Chapter 1

48

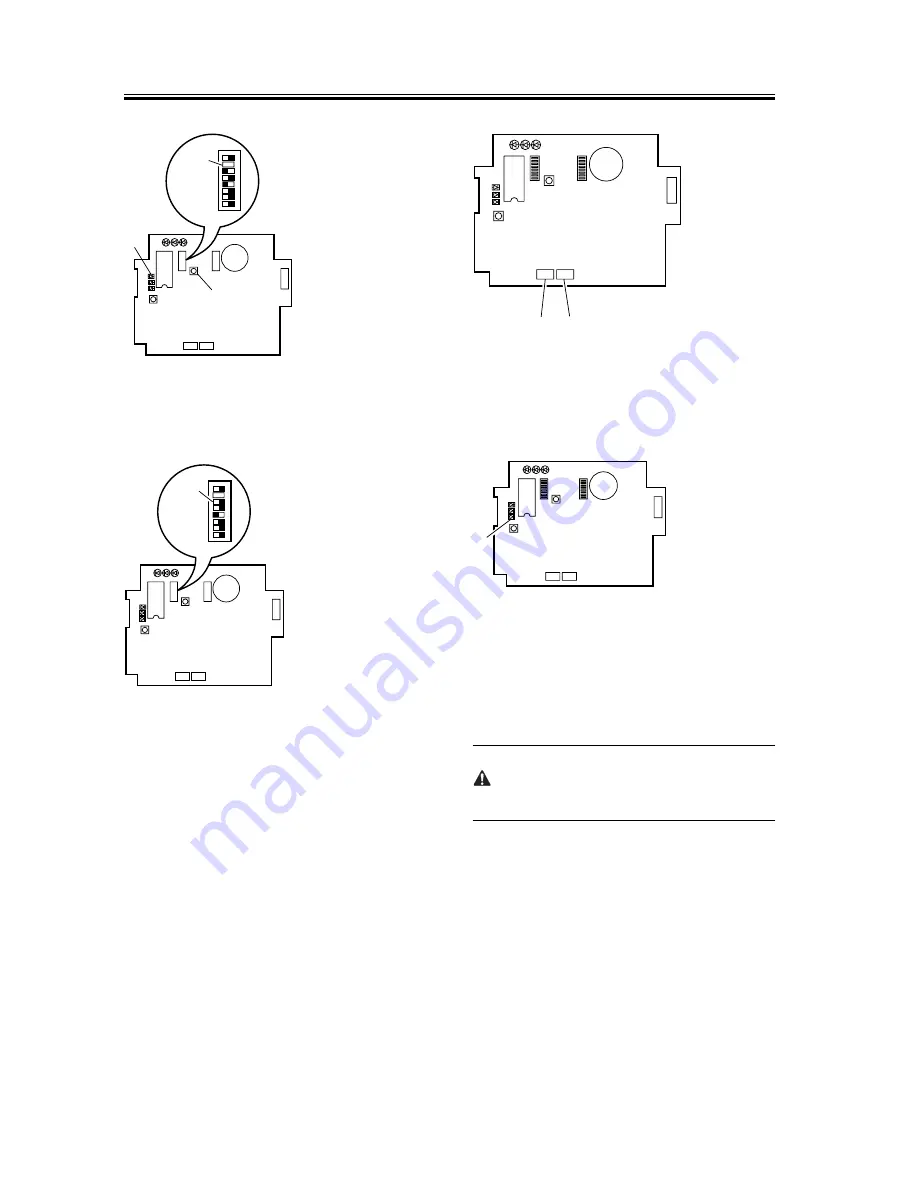

F-1-147

13) Shift bit 6 of the DIP switch (SW2-6) [1] on the

PCB to the OFF position.

F-1-148

14) Connect the telephone line to the controller.

If the controller is to be used on its own, connect the

modular jack cable to the connector (LINE) [1] of the

control. If the extension function of the controller is to

be used, connect the existing telephone or fax to the

connector (TEL) [2] of the controller while

connecting the telephone line to the connector (LINE)

[1] of the controller.

F-1-149

15) Call the service station, and ask for initial setup

work for the controller. (When a call arrives, LED4

(red) [1] starts to flash.)

F-1-150

16) Call the service station, and check if the initial

setup for the controller has ended. If the work has

failed, go through steps 10) through 12) to initialize

the RAM, and start the setup work once again.

Be sure to contact the service station to find out if

the settings are correct.

17) Call the PC at the service station using the

controller.

Press the push switch (SW4) [1] on the PCB.

A press on the push switch (SW4) [1] will cause

LED6 (red) [2] to go on; at the end of the

transmission, LED6 (red) [2] goes off. (It will flash if

the transmission fails.)

A press on the push switch (SW4) [1] while LED6 [2]

is flashing will initiate transmission once again.

LED1 LED2 LED3

2

1

LED5

LED6

LED4

IC6

SW1

SW4

SW3

6

1

BAT1

CN4

1

2

CN3

CN2

12345678

SW2

[2]

[3]

[1]

LED1 LED2 LED3

2

1

LED5

LED6

LED4

IC6

SW1

SW4

SW3

6

1

BAT1

CN4

1

2

CN3

CN2

12345678

SW2

[1]

LED1 LED2 LED3

2

1

LED5

LED6

LED4

IC6

SW1

SW4

SW3

6

1

BAT1

CN4

1

2

CN3

CN2

SW2

[2]

[1]

LED1 LED2 LED3

2

1

LED5

LED6

LED4

IC6

SW1

SW4

SW3

6

1

BAT1

CN4

1

2

CN3

CN2

SW2

[1]

Summary of Contents for iR C6800 Series

Page 1: ...Jan 20 2005 Installation Procedure iR C6800 Series...

Page 2: ......

Page 6: ......

Page 9: ...Chapter 1 Installation Procedure...

Page 61: ...Chapter 2 Relocating the Machine...

Page 63: ...Jan 20 2005...

Page 64: ......