 10 11 F 10 11...

Page 359: ...Chapter 11 MEAP...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Page 421: ...Chapter 14 Standards and Adjustments...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006...

Page 610: ......