Chapter 2

2-9

F-2-29

Do not attach the service container:

- Inside the machine

- in the position onto which attachment of the service book container may

block off the louver area

- in the position onto which attachment of the service book container may

block off the grip area

MEMO:

In case there is no pedestal, attach the service book container on the left cover

of the main body.

<Touch Pen>

1) Place the touch pen [1] in the control panel.

F-2-30

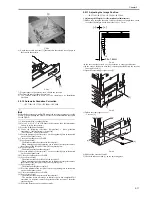

<Lower Right Cover (Lower)>

1) Hook the claws in the order of [A] and [B], and attach the Lower right

cover (Lower) [1].

(Go through this procedure when double-deck pedestal is not installed.)

F-2-31

<Stamp (Model with DADF only)>

1) Open the DADF feeder cover [1] and separation guide [2].

F-2-32

2) Using tweezers, fix the stamp in place, making sure that the print face of

the stamp faces upward.

Be sure to push in the stamp until a click is felt. The presence of a gap can

cause paper to jam.

F-2-33

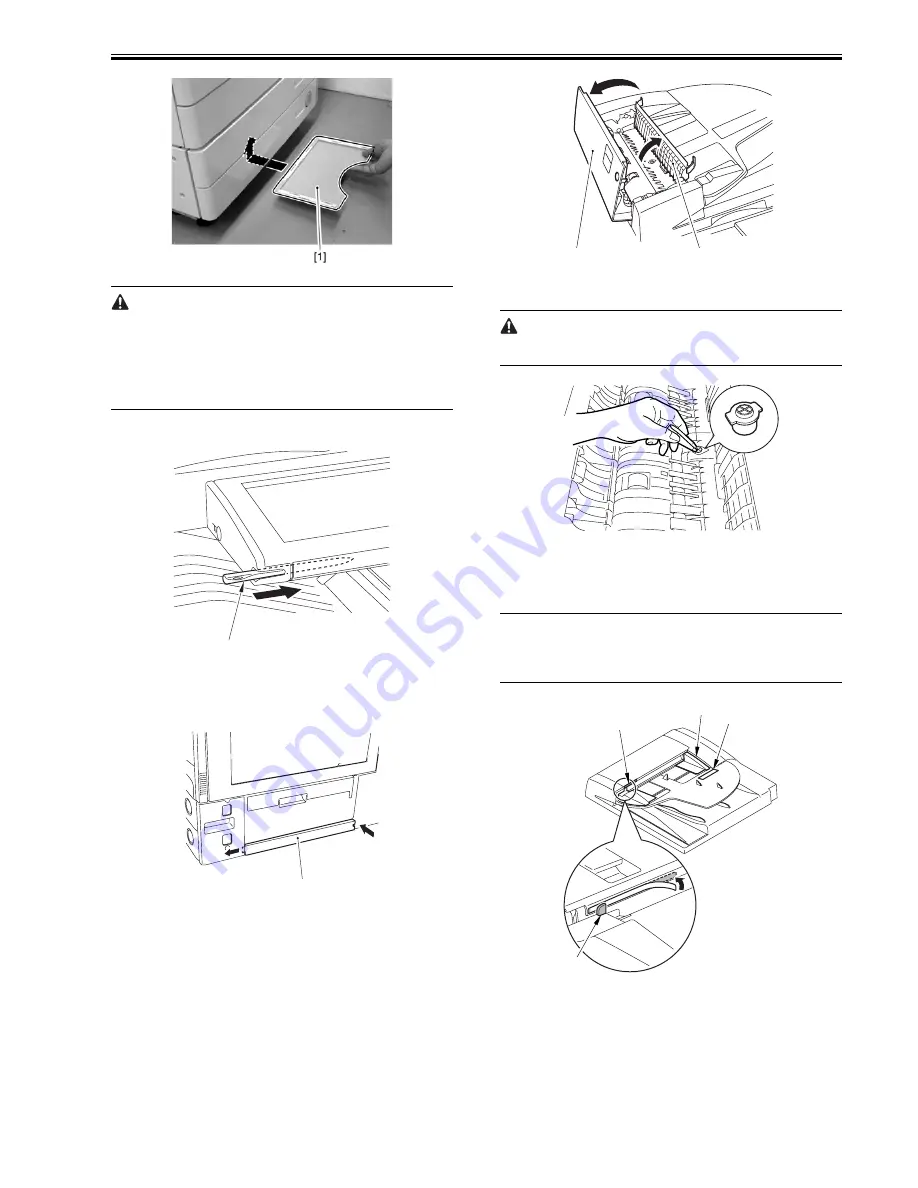

<Size Label (only if w/ DADF)>

1) Match the side guide (rear) [1] against the index A4/A3 or LTR/11X17

indicated by a marking [2].

2) Attach the size label [3] of the correct paper configuration to the feeder

cover.

MEMO:

This label is designed to help individuals needing different angles of view.

Move the label back and forth (in the direction of the arrow [5]) so that the

index [4] of the side guide (front) will match the appropriate index of the size

label.

F-2-34

[1]

[1]

[A]

[B]

[1]

[2]

[1]

[2]

[3]

ATR/11x17

A4/A3

[4]

Summary of Contents for iR C3380 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Page 189: ...Chapter 6 Laser Exposure...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Page 337: ...Chapter 10 10 11 F 10 11...

Page 359: ...Chapter 11 MEAP...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Page 421: ...Chapter 14 Standards and Adjustments...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006...

Page 610: ......